Schedule of Work

advertisement

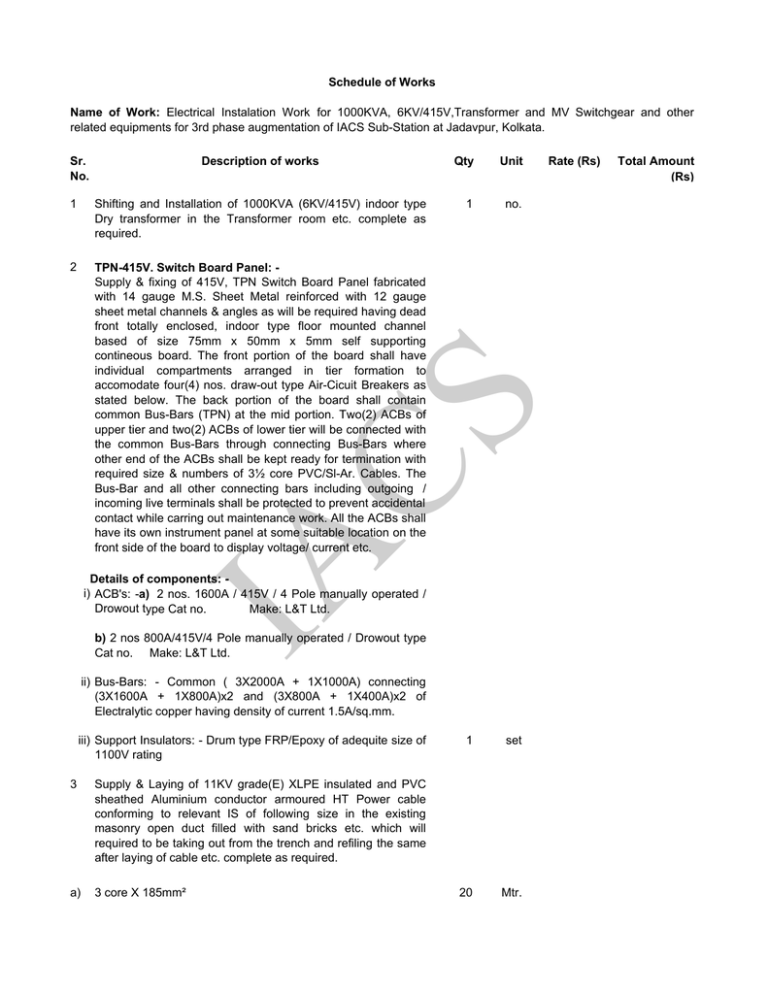

Schedule of Works Name of Work: Electrical Instalation Work for 1000KVA, 6KV/415V,Transformer and MV Switchgear and other related equipments for 3rd phase augmentation of IACS Sub-Station at Jadavpur, Kolkata. Sr. No. Description of works Shifting and Installation of 1000KVA (6KV/415V) indoor type Dry transformer in the Transformer room etc. complete as required. 2 TPN-415V. Switch Board Panel: Supply & fixing of 415V, TPN Switch Board Panel fabricated with 14 gauge M.S. Sheet Metal reinforced with 12 gauge sheet metal channels & angles as will be required having dead front totally enclosed, indoor type floor mounted channel based of size 75mm x 50mm x 5mm self supporting contineous board. The front portion of the board shall have individual compartments arranged in tier formation to accomodate four(4) nos. draw-out type Air-Cicuit Breakers as stated below. The back portion of the board shall contain common Bus-Bars (TPN) at the mid portion. Two(2) ACBs of upper tier and two(2) ACBs of lower tier will be connected with the common Bus-Bars through connecting Bus-Bars where other end of the ACBs shall be kept ready for termination with required size & numbers of 3½ core PVC/Sl-Ar. Cables. The Bus-Bar and all other connecting bars including outgoing / incoming live terminals shall be protected to prevent accidental contact while carring out maintenance work. All the ACBs shall have its own instrument panel at some suitable location on the front side of the board to display voltage/ current etc. Unit 1 no. IA CS 1 Qty Details of components: i) ACB's: -a) 2 nos. 1600A / 415V / 4 Pole manually operated / Drowout type Cat no. Make: L&T Ltd. b) 2 nos 800A/415V/4 Pole manually operated / Drowout type Cat no. Make: L&T Ltd. ii) Bus-Bars: - Common ( 3X2000A + 1X1000A) connecting (3X1600A + 1X800A)x2 and (3X800A + 1X400A)x2 of Electralytic copper having density of current 1.5A/sq.mm. iii) Support Insulators: - Drum type FRP/Epoxy of adequite size of 1100V rating 3 Supply & Laying of 11KV grade(E) XLPE insulated and PVC sheathed Aluminium conductor armoured HT Power cable conforming to relevant IS of following size in the existing masonry open duct filled with sand bricks etc. which will required to be taking out from the trench and refiling the same after laying of cable etc. complete as required. a) 3 core X 185mm² 1 set 20 Mtr. Rate (Rs) Total Amount (Rs) 4 Supply & laying of 1.1KV grade PVC insulated and PVC sheathed/XLPE armoured Power cable in the existing masonry open duct as required. a) 3½C X 400mm² 5 Mtr. Supplying and making INDOOR cable end termination with heat shrinkable jointing Kit (M-Seal/Recheme) complete with all accessories including copper lugs (Heavy duty), Heavy duty brass compression gland, suitable for folowing size of 3 core XLPE (E) aluminium conductor cable of 11 KV grade as required. i) 185sq.mm. 2 set Supplying and making end termination with Heavy duty brass compression gland including heavy duty copper socket (Dowell's) for following size of PVC insulated and PVC sheathed armoured aluminium conductor cable 1.1V grade as required. i) 3½C X 400mm² 20 sets CS 6 200 7 Earthing: 7.1 Earthing with copper earth plate 600mmX600mmX3mm thick including accessories and providing masonary enclosure with cover plate having locking arrangement and watering pipe etc. (but without charcoal or coke and salt) complete as per specifications attached herewith. sets 7.2 Extra for using salt and charcoal for G.I. or copper plate earth electrode as per specifications attached herewith (Charcoal=96 Kg & salt=5 Kg for each set). 4 sets 7.3 Providing and fixing 25mmX5mm coppr strip in 40mm dia G.I. pipe from earth electrode as per specifications attached herewith. 40 mtrs. 7.4 Providing and fixing 25mmX5mm copper strip on surface or in recess for connections etc. as per specifications attached herewith. 40 mtrs. 7.5 Providing and fixing earth bus of 50mmX5mm copper strip on surface for conections etc. as required. 2 mtr. 8 1 Job IA 4 Miscellenious / Supporting work for the above noted installation work. Total Note: The work shall be carried out as per current CPWD specifications unless otherwise specified/ decision of the Engineer-in-Charge.