CONTAMINATION

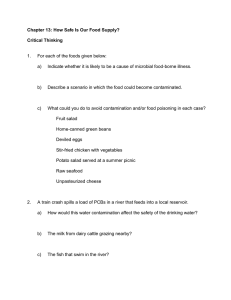

advertisement

Food Safety Controlling Contamination Focus on Low-Moisture Food Products By Brenda Stahl, Ph.D. W hen thinking of foodborne bacteria, mold and yeast outbreaks that have plagued our industry during the last 25 years, we generally reflect on items that are considered high risk: lettuce, alfalfa sprouts, beef, deli meats and soft cheeses. The explanation for these items being high-risk lay directly in the composition of the products – medium to low in fat, high in protein, and most importantly, high in available moisture. Specifically these products have a high water activity (Aw), which is defined by the ratio of water vapor pressure of food to the vapor water pressure of pure water at a specific atmosphere. More directly, this is the amount of available, free water within a food product. While microorganisms continue to change their preferences and tolerances, there is a general rule that most bacteria prefer an Aw of >0.90, whereas yeast and molds will persist in Aw >0.70. Figure 1 shows the water activity ranges for some foods, and the associated microbes that prefer to grow in those associated ranges. A food item is considered high moisture if its Aw is >0.95, medium moisture with Aw >0.85, and low moisture is generally Aw <0.84. The basic recommendation given to most food manufacturers with respect to low-moisture items was that most bacteriological issues should not be an issue, as the water activity present in these foods was refractory for microbiological growth. Given recent wide-spread contamination events, including peanut butter and peanut butter paste (Aw 0.70), cookie dough (Aw 0.80), pistachios (Aw 0.72), milk chocolate july/august 2010 AIB UPDATE 7 Food Safety (Aw 0.65) and hydrolyzed vegetable protein (Aw 0.60), the industry is now realigning its recommendations to better combat the potential for low-moisture food contamination. The concerns of these outbreaks are led primarily by Salmonella species, as well as E. coli, but are not limited in scope to these two organisms. Focusing on Salmonella in low-moisture products, a number of outbreaks of Salmonellosis have been associated with the consumption of ready-to-eat low-moisture products, including chocolate, powdered infant formula, raw almonds, toasted oats breakfast cereal, dry seasonings, paprikaseasoned potato chips, dried coconut, infant cereals and, more recently, peanut butter and children’s snacks made of puffed rice and corn with a vegetable seasoning. More than 200 cases of Salmonellosis were attributed to toasted oats cereal in 11 states between April and June 1998, more than 600 cases were attributed to peanut butter/ peanut butter paste in 47 states between August 2006 and May 2007, and more than 500 cases have been attributed to peanut butter and peanut butter-containing products in 43 states between September 2008 and January 2009. Due to the large number of unreported cases of Salmonellosis for all types of products, the actual number of cases was likely much higher. How can Salmonella and similar bacterial contamination be prevented in your low-moisture facility? We have uncovered four essential steps that, when employed, will help alleviate this potent bacteriological stressor in your products and food processing environments. STEP 1: KEEP IT DRY! The rules for cleaning and environmental control in a dry- or low-moisture plant environment are quite simple: if the environment is dry, keep it dry. It is necessary to periodically use water in some dry environments to clean certain equipment. This process removes accumulated product residue that can lead to process inefficiencies or dangerous build-ups, as well as leaving residue that becomes noticeable in the product. Due to the requirement for water usage, special considerations should be made including the review of current 8 july/august 2010 AIB UPDATE practices to help minimize water usage in dry areas, traffic flow analyses to help minimize migration of people and plant equipment (such as forklifts) from wet to dry areas, and employee compliance with Good Manufacturing Practices (GMPs). Enforce divisional rules from wet-to-dry areas, and be sure to have procedures in place if any moisture is either introduced into or forms in a dry area at any time. Maintaining a dry environment will lessen the ability for microbes to colonize within the facility, on items such as cracks, sponges, condensation gathering areas, drains, or poorly maintained air filters and fans. In review of your current practices, ensure such items as discontinuing the use of water hoses to clean during production, using a sanitizer when draining to a floor drain, and proper storage off of the floor of hoses and other materials. Evaluation of your equipment and material flow throughout the facility is important to maintaining a dry environment. Having dedicated equipment for wet/dry areas, as well as designating specific personnel and personnel clothing and equipment for each of the areas will help in keeping items from transferring between the wet and dry environments in your facility. For those workers who do travel between areas, the addition of footwear baths and drying areas outside of each area will help prevent potential carry- over into the new environment. Lastly, improving GMP knowledge and training on dedicating wet and dry areas is the first line of defense in controlling unwanted bacterial traffic. Ensure employees understand items such as dry footwear, raw material handling and proper storage, and movement of materials between dedicated areas of the facility. STEP 2: BE A MICROBIAL NICHE DETECTIVE! There are two categories of microorganisms that are present in a food process – those that are transiently introduced, and those that are resident within the products. Transient microorganisms can be introduced into food environment routes such as air flow, raw materials, uncontrolled pest contamination and a breakdown in GMPs. Routine application of GMPs and sanitation procedures is essential to remove or kill transient microflora during cleaning and disinfection. In some cases, however, certain transients can become established, multiply and persist over time. Persistent microflora can exist in biofilms or in niches in the food processing environment for decades. Biofilms occur when microorganisms become attached or immobilized on a surface, often within a matrix of microbially produced organic polymers, and provide favorable conditions for growth and survival (e.g., increased resistance to disinfectants). Biofilms are Figure 1. The Relationship Between Microbes, Aw and Food MICROBES WATER ACTIVITY FOOD E. coli Campylobacter Clostridium Listeria Aw = 1.0 Most Bacteria Staphylococcus Aw = 0.9 Molds, Yeasts Aw = 0.8 Jams, Pepperoni, Honey, Condensed Milk Salmonella Aw = 0.7 Peanut Butter and Paste, Rolled Oats, Dried Fruits, Caramel, Crackers Aw = 0.6 Dehydrated Foods Fresh Vegetables, Fruits, Meats, Fish, Milk Cured Meats, Soft Cheeses Dry Cheeses, Sugar, Syrups Flour, Cakes, Rice, Beans, Cereals Food Safety third-party laboratory, or in-house AOAC approved method for determining the presence/absence of potential microbiological hazards, and most importantly – tabulate your historical analytical data to observe changes in areas over time. Be sure to evaluate new and different areas in your facility on an intermittent basis to ensure these areas are not harboring any unwanted, persistent bacteria. By being your facility’s own “bacterial niche sleuth”, you will constantly be in control of the potential for transient contamination, and will be proactively intervening to ensure the safety of your products. The rules for cleaining and environmental control in a dry- or low-moisture plant environment are quite simple: if the environment is dry, keep it dry. common in closed systems such as in pipes and heat exchangers and on gaskets that are infrequently or inadequately cleaned. The persistence of Salmonella and Listeria monocytogenes in floor drains is largely due to the potential for biofilm formation of these two bacterial species. Niches occur in sites where food and moisture accumulate (e.g., inside the hollow supports and legs of equipment, inside hollow rollers for conveyors, in oil and grease reservoirs with worn seals, between close-fitting materials such as metal-to-metal or metal-to-plastic units). Niches are also sites that are not normally cleaned and disinfected. Biofilms and niches are of greatest concern when located after a kill step (e.g., cooking) in a process. In both cases the environment appears visually clean and will pass inspection. Traditional sampling for indicators before start of operation to verify the equipment is clean will not detect the presence of a biofilm or niche. During production, movement or vibrations of the equipment and/or flow of food through the system causes some of the microorganisms in biofilms and niches to become dislodged and contaminate the food. It is only through microbiological sampling of the equipment or food during production that biofilms and niches are revealed and corrective actions can be taken. Factors (e.g., temperature, Aw, pH, nutrient content) that influence the ability of microorganisms to multiply in laboratory media also influence the number and type of microorganisms that occur in biofilms and niches in food processing environments. Dry processes, including blending, spice manufacturing and flour milling are generally more controllable due to the lack of free moisture. More controllable does not mean free from contamination potential. Leaking roofs, pipes and hose stations and condensation that form when warm moist air contacts cold surfaces are additional sources of moisture that can occur, and these areas should be an integral part of the environmental sampling regime for the facility. Prevention of niche and biofilm formation should start with your equipment. Redesigning or replacing equipment using materials that are durable, have smooth surfaces and are easily cleanable, paired with a validated Preventive Maintenance Program, will help prevent contamination in areas that are cracked and in need of repair. The most effective strategy for detecting and controlling the influx of transient microorganisms in your facility is a robust environmental sampling program. Coordinate a facility-wide, site-specific program that periodically evaluates food and non-food contact surfaces, air-handling systems, and manufactured products themselves over a specific time interval (week, bi-monthly, month). Use an accredited STEP 3: Clean, sanitize, VALIDATE! Proper sanitation procedures are the primary line of defense against transient and problematic microbial contaminations. Ensuring sufficient training on the use of sanitizers, how to effectively clean certain food-contact areas and hard-to-reach surfaces, as well as training on the materials themselves are paramount in maintaining a truly clean work environment. Several monitoring steps should be employed in each system, including: • Visually and physically inspect food contact surfaces of equipment and utensils to ensure the surfaces are clean. • Visually and analytically monitor the water used to verify a clean, potable source. • Verify thermometer accuracy by using a calibrated thermometer when water temperature is specified. • Validate the sanitizer concentration by using the appropriate test kit for the chemical. Following direct sanitation procedures and validating the procedure on a regular basis should be fundamental to the training process for sanitation employees, as well as shift personnel in the event of an in-process line-contamination cleaning issue. Additionally, the effectiveness of sanitizers used for specific areas (stainless steel food-packaging line vs. floor drain in maintenance workshop) should be evaluated on a periodic basis. A major need for validation of sanitizer efficacy is due to the changing tolerances to bacteria in low-moisture environments. With respect to Salmonella-related outjuly/august 2010 AIB UPDATE 9 Food Safety breaks in low-moisture food items, it is necessary to set critical limits for the organism in your environment, as well as identify that these critical limits are being met and maintained by your sanitizer of choice. The efficacy of sanitizers decreases significantly over the period of their use, and should be evaluated to ensure that the perceived intervention in the facility is accurately being met. A simple efficacy test for sanitizers includes swabbing an area prior to sanitization, directly post-manufacturing. Swab the area again 2-3 hours after sanitizing, as well as every 2-3 hours until the following day’s post-manufacturing period. Evaluate the sanitizer’s ability to maintain a bacterially controlled environment. In most cases, a sanitizer will remain effective for a period of 6-12 months when used as the sole sanitizer in a given process. For optimum efficacy and longevity, use 2-3 different sanitizers for a “hurdle” effect, where the sanitizers will compete together against unwanted contamination and rotate different sanitizers in areas of the facility. STEP 4: BE A RAW MATERIAL HISTORIAN! No matter what link you may be in the food supply chain, ensuring that your suppliers are delivering safe, wholesome raw materials, ingredients or finished products is the first step in process control. “Bacterially sensitive” ingredients are ingredients that have been historically associated with a bacterial species (tested positive for the pathogen), have been implicated in past outbreaks, or are used to make products that are intended for at-risk individuals. Even in the manufacture of low-moisture products, critical evaluation of raw materials is essential in controlling your food safety program. One simple way to achieve peace-ofmind about your incoming ingredients is to invest in a Vendor Quality Program (VQP). A VQP enables your operation to systematically track performance of your vendors and verify compliance to your quality and food safety specifications to see which provide the most benefit, from both a food safety and a business perspective. Such programs include evaluation of the supplier’s food safety program with respect to pathogen environmental moni10 july/august 2010 AIB UPDATE In recent recalls a number of outbreaks of Salmonellosis have been associated with the consumption of ready-to-eat low-moisture products such as cereals and raw nuts. toring, sanitation practices, raw materials/ ingredients storage, finished product hold and release testing, process validation, and a corrective action plan if positive microbiological results are found. The first step in developing a VQP is to make certain you have a thorough understanding of your own processes and products and then understanding how your products move through the supply chain, upstream and down. This working knowledge will help you identify the key points of product receipt and transfer within your own, your vendors’ and your customers’ systems in order to best target those points where your operation’s performance tracking measures will yield the most value in terms of food safety and efficiencies. More critically, you will be able to identify ingredients or areas of concern from suppliers and be prepared to set agreeable targets and limits for product specification. In preparation for your raw materials, maintain a historical reference to their production processes, possible contamination and/or quality issues. Do not rely on Certificates of Analysis (CoA) to give you all of the background information on the product, and judge the criteria within the CoA to determine if the supplier has tested for all items that could be a concern with respect to the product and your intentional use. In March, 2010, the FDA responded to a Salmonella outbreak concerning Hydrolyzed Vegetable Protein (HVP), a common ingredient used most frequently as a flavor enhancer in many processed foods, includ- ing soups, sauces, chilis, stews, hot dogs, gravies, seasoned snack foods, dips and dressings, produced by one manufacturer with a broad supplier base. This product is a powdered, low-moisture ingredient with presumably little concern in terms of microbiological contamination. Due to the contamination found at the manufacturing site, the company is recalling all hydrolyzed vegetable protein in powder and paste form that it has produced since Sept. 17, 2009. Subsequently, all uses of this product (177 types of products as of 4/1/2010) have also subsequently been recalled and withdrawn from the market. With a strong, reliable VQP, in which the manufacturer’s processes were strongly evaluated, one would wonder if the manufacturers of those 177 different products could have avoided what is likely a major economic loss. When items that have no previous relationship to foodborne outbreaks become the vehicles of contamination in low-moisture products, a vigorous VQP can serve as your product’s security against such instances. In comparison to high-risk products, low-moisture products have traditionally been left out of bacteria-specific zerotolerance programs, such as qualified for Listeria and E. coli in the red meat industry. With the advances in bacterial persistence in low-moisture foods, we need to work cooperatively to prevent these products from continuing to catapult bacterial corruption and foodborne outbreaks in the future. AIB The author is Director of Microbiology, AIB International.