Materials and Workmanship Specification For Architectural Works

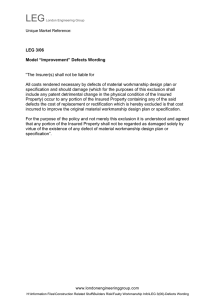

advertisement