15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER

advertisement

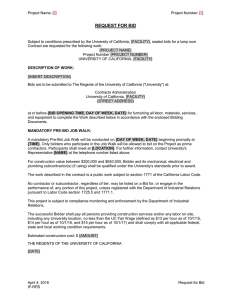

Complete Bid Package for SB-2012-18 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER SPECIFICATION Bid Due Date/Time: July 31, 2012 By 1:00 P.M. Submitted By:____________________________ Page 1 of 32 Advertised in the Claremore Progress July 8, 2012 and July 15, 2012 Invitation to Bid The Claremore Public Works Authority Electric Department will open sealed bids for the purchase of one, with the option to purchase a second, 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER, SB-2012-18, on July 31, 2012 at 1:00 P.M. in the Council Chambers located at City Hall, 104 S. Muskogee Avenue, Claremore, OK, 74017. The results will be publicly read aloud during the bid opening. A mandatory pre-bid conference is not scheduled for this bid. A bid bond is not required for this bid. The City reserves the right to waive informalities in the bids and reject any or all bids for any reason whatsoever at the sole discretion of the City. The contract will be awarded to the “lowest and best” bidder and the successful bidder will be notified in writing. Please contact Anne Smith, Central Purchasing Agent, at 918-283-1512 Ext. 131 or asmith@claremorecity.com with any questions or to receive a bid specification package. Packages are also available at http://www.claremorecity.com/bids.aspx Page 2 of 32 Anne Smith Central Purchasing Agent asmith@claremorecity.com To Whom It May Concern: You are invited to submit your sealed bid for one, with the option to purchase a second, Power Transformer for the Electric Department of Claremore Public Works Authority (CPWA). Specifications are attached hereto and are considered part of the bid package. Bids will be received in the Council Chambers, 104 S. Muskogee Avenue, City of Claremore, and are due by 1:00 P.M., “as so indicated by the time stamp clock of City of Claremore”, July 31, 2012. Sealed bids will be publicly opened and read by the City of Claremore Central Purchasing Agent or representative at 1:00 P.M., July 31, 2012, at the City Hall Council Chambers, 104 S. Muskogee Avenue, Claremore, OK, 74017. You are welcome to attend. A bid bond is not required for this bid. The City of Claremore CPWA reserves the right to accept or reject any or all received bids. Should you have any questions regarding this bid, please contact Anne Smith at asmith@claremorecity.com. Sincerely, Anne Smith Central Purchasing Agent Page 3 of 32 NOTICE TO BIDDERS The CPWA requests Bids for Bid SB-2012-18, one 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER with the option to purchase a second transformer. Acceptable candidates are: Established companies regularly engaged in these services. To receive or view specifications, contact: Anne Smith 104 S. Muskogee Avenue Claremore, OK 74017 Phone: (918) 283-1512 Ext. 131 E-mail: asmith@claremorecity.com The City Claremore Public Works Authority (CPWA) reserves the right to reject any and all bids when such rejection is in the best interests of the City of Claremore. One (1) original and four (4) copies (may be in the same package) of the bid documents should be submitted to: City Hall Central Purchasing Agent’s Office 104 S. Muskogee Avenue Claremore, OK 74017 State on the outside bottom left-hand corner of the bid envelope the following: SB-2012-18 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER Do not open until July 31, 2012 at 1:00 P.M. Due Date: Proposals must be received on or before the scheduled bid opening to be considered. Proposals received more than ninety-six (96) hours, excluding Saturdays, Sundays and holidays before the time set for opening of bids, as well as bids received after the time set for opening , will not be considered and will be returned unopened. Public Opening: Bids filed with Central Purchasing shall be publicly opened and read aloud at the time stated above and considered by the Mayor and Council in the following next available Council meeting. The opening of bids will be at the City Hall Council Chambers located at 104 S. Muskogee Avenue, Claremore, OK, 74017. Evaluation/Award: Proposals will be referred to Claremore City staff and the Engineer for evaluation. CPWA reserves the right to reject any and all bids. The successful bidder will be notified in writing. __________ Signature of Authorized Agent Date Page 4 of 32 ~ Section One ~ General Information 1.1 Purpose of the Bid The bid process is part of a competitive procurement process which will facilitate a fair opportunity for qualified firms to offer their plans and services for consideration. The City of Claremore (City) is currently seeking bids to purchase one Power Transformer for the Electric Department of Claremore Public Works Authority with the option to purchase a second transformer. The City, by means of this bid, invites all qualified bidders to submit bids in accordance with the requirements outlined in this bid. The City anticipates that, based on its review and evaluation of the proposals received pursuant to this bid, it will select a bidder and execute a contract whereby the bidder renders services to the City, in accordance with terms and conditions set forth in the contract. Pricing is to remain effective for a period of 90 days to allow Council to review and accept or reject awarded bid. 1.2 Information about the City of Claremore The City of Claremore is an innovative community near Tulsa, OK with a population of approximately 18,000 citizens. This progressive, forward-thinking city strives to offer a high quality of life that attracts industrial based businesses and employees seeking small-town charm within a major metropolitan area. The City strives to work with the citizens of Claremore to meet the needs of the community while serving everyone with respect and integrity. The City strives to do so with competence, accessibility, responsiveness, and excellence. The same level of customer service is expected of its business partners. The City is committed to its providing the highest level of amenities for the community and the region and is dedicated to the continuous improvement of its facilities. 1.3 Project Overview The equipment purchased in this bid is for the Electric Department to have installed for the Centrilift Substation project. 1.4 City’s Right to Reject The City reserves the right to accept or reject, in whole or in part, waive informalities, minor irregularities, or substitute items desired if deemed in the best interest of the City, therefore selecting the optimum proposal or issue a new bid. The City of Claremore CPWA and its designees reserve the right to determine whether a proposal is responsive and has the ability and resources to perform the contract in full and comply with the specifications. 1.5 Schedule of Events 1.6 A. B. C. D. E. F. Issue bid: July 8, 2012 Advertise in the Claremore Progress: July 8, 2012 and July 15, 2012 Proposal due date: at 1:00 P.M. on July 31, 2012 Selection of finalists: after committee review and Council approval Award: upon Council approval on the next available meeting. Selected candidate will be notified in writing. Definitions Bidder – Any Supplier providing a bid to the City of Claremore, Oklahoma. Supplier – The successful Bidder selected by the City of Claremore to supply the equipment specified herein. Manufacturer – The manufacturer of the equipment provided by the Supplier. Engineer – Finley Engineering Co, Inc, with offices in Lamar, MO. CPWA – Claremore Public Works Authority City – City of Claremore Page 5 of 32 ~ Section Two ~ Bid Requirements 2.1 Right to Modify, Rescind, or Revoke BID The City reserves the rights to modify, rescind, or revoke this bid, in whole or in part, at any time prior to the date on which the authorized representative of the City executes a contract with the successful bidder. Bidders are permitted to submit one (1) final bid per project. In the event more than one bid is received the most recent bid turned in prior to the opening will be considered. 2.2 Compliance with BID Requirements By submission of a bid, a bidder agrees to be bound by the requirements set forth in this bid. The City, at its sole discretion, may disqualify a bidder from consideration, if the City determines a bid is non-responsive and/or non-compliant, in whole or in part, with the requirements set forth in this bid. 2.3 Signature, Certification of Bidder The proposal must be signed and dated by a representative of the bidder who is authorized to bind the bidder to the terms and conditions contained in this bid and to compliance with the information submitted in the proposal. Each bidder submitting a proposal certifies to both (a) the completeness, veracity, and accuracy of the information provided in the proposal and (b) the authority of the individual whose signature appears on the proposal to bind the bidder to the terms and conditions set forth in this bid. Bids submitted without the required signature shall be disqualified. 2.4 Requirements for Submission Each bidder shall submit one (1) original – which must be clearly defined as the ORIGINAL – and (4) four copies of their proposal. The original shall be clearly readable and preferably prepared on a word processor and formatted in at least 10-point-font. The copies shall be of good, readable quality. The original and (4) four copies of the proposal shall be submitted in a sealed box or envelope, clearly state on the outside, bottom left-hand corner of the package as shown: SB-2012-18 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER Do not open until July 31, 2012 at 1:00 P.M. 2.5 Deadline for Proposals Proposals must be received by City of Claremore, Central Purchasing Agent’s office in the Finance Department by “1:00 P.M. on July 31, 2012”. Any proposal received after expiration of the deadline will be immediately disqualified from consideration. To withdraw a proposal, a written request must be made to the Claremore Central Purchasing Agent prior to the scheduled opening. 2.6 Risk of Loss, Damage, Delay Bidder acknowledges and agrees to release and hold harmless the City of Claremore CPWA, its employees, agents, and personnel, from and against any and all claims, liability, damages, and costs, including court Page 6 of 32 costs and attorneys’ fees, arising out of or pursuant to delivery of the proposal or failure to deliver the bid to the Central Purchasing Agent’s Office of the City of Claremore, as designated in Section 2.5 and 2.6 of this BID. The contractor shall hold the City harmless and shall be liable in the event of injury to City personnel or damage or loss of their property caused by the contractor's equipment, personnel supplies or material furnished. The City will not be liable for loss or damage caused by fires, lightning, sprinkler leakage, earthquake, severe weather, smoke and smudge, aircraft or motor vehicle damage, strikes, riots and civil disturbance or collapse of building or structures, etc. The City and its personnel shall not be liable for any loss of or damage to contractor property unless due to their fault or negligence. 2.7 Ownership of Proposals All proposals become the physical property of the City of Claremore upon receipt. 2.8 Use, Disclosure of Information Bidders acknowledge that the City of Claremore is a municipality of the State of Oklahoma and all bids become a matter of public record once opened. Bid with information marked “confidential” will be rejected upon discovery of such statement. By submitting a proposal, a proposer specifically assumes any and all risks and liabilities associated with the information contained in the proposal and the release of that information contained in the proposal and the release of that information by the City of Claremore for purposes related to or arising out of the (a) evaluation of bid, (b) selection of a bidder pursuant to the bid process, and (c) negotiation and execution of a contract, if any, with the bidder selected. 2.9 Costs of Participation The City of Claremore CPWA specifically disclaims responsibility and/or liability for any and all cost, expenses, or claims related to or arising out of the bidder’s participation in this bid process, including but not limited to costs incurred as a result of preparing, copying, shipping, presenting, and/or clarifying the bidder and the information relevant to the bid. 2.10 Compliance with Applicable Laws, Regulations, Ordinances, City of Claremore Policies and Procedures By submitting a bid, the bidder agrees to and shall comply with all applicable local, state and federal laws and regulations, as well as with all applicable policies and procedures of the City of Claremore. Per revisions to the Oklahoma Standards for Drug and Alcohol Testing Act effective November 1, 2011, all employers, including independent contractors, subcontractors or employees of an independent contractor, may be subject to a workplace drug or alcohol testing policy under the terms of the contractual agreement when the drug or alcohol testing policy applies to other workers at the job site or workers who are in the same or similar classification or group. ~ Section Three ~ Bid Procedures 3.1 Rescission of Bid A bid can be withdrawn from consideration at any time prior to the deadline of the bid opening, as stated in Section 2.5; pursuant to a written request sent to the City of Claremore Central Purchasing Agent’s Office. 3.2 Request for Electronic Copy A Bidder may request an electronic copy of the bid package from the City of Claremore Central Purchasing Agent’s Office. Electronic copies are available on the City of Claremore’s website www.claremorecity.com/bids.aspx Page 7 of 32 3.3 Request for Clarification The City of Claremore reserves the right to request clarification of any information contained in a bid. 3.4 Questions by Bidders and Addenda Each bidder shall carefully examine all bid documents and all addenda thereto, and shall thoroughly familiarize themselves with the detailed requirements thereof prior to submitting a proposal. Should a bidder find discrepancies or ambiguities in, or omissions from documents, or should they be in doubt as to their meaning, they shall, at once, and in any event, not later than seven (7) days prior to opening due date, notify the City of Claremore, who will, if necessary, send written addendum to all bidders. The City of Claremore will not be responsible for any oral instructions. All inquiries shall be directed to Anne Smith, Central Purchasing Agent in writing at asmith@claremorecity.com. □ Mandatory 3.5 Pre-Proposal Conference 3.7 Equipment Included in Bid Specifications ■ Not Mandatory The equipment included in this bid is as listed in the Power Transformer Specifications on page 12-22. The equipment includes one, and possibly a second, 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER. The equipment included in the Bidder’s proposal shall be of the type and quantity listed. No substitutions are allowed without prior written consent from the Engineer. 3.8 Pricing Price as an integral component of the proposal is required. The City is a tax exempt organization. Certificate of said exemption is provided in this bid package (last page). In addition to the items listed in the Bid Specifications, total bid must include FOB delivery as specified in Section 6.6. If pricing is not included within the returned packet, the packet will be disqualified as incomplete and non-compliant. All prices shall be honored for a period of 90 days to allow council to review and acceptance. 3.9 Payment The City of Claremore shall pay all invoices pursuant to 62 O.S. § 34.71. Payment will not be made on invoices submitted later than six-months (180 days) after delivery of services and any statute of limitations to the contrary is hereby waived. The City may issue itemized purchase orders, blanket purchase orders, or use the City purchasing card (MasterCard) to pay for invoices. ~ Section Four ~ Contents 4.1 Bidder Affirmation Clause Each Bidder must affirm and incorporate in its Proposal all of the Affirmation set forth in this Section 4.5. If the City of Claremore determines a bidder has submitted a false statement, in whole or in part, in regard to any of these affirmations, then the City of Claremore will disqualify the bidder from consideration and report the false statement as such to the Oklahoma Department of Commerce. Also, the City of Claremore will remove the bidder from the master bidders list of the City. Accordingly, the bidder affirms all of the following, without limitation a. The bidder has not conferred or offered to confer, either directly or indirectly, any benefit whatsoever on a public servant in connection with the submitted proposal or the subject matter of the proposal; Page 8 of 32 b. The bidder either is not subject to the payment of franchise taxes to the State of Oklahoma or is not currently delinquent in regard to the payment of franchise tax owed to the State of Oklahoma; c. The bidder, individually or acting by and through its officers, principals, employees, contractors, subcontractors, agents, or personnel, has neither (i) violated state or federal antitrust laws nor (ii) communicated any of the contents of the Proposal to its competitors or any other person or entity engaged in such line of business; d. The bidder shall defend, indemnify, and hold harmless the City of Claremore, all of its officers, agents and employees from and against all claims, actions, suits, demands, proceedings costs, damages, and liabilities, arising out of, connected with, or resulting from any acts or omissions of the bidder or any agent, employee, subcontractor, or supplier of contractor in the execution or performance of the resulting contract; e. The bidder expressly acknowledges that state funds may not be expended in connection with the purchase of an automated information system unless that system meets certain statutory requirements relating to the accessibility by persons with visual impairments. Accordingly, the proposer represents and warrants to the City of Claremore that the technology provided by bidder for purchase is capable, either by virtue of features included within the technology or because it is readily adaptable by use with other technology, of: (1) providing equivalent access for effective use by both visual and non-visual means; (2) presenting information, including prompts used for interactive communications, in formats intended for both visual and non-visual use; and (3) being integrated into networks for obtaining, retrieving, and disseminating information used by individuals who are not blind or visually impaired. For purposes of this paragraph, the phrase “equivalent access” means a substantially similar ability to communicate with or make use of the technology, either directly by features incorporated within the technology or by other reasonable means such as assistive devices or Services which would constitute reasonable accommodations under the federal Americans with Disabilities Act or similar state or federal laws. Examples of methods by which equivalent access may be provided include, but are not limited to, keyboard alternatives to mouse commands and other means of navigating graphical displays, and customizable display appearance. 4.2 Insurance Requirements The winning bidder, during the duration of this transaction, shall maintain a general commercial liability policy with limits at no less than $1,000,000 per individual loss, nor $1,000,000 aggregate. The provider of such commercial general liability shall be a reputable company authorized to transact business in the State of Oklahoma. Bidder shall furnish City of Claremore a certificate of insurance naming the City of Claremore, Oklahoma, as an additional insured on the General Commercial Liability policy, which shall include a provision that such insurance shall not be canceled without at least thirty (30) days written notice 4.3 References Submit with your bid a minimum of three (3) references of whom you have done business during the past five (5) years. They should be references who have or are currently using the products specified in your bid. They may be contacted and interviewed with regard to their overall satisfaction of product and your company’s performance. Include company name, contact name, address, phone, fax and email, estimated volume with your company and years serviced. Page 9 of 32 4.4 Approval Drawings The Supplier shall provide Approval Drawings to the Engineer. The approval drawings may be supplied in either paper form or electronic (pdf or dwg) format. Electronic form is preferred. 4.5 Submittal Requirements Each of the following Products shall be submitted by the bid time mentioned herein in order for the bid to be considered: 1. Bid specifications (pages 23-24) 2. Signed and completed Bid Form (page 25) 3. Signed and completed Non-Collusion Affidavit (page 26) 4. Signed and completed W-9 (page 27) 5. Signed and completed Notarized Sworn Statement (page 28-29) 6. Signed and completed Specifications Exception Form (page 30) 7. Verification of insurance 8. Vender Background and Qualifications 9. Information requested in Section 4.3 References ~ Section Five ~ Evaluation, Selection & Award 5.1 Discussions with Bidders The City of Claremore may conduct discussions and/or negotiations with any bidder that appears to be eligible for award (“Eligible Bidder”) pursuant to the selection criteria set forth in this bid. In conducting discussions and/or negotiations, the City of Claremore will not disclose information derived from proposals submitted by competing bidders, except as and if law requires disclosure. 5.2 Modification of Proposals Oral modifications will not be considered. Any bidder may modify their bid in writing prior to date and time of bid closing. Only modifications received in sealed envelopes with bid number, closing date and project name clearly marked on outside will be accepted. Written confirmation must be received under the same signature as prior submitted bid. All modifications are to be clearly numbered and dated as to determine the final one. 5.3 Selection of Bidder The Bidder selected for award will be the bidder whose proposal, as presented in response to this bid and as determined by the City in accordance with the evaluation criteria set forth in Section 5.5, to be the most advantageous to the City. The City reserves the right to award this contract to the “lowest and best” bidder, not necessarily to the firm with the lowest cost, but to the firm that best meets the requirements and needs of the City as determined according to the evaluation criteria. 5.4 Evaluation of Proposals This bid will be evaluated by a committee consisting of the Engineer and City personnel. Submission of a bid indicates the bidder’s acceptance of the evaluation process set forth this bid and the bidder’s acknowledgement that subjective judgments must be made by the City in regard to the evaluation process. The final evaluation and selection of a supplier will be made by the City and submitted to the Claremore City Council for approval. 5.5 Criteria for Evaluation Evaluation of bids and award to the selected bidder will be based on the following factors, as listed below: Page 10 of 32 1. 2. 3. 5.6 Cost/Fees Responsiveness to Bid Qualifications Consideration of Additional Information The City reserves the right to ask for and consider any additional information deemed beneficial to the City in evaluation of the bids. ~ Section Six ~ General Terms and Conditions 6.1 Termination Contract Termination: The City may terminate any resulting contract for cause by providing a Show Cause Letter to the contractor citing the instances of noncompliance with the contract. If the noncompliance is not cured within 10 days, the City may terminate the contract. The City reserves the right to terminate the contract for convenience by providing 15 days written notice to the contractor. 6.2 Conflicts of Interest In the event there is a potential or actual conflict of interest, the vendor(s) shall provide full disclosure to the City of Claremore. The City shall determine if the conflict, whether potential or actual, is material. 6.3 Right to Inspect The City retains the right to examine, inspect, audit, and copy, regardless of location, any and all documents, records, files, data, and information generated or utilized by the bidder in the performance of the contract. 6.4 Liens The successful bidder will not file a lien against the City and shall keep the City harmless and be liable in the event of injury to City personnel or damage or loss of their property caused by the contractor’s equipment, personal supplies or materials furnished. The City will not be liable for loss or damage caused by fires, lightening, earthquake, severe weather, smoke and smudge, aircraft or motor vehicle damage, strikes, riots, and civil disturbance or collapse of building or structures, etc. The City and its personnel shall not be liable of or damage to contractor property unless due to their fault or negligence. 6.5 Choice of Law and Venue The resulting contract shall be construed under the laws of the State of Oklahoma and venue in any action and/or litigation commenced to enforce the contract shall be instituted in the appropriate courts in Rogers County, in the State of Oklahoma. 6.6 Freight & Delivery The bidder shall include provisions for freight and delivery with the terms of FOB Destination to the City of Claremore’s substation located in Claremore, OK 74017. The cost of freight and delivery shall be included with the bidders proposal and included on the total bid and the Bid Form . Page 11 of 32 POWER TRANSFORMER SPECIFICATION PART 1 1.01 1.02 GENERAL SECTION INCLUDES A. Specifications for the manufacture and delivery of one 15/20/25 MVA Substation Transformer with the option to purchase a second of the same specifications. Bids for rebuilt transformers will not be accepted. B. The City reserves the right to evaluate similar units in operation for quality and workmanship prior to selection of the successful Bidder. The City reserves the right to waive irregularities, to reject all bids, and to select the Bid deemed by the City to be in the best interest of the City. C. Bidder must supply transformer from manufacturing facility within the United States. REFERENCES A. The transformer shall be designed, built, and tested in accordance with ANSI/IEEE, NEMA, and NFPA Standards including but not limited to the following: 1. 2. 3. 1.03 ANSI/IEEE C57.12.00 - Standard General Requirements for Liquid Immersed Distribution, Power, and Regulating Transformers. ANSI/IEEE C57.12.10 - American National Standard for Transformers Safety Requirements. ANSI/IEEE C57.12.90 - IEEE Standard Test Code for Liquid Immersed Distribution, Power, and Regulating Transformers. TESTING A. Testing shall be conducted as follows: 1. Transformer shall be fully assembled in the factory prior to testing, use of test bushings or test radiators is not allowed. 2. Testing requirements shall be conducted as per ANSI / IEEE standards, including but not limited to the following. a. Insulation Resistance (1) Each winding-to-ground and to other windings. (2) Core-to-ground (3) Surge arresters. b. Insulation dielectric loss and power factor tests of bushings and surge arresters. c. Ratio tests primary to secondary (1) All no load taps with LTC on rated (2) All LTC positions with no load on rated d. Polarity and phase-relation tests. Page 12 of 32 e. No-load loss and exciting current at rated voltage. f. Exciting current at rated voltage. g. Impedance and load loss at base 55 degrees C rating and at maximum 65 degrees C. h. Temperature rise at maximum 55 degree C rating. Records of temperature tests performed on duplicate or essentially duplicate transformers will not be accepted. i. Applied potential. j. Induced potential. k. Efficiency at all KVA ratings l. Winding resistance on all rated voltage and all no load tap positions. 1.04 SUBMITTAL A. The following shall be submitted to the Engineer for Approval: 1. Approval Submittal a. Shop Drawings: Include wiring schematics with connection diagrams. b. Product Data: Provide data showing dimensions and ratings for components. c. Manufacturer's Instructions: Indicate application conditions and limitations of use stipulated by product testing agency specified under Regulatory Requirements. d. Include instructions for storage, handling, protection, examination, preparation, and installation. e. Warranty/Guarantee. 2. Final Submittal a. Operation and Maintenance manuals. Four (4) copies each complete with drawings are to be submitted to the Owner. b. Drawings to include the following: (1) Outline diagram (include sample with bid) (2) Transformer nameplate (3) Schematic diagrams (4) External Connection diagrams (5) Internal Connection diagrams (6) Drawings shall be submitted in AutoCAD 2007 format (7) Certified test reports. Page 13 of 32 PART 2 2.01 PRODUCTS GENERAL REQUIREMENTS A. Equipment: 1. Factory assemble to full extent possible for minimum field reassembly. 2. Furnish new equipment, of first-class construction conforming to best modern practice. 3. Supply all necessary material such as insulating oil, bolts, nuts, washers, wiring materials, etc. as require for complete field assembly and installation. 4. Silverplate or tinplate all primary current connections and joints. 5. Provide engraved laminated plastic nameplates for each instrument or control device mounted on the equipment. 6. Tag and package separately all spare parts and tools. Identify on Bill of Lading as “Owner’s Spare Parts”. B. Control Wiring 1. Completely install all internal control wiring at the factory. 2. Make all connections at equipment studs or terminal blocks. Terminate all CT leads on short circuiting type terminal blocks. Terminate all other leads on manufacturer’s standard type terminal blocks. 3. Terminate all points requiring external wiring connections at numbered points on terminal blocks conveniently grouped to receive the Owner’s cables. 4. Install internal wiring in horizontal and vertical wireway designed for easy accessibility to interior panel wiring. Wiring bundles may be used where wireway is not easily installed. 5. Provide all wiring necessary for all equipment specified, and for wiring for future equipment where such wiring is specified. 6. Factory test all wiring for grounds, opens and proper continuity, and for proper operation of all relays, meters, instruments, switches, lights and interlocks. 7. Wire all spare contacts on control switches, auxiliary relays, and alarm devices to external connection terminal blocks. 8. Install all internal wiring without splices. 9. Provide extra flexible hinge wire in areas subject to flexing, such as on hinged brackets or swing racks, if used. 10. Terminal blocks: a. Use heavy-duty terminal blocks rated at least 30 amperes, 600 volts. b. Identify each terminal on each block by stamping or marking the terminal designation permanently on the block. c. Mount terminal blocks in vertical rows on interior sides or divider panels with means for cleating external control cables which enter from the bottom. Allow for cable entry. d. Provide terminal blocks with identification to provide at least 24 spare terminals having no internal connections or designated future connections. 11. No more than two wires shall be terminated at any one terminal point. 12. All control wiring shall be terminated with preinsulated ring-tongue compression terminal lugs. 13. Provisions to prevent chafing shall be provided at all entrances and exits of conduit. C. Finish: 1. Apply finish to all steel surfaces of equipment. Finish shall follow ANSI standards. Page 14 of 32 2. 3. 4. 5. 2.02 Clean and treat surfaces with phosphatizing process or equal and apply all necessary filler before application of finish. Apply at least one coat of corrosion resistant primer, having a minimum dry film thickness of 2 mils, and at least two finish coats as indicated, each having a minimum dry film thickness of 1-1/2 mils. Apply exterior finish coats in ANSI 70 gray. Finish coats on the interior of cabinets shall be white. Provide durable non-skid surface on transformer tank top and LTC compartment top. TRANSFORMER EQUIPMENT AND MATERIALS A. Type and Design: 1. Design shall conform to references listed herein and other applicable ANSI / IEEE standards. a. Base: Construct of structural steel shapes and/or plate to form a rigid skid on which the transformer can be slid or rolled on either main centerline axis. b. Provide jacking provisions for lifting complete transformer. c. Provide pulling eyes for pulling transformer. d. Tank Assembly (1) Welded steel plate construction (2) Constructed without corner welds on the main tank. Tank seams shall be double welded (inside and outside) and shall be a minimum of 6” from the corner. All welds shall be cleaned and ground smooth prior to surface coatings. Tank bracing shall be sealed tubular construction. (3) Absolutely oil and gastight with all fittings in place. (4) Capable of withstanding without permanent deformation pressure 25 percent greater than the maximum operating pressure resulting from the oil preservation system per ANSI standard. (5) Suitable for full vacuum filling and vacuum drying. (6) Provided with tanking guides for centering core and coil assembly. (7) Gasketed joint to have machined surfaces on both sides, with gasket retainers and metal-to-metal stops, to assure even and effective pressure, avoid overstressing gasket, and to maintain oil tightness of joint under all service conditions. (8) Gasketed joints on transformer shall be raised above cover. (9) Provide a minimum of two 24” diameter manholes with bolted covers in top of transformer for access to lower ends of bushings, terminals, upper portions of coils, core ground, and to permit replacement of current transformers and other auxiliaries without removing the tank cover. Manholes shall be round. Manholes shall be located so as not to require removal of other accessories to permit access. Manhole covers shall be furnished with handles. (10) The transformer shall be designed and capable of withstanding, mechanically and thermally, a maximum terminal short circuit current from an “Infinite Bus” (Zero impedance source) that can flow in any winding for a period of 0.5 seconds due to a fault. Page 15 of 32 (11) (12) (13) (14) (15) (16) (17) e. f. B. Have adequate bracing of core and coils to withstand handling, shipping, normal and through fault operating forces. Core ground connection shall be accessible without lowering oil level (locate above oil). Combination 2” globe type drain and lower filter valve within 1” of the bottom of the tank with 3/8” or ½” sampling device valve. Valve to be furnished with removable plug and cap devices. One (1) inch minimum upper globe type filter valve below the oil elevation of the liquid level gauge. Valve to be furnished with removable plug. All accessory supports shall be adequately supported to provide a stable assembly. Supports for arresters shall be designed to resist a 40 pound per square foot wind loading on the arresters. The shipping center of gravity shall be plainly indicated and dimensioned on the outline drawing and marked on the transformer tank sides and cover. The completely equipped and oil filled center of gravity shall be plainly indicated and dimensioned on the outline drawing only for use in foundation design. Coils: (1) All main and auxiliary coils shall be circular shape. (2) All main and auxiliary coils shall be disk or helically wound. Core and Coil Assembly: (1) Joints in windings or at bushings: Brazed or clamped, not soldered. (2) Rigidity: Assembly to be braced or bolted adequately to prevent displacement or distortion under all normal conditions of handling and operation under short circuit conditions. (3) Inside bolted connections: Locking type connections required. (4) Insulation on all conductors used in the coil winding process shall be cellulose insulating paper. (NOMEX is an approved equal.) It shall be wound onto the conductor employing a spinning process. The paper insulation shall be applied in single or multiple strands such that a minimum of 30% of the paper surfaces are overlapped to provide for a continuous insulating surface. Sufficient tension shall be maintained on the paper strands so as to prevent loose wraps. All coils shall include full circumference clamping rings. Core and coils shall be dried using a “vapor phase” system prior to filling with oil. The insulating material, varnishes, and other associated compounds shall not contaminate the insulating oil, nor shall these items be affected by the oil. (5) The ampere rating of all leads shall provide adequate ampacity through the highest 65°C rating. The Xo neutral lead shall not be sized smaller than the X1, X2, and X3 leads. All leads shall also provide adequate ampacity capacity for loading conditions described in IEEE C57.92. Transformer Design Criteria 1. Three phase transformer shall have the following ratings and electrical characteristics: Page 16 of 32 a. b. c. d. e. f. g. h. i. j. C. Transformer type: Two winding, Delta High Side - Wye Low Side, Outdoor type, Oil immersed OA/FA/FA. Continuous Rating: 15/20/25 MVA OA/FA/FA at 55 deg. C rise with 12% supplemental at 65 deg. C rise Frequency cycle: 60 hz Voltage: 67000 - 13200Y/7620 High Voltage Taps: 70600; 68800; 67000; 65200; 63400 Volts with external tap changer for changing taps while transformer is de-energized. BIL rating: 350 KV primary; 110 KV secondary; 110 KV neutral. Impedance: 8.0 % Nominal at 15 MVA plus/minus 10%. Oil Preservation System: Sealed tank system with (gas-oil) nitrogen blanket with tank pressure-vacuum safety bleeder device set to operate at maximum positive and negative pressures indicated on nameplate. Provide one (1) filled nitrogen bottle (non-returnable). Bottom of bottle shall be within 6” of top of foundation. Provide all necessary tubing and a sampling valve. Bushing CT’s: (1) Primary: two (2) 600:5 CT’s per bushing. (2) Secondary: two (2) 2000:5 CT’s per bushing. (3) Neutral: one (1) 600:5. (4) All CT’s multi-ratio; relay accuracy C400. [Thirteen total CT’s not counting LTC CT’s.] All CT’s shall be pre-wired to shorting type terminal blocks in the control compartment. DC control voltage – 125 Volts Transformer Components and Accessories 1. In addition to accessories required under ANSI C57.12.00 and ANSI C57.12.10, the transformer shall have the following accessories: a. Surge Arresters (1) Primary: Three (3), station class, 54KV rated 42KV MCOV (2) Secondary: Three (3), station class, 10KV rated 8.4 MCOV (3) Arresters shall be ANSI 70 Gray, porcelain, MOV. (4) Furnish all standard accessories, including base, cap, NEMA 4hole pad standard silicon-bronze flat terminal, mounting bolts, lockwashers, and grounding equipment. b. Bushings (1) High Voltage: 69KV, 350KV BIL, draw lead. 5 Foot Minimum Spacing. (See Dwg XFMR-001) (2) Low Voltage: 15KV, 110KV BIL, solid lead. 2 Foot Minimum Spacing. (See Dwg XFMR-001) (3) Shall be condenser (oil filled) type and shall be free of oil leakage and shall have suitable leak-proof sight gauges and with a convenient means for sampling oil and draining the bushings at the mounting flange location. (4) Furnish a 4-hole NEMA standard silicon-bronze flat terminal. Bushing terminal connectors shall be furnished with tinned surfaces. (5) Each bushing shall have a power factor tap for testing purposes. (6) All bushings shall be designed such that impulse voltage flashover occurs outside the tank before flashover occurs on the bushings inside the transformer. Page 17 of 32 (7) c. d. e. f. g. h. Each bushing shall have the bottom portion suitably covered with an easily removable weatherproof coating to permit outdoor storage. Sudden Pressure Relay: (1) Quantity: two (2), one for main tank and one for LTC. (2) Provide 125-volt DC seal-in relays internally wired in the control cabinet on the transformer. (3) The sudden pressure relay and seal-in relay shall be provided with circuitry to effectively prevent false indication of relay operation due to induced voltages in the control wiring. (4) The sudden pressure device shall have means for field testing with a separate pressure source. (5) Wire the seal-in relay terminals to terminal blocks for the Owner’s external connection. (6) Sudden pressure seal-in relay shall be Qualitrol Model 909-200-01 Pressure Relief Device: Quantity: one (1) for main tank. Equal to Qualitrol. Provide with alarm contacts, operation set for 10 psi nominal, provide long arm, yellow semaphore for visual indication. Magnetic Liquid Level Gauge: With alarm contacts for low level; wire to control cabinet. Gauge to be located on Side 1 (See Dwg XFMR-001) above the control cabinet. Pressure-Vacuum Gauge: With alarm contacts for “high” and “low” pressure. Dial Thermometers (1) Dial type thermometer with multiple field adjustable alarm contacts for high oil temperature. All contacts shall be individually adjustable to any temperature between 50 to 125 degrees C. (2) Winding temperature indicator: Quantity: Two (2) equal to Qualitrol with adequate contacts for cooling control plus one alarm contact for a high temperature alarm. All contacts shall be individually adjustable to any temperature between 50 to 125 degrees C. (3) Dial indicators shall be located for easy readability. Gauges shall be mounted at a height of 78” or lower. Gauges shall be mounted on Side 1 (See Dwg XFMR-001) to the left of the control cabinet as shown. Gauges shall be aligned vertically with oil temperature guage at the top, High Voltage winding temperature gauge in the middle and Low Voltage winding temperature gauge on the bottom. (4) Provide resettable drag hand on all dial thermometers. Cooling Equipment and Controls (1) Radiators shall be capable of withstanding, without damage or permanent deformation, the vacuum and pressure conditions specified for the tank assembly. (2) Furnish each cooler unit with a lifting eye, and oil drain at the bottom, and a vent at the top (3) Radiators and fans shall be completely interchangeable among cooler units. (4) Use of heat exchangers in lieu of radiators is not acceptable. Page 18 of 32 (5) D. Cooling fans shall be located to be readily accessible for inspection and repair. Fan motors shall be 240 VAC, 3 wire, 1 phase. Each fan motor shall be furnished with a disconnecting device to permit removal of the fan without de-energizing the entire cooler group. Cooling fans shall be Krenz-Vent, no subsitutes. (6) Tank-mounted radiators shall be removable type with flanged lockable valve fittings. (7) Radiators to be located on Side 3 (See Dwg XFMR-001). If radiators are required on two sides, then additional radiators are to be placed on Side 4. i. High Voltage de-energized tap changer handle located not higher than five (5) feet with padlock provision. j. Grounding: Two (2) welded on ground pads for grounding transformer, with bolted connectors suitable for Owner attachments for #4/0 copper cable, one each located six (6) inches up from bottom of tank on two opposite corners. Manufacturer shall connect 4/0 stranded copper cable from one ground pad up to neutral bushing, low voltage lightning arresters, high voltage lightning arresters, down to opposite ground pad. Cable shall be securely attached to transformer tank at intervals not to exceed eighteen (18) inches. k. Provide a 12 point, 125 volt DC alarm annunciator. Rochester Part No. AN-3196B-F2M1, no substitutes. k. Lifting facilities for cover, core and complete transformer. l. Transformer cover shall be welded to the tank. m. Transformer cover shall be slightly domed to shed water. Load Tap Changer 1. Tap changer shall be capable of energized and fully loaded operation through a tap selector switch, contactor mechanism, and impedance device as specified. 2. Tap changer equipment shall provide automatic plus and minus 10% adjustment of the low voltage in 32 equal 5/8% steps. 3. Rated for 28 MVA on all tap positions. 4. The tap changer mechanism’s current carrying contacts shall be capable of 500,000 operations before contacts need to be replaced. 5. Switching mechanism shall be enclosed in a separate compartment with a hinged access cover from the main transformer tank and shall not in any way share the same insulating oil with main core and coils. 6. Provide raise and lower switches for manual operation 7. Provide auto-manual selector switch. 8. Control Compartment: a. Provide terminal board in control compartment for termination of external wiring. b. Provide heater with switch and thermostat. c. Motor and controls protected by circuit breakers. d. Drill plate in bottom of compartment. 9. Provide resistance or vacuum type LTC. Arcing tap switch involving direct arcing of the insulating liquid is not acceptable. Approved types include Magnetek type UZD or Reinhausen type RMV. 10. Tap changer shall include the following: a. External position indicator with electrically resettable drag hands. b. Provision for manual (hand-cranking) operation. c. Operation counter. Page 19 of 32 d. e. 11. E. F. On-position and off-position contacts. On-position indicator with maximum and minimum indicating hands equipped with electrical resetting capable of operation by personnel standing at the base of the transformer. The position indictor shall be readable while operating the LTC manually. f. Beckwith M-2001C-6EL Digital Tap Changer Control, no substitutes. g. Beckwith M-2067 adapter panel, no substitutes. h. Beckwith M-0329B LTC Backup Control, no substitutes. i. Selsyn position transmitter wire to terminal blocks j. Lockage weatherproof compartment for motor drive and control equipment, including space heater, light, and convenience outlet. k. Sudden pressure relay and accessories as specified for main tank, including nameplate, liquid level gauge, pressure relief device, etc. l. Operating mechanism with motor drive. m. Motor and controls protected by circuit breakers. n. Voltage testing terminals. o. Controls and time delay relays. p. Line drop compensator with resistance and reactance adjustments. q. Reactance reversing switch. r. Current transformer with line drop compensator. Tap Changer cabinet and Motor drive to be oriented on Side 2 (See Dwg XFMR001). Bottom of LTC cabinet shall be a minimum of 90” above transformer base. Bottom of LTC motor drive shall be a minimum of 50” above transformer base. LTC tap gauge to be oriented on Side 1 (See Dwg XFMR-001) Insulating Oil 1. Furnish high-quality, high dielectric strength, stable insulating oil suitable for the operating temperature specified. 2. Insulating oil for use in electrical equipment shall be free from additives of any kind, either natural or synthetic. 3. The Manufacturer shall submit to the Owner, with his proposal, certification that the insulating oil to be furnished does not contain any mixture of polychlorinated biphenyls (PCB’s) as determined by laboratory analysis and test procedures recommended by the EPA. 4. Insulating oil shall meet the following requirements: a. Non-PCB b. Minimum dielectric strength 30-kV per ASTM D-1816. c. Maximum power factor of 0.05% per ASTM D-924 d. Minimum interfacial tension of 40 dyne/cm per ASTM D-971 e. Maximum moisture in oil of 15 ppm after processing per ASTM D-1535 5. Oil not meeting this requirement shall be replaced at the Manufacturer’s expense. Control Compartment 1. Provide a weatherproof, utility-grade, control cabinet for all auxiliary power, alarm, and current transformer external connections. a. Provide removable plate on bottom of control cabinet to facilitate field drilling for conduit entrance. b. Furnish hinged, gasketed, double access control cabinet doors complete with guides to hold doors open. Cabinet latch and hinge hardware shall be stainless steel. Hinges shall be full length. c. Sub-panels shall be hinged. Page 20 of 32 d. 2. 3. 4. 5. 6. 7. 8. PART 3 3.01 EXECUTION WARRANTY A. 3.02 Furnish cabinet ventilation to prevent heat build-up in cabinet. Provide filter and screen to prevent infiltration of contaminants and dust into control cabinet. e. Provide a duplex receptacle, protected by a ground fault interrupting (GFI) circuit breaker, in the cabinet. f. Furnish a light with switch. g. Provide a drawing pocket on inside of door. Minimum wire sizes: a. CT Circuits - #10 SIS b. Internal control wiring - #12 SIS c. Internal power wiring - #12 THHN Provide branch breaker disconnects for each AC subfeed. Include sub-fusing for branch power circuits (GFCI receptacle, space heaters, working lights, auxiliary fans, other items). a. Motor and accessory voltage – 240VAC, 3 wire, single phase b. Space heaters / lighting and outlet – 120VAC, 2 wire, single phase Minimum enclosure size is 40” (W) by 40” (H) by 24” (D). Submit typical schematic with bid for evaluation. Low voltage motors, (fans, pumps) shall operate at 115/230 VAC, single phase, three wire. Control Compartment to be located under the low voltage bushings on Side 1 (See Dwg XFMR-001) Control Compartment to contain: a. Potter and Prumfield relays for undervoltage relays. b. Undervoltage relay for Owner’s PT supply. c. Vacuum Interrupter Monitor – Provide alarm contacts in control cabinet for Owner’s use. d. Only gray Panduit is acceptable. e. All breakers and devices shall be labeled with a phenolic nameplate that contains the device number and a short description. f. All indicating lights shall be LED. g. Provide separate switches for LTC raise/lower and auto/manual. Warranty shall extend for a minimum period of one year extending to all components, including labor, and full coverage of transportation “in and out costs”. Warranty period shall begin the earlier of 180 days from the date of delivery, or the date the Owner places transformer “on-line”. LOSSES A. B. Loss evaluation rates are as follows: no load losses @ $8000/KW; load (copper winding) losses @ $2000/KW (@ 15MVA base rating); auxiliary losses @ $1000/KW @ 15MVA base rating In the event the transformer furnished under this proposal fails to meet the loss guarantees submitted by the Bidder, an adjustment in the price will be made at the evaluation rates listed above. Page 21 of 32 3.03 SHIPMENT A. B. 3.04 F.O.B. Substation site, Claremore, Oklahoma, ready for offloading by Owner’s Contractor in fully functional state ready for energized use. If transformer must be shipped partially assembled, (i.e., without oil, radiators, and/or bushings), Manufacturer shall provide at no additional cost, qualified personnel, equipment, and tools as necessary to complete assembly. [Owner will furnish lift truck and general labor to assist with lifting and placement of bushings, radiators, etc; however, Manufacturer shall supervise and be responsible for completing assembly.] Transformer delivery will not be accepted any sooner than March 2013. SPARE PARTS A. Provide the following spare parts: One (1) spare cooling fan complete with blade, cage, and cord One (1) gallon interior and exterior touch up paint Special wrenches / tools standard with manufacturer. Spare set of gaskets for transformer END OF SPECIFICATION Page 22 of 32 Manufacturer’s Proposal Information to be submitted with Bid: Manufacturer/Factory Location ___________________________ No-Load (Core) Losses @ 100% rated voltage ___________________________ Load (Copper) Losses @ Base Rating (15MVA) ___________________________ % Regulation at 100% P.F., 15 MVA ___________________________ % Regulation at 80% P.F., 15 MVA ___________________________ Impedance, % on Own Base Z1% ___________________________ Z0% ___________________________ Total weight of unit, including oil and complete assembly ___________________________ Height over cover (Tank Height) ___________________________ Height over 69 KV bushing ___________________________ Height over Low Voltage Bushing ___________________________ Transformer Tank Base Dimensions ___________________________ Shipping Weight ___________________________ Total Weight ___________________________ Proposal Outline Drawing ___________________________ Insulation System ___________________________ Gallons of Oil required ___________________________ Oil being shipped in transformer? ___________________________ Oil Manufacturer and Type ___________________________ LTC Manufacturer and Model ___________________________ Can LTC be manually operated, safely, without de-energizing the transformer? ___________________________ Bushing Manufacturer (s) High ___________________________ Low ___________________________ Page 23 of 32 Lightning Arrester Manufacturer (s) High ___________________________ Low ___________________________ List Components to be assembled on site (shipping splits, etc.) BID SUMMARY ITEM 15/20/25 MVA 65º C 67-13.2 kV LTC Power Transformer LEAD TIME QTY. EXTENDED PRICE UNIT PRICE 1 FREIGHT: (FOB Destination) TOTAL EXTENDED PRICE: Option #1: 15/20/25 MVA 65º C 67-13.2 kV LTC Power Transformer 1 OPTION #1 ADDITIONALFREIGHT: (FOB Destination) TOTAL EXTENDED PRICE INCLUDING OPTION #1: Page 24 of 32 Bid Form for 15/20/25 MVA, 65°C, 67-13.2 kV LTC TRANSFORMER(S) SB-2012-18 All bids must meet or exceed specifications or it will be rejected. The Undersigned Acknowledges: 1. That he/she is an authorized agent of the vendor submitting this bid. 2. The receipt of the following Addenda; if none was received, mark N/A_______________________________________________________________________ 3. The firm submitting this bid has never defaulted on any Municipal, State, Federal, or Private Contract. Company: _______________________________________________________________________ Signed By:_______________________________________________________________________ Printed or Typed Name: ____________________________________________________________ Address: ________________________________________________________________________ Telephone Number: _______________________Fax Number: _____________________________ Toll Free Number: ______________________E-Mail: ___________________________________ Cell Phone Number:_____________________Pager:_____________________________________ Primary Point Of Contact:__________________________________________________________ Payment Terms And Conditions:_____________________________________________________ Total bid (Sub total + Freight and Delivery): $____________________________________________________________________________ Total Bid written in words:_________________________________________________________________________ 104 S. Muskogee P. O. Box 249 Claremore, Oklahoma 74018 Phone: (918) 341-1325 Fax: (918) 341-7705 Page 25 of 32 NON-COLLUSION AFFIDAVIT BUSINESS RELATIONSHIPS AFFIDAVIT STATE OF OKLAHOMA ) )SS. COUNTY OF ____________) __________________________________________, of lawful age, being first duly sworn, on oath, says that (s)he is the agent authorized by the bidder to submit the attached bid. Affiant further states that the nature of any partnership, joint venture, or other business relationship presently in effect or which existed within one (1) year prior to the date of this statement with the architect, engineer, or other party to the project is as follows: _______________________________________________________________________ _______________________________________________________________________ Affiant further states that any such business relationship presently in effect or which existed within one (1) year prior to the date of this statement between any officer or director of the bidding company and any officer or director of the architectural or engineering firm or other party to the project is as follows: _______________________________________________________________________ _______________________________________________________________________ Affiant further states that the names of all persons having any such business relationships and the positions they hold with their respective companies or firms are as follows: _______________________________________________________________________ _______________________________________________________________________ (If none of the business relationships hereinabove mentioned exist, Affiant should so state.) Name & Title ______________________________________ Address ______________________________________ County of ______________________________________ State of ______________________________________ Subscribed and sworn to before me this ______ day of _______________, 20___. Notary:______________________________________________________ My commission expires: ___________________________________ Page 26 of 32 Page 27 of 32 Notarized Sworn Statement (Contract) STATE OF OKLAHOMA ) ) SS COUNTY OF ) ____________________________ , of lawful age, being first duly sworn, on oath says: 1. (s)he is the duly authorized agent of __________________, the contractor under the contract which is attached to this statement, for the purpose of certifying the facts pertaining to the giving of things of value to government personnel in order to procure said contract; 2. (s)he is fully aware of the facts and circumstances surrounding the making of the contract to which this statement is attached and has been personally and directly involved in the proceedings leading to the procurement of said contract; and 3. neither the contractor nor anyone subject to the contractor’s direction or control has paid, given or donated or agreed to pay, give or donate to any officer or employee of the State of Oklahoma any money or other thing of value, either directly or indirectly, in procuring the contract to which this statement is attached. Name & Title ______________________________________ County of ______________________________________ State of ______________________________________ Subscribed and sworn to before me this ______ day of _______________, 20___. ____________________________________________ Notary Public My Commission Expires:________________________ (SEAL) Page 28 of 32 INTEREST AFFIDAVIT STATE OF OKLAHOMA ) )SS. COUNTY OF ____________) I, __________________________________________, of lawful age, being first duly sworn, on oath, state that I am the agent authorized by the seller to submit the attached bid. Affidavit further states that no officer or employee of the City of Claremore either directly or indirectly owns a five percent (5%) interest or more in the Candidate’s business or such a percentage that constitutes a controlling interest. Affidavit further states that the following officers and /or employees of the City of Claremore own an interest in the Candidate’s business which is less than a controlling interest, either direct or indirect. ___________________________________________________________________________________________ ___________________________________________________________________________________________ Name & Title _____________________________________________________ Subscribed and sworn to before me this _______ day of _____________________, 2012. ____________________________________________ Notary Public My Commission Expires:________________________ (SEAL) Page 29 of 32 CITY OF CLAREMORE, OKLAHOMA SPECIFICATIONS EXCEPTION FORM In the interest of fairness and sound business practice, it is mandatory that you state any exceptions taken by you to our specifications. It should not be the responsibility of the City of Claremore to ferret out information concerning the materials which you intend to furnish. If your proposal does not meet all of our specifications you must so state in the space provided below: ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ __________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ __________________________________________________________________________________________ Proposals on equipment, vehicles, supplies, service and materials not meeting specifications may be considered by the City, however, all deviations must be listed above. If your proposal does not meet our specifications, and your exceptions are not listed above, the City of Claremore may claim forfeiture on your proposal bond, if submitted. Signed:__________________________________________________________________________ I DO meet specifications. Signed: _________________________________________________________________________________ I DO NOT meet specifications as listed in this proposal; exceptions are in the space provided. *Failure to submit this form with your proposal response may result in your proposal being rejected as unresponsive. Page 30 of 32 In an effort to better reach all prospective vendors, please assist us by providing and returning, with your bid/proposal, the following information: How did you learn about this request for proposal? Please check all that apply: ________ Legal notice in the Claremore monitor ________City of Claremore internet web site ________ Advertisement on Claremore cable TV. (CCTV-Channel 17) ________ Posting on city hall bulletin board ________ Subscription to a construction reporting service if ________City sent the bids to my firm ________ Other, please identify_____________________________________________ Thank you for your assistance! *This form is a questionnaire and not a necessary component of the bid submission. Bids will not be rejected on the grounds of this form not being completed. 104 S. Muskogee P. O. Box 249 Claremore, Oklahoma 74018 Phone: (918) 341-1325 Fax: (918) 341-7705 Page 31 of 32 Page 32 of 32