Award Cutters Catalog

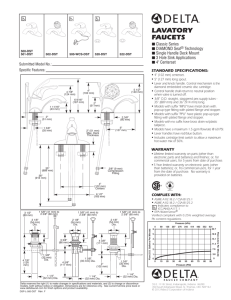

advertisement