Safety is always a key concern. Organisation and

advertisement

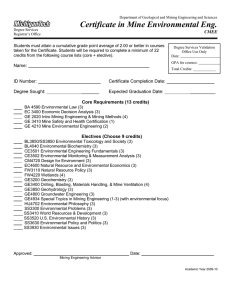

SAFE AND SOUND:proof 22/11/08 14:11 Page 1 MINE SAFETY Safe and sound The laser scanning system supplied by 3D Laser Mapping to the Damang mine includes a Riegl LMS Z420i long range laser scanner, which can capture up to 11,000 point measurements per second, to an accuracy of 10 mm and at a range of up to 1,000 m. A rugged and fully portable sensor, the system also includes a calibrated and accurately orientated high-resolution digital camera. The data captured is analysed using 3D Laser Mapping’s SiteMonitor analysis software, which tracks and compares displacement measurements over time, providing early warning of abnormal movement and therefore potential failures in the active mining area Safety is always a key concern. Organisation and leadership are key elements of improving safety. However, new and improved technologies are constantly being developed in the battle against accidents and efforts to make them survivable. IM looks at some of the latest news from this area, showing where safety developments are having an impact on operational safety S tarting on the surface, the collapse of pit walls can be economic disasters and threats to personnel. Gold Fields has successfully implemented the latest laser scanning solution to help improve safety and increase production at the Damang gold mine in Ghana. The SiteMonitor system, developed and supplied by 3D Laser Mapping, combines state of the art laser scanning hardware with sophisticated software to capture and continuously analyse displacement measurements for the automatic monitoring of the mine’s pit walls. “During the trial phase the SiteMonitor system was used to scan several unstable areas across an entire pit wall,” explained Gordon Sweby, Principal Geotechnical Engineer. “Operating in continuous monitoring mode data was streamed to the geotechnical office via a wireless LAN. The next phase of the project will be to integrate the 40 International Mining DECEMBER 2008 system within mine operations realising the potential already identified and turning the system into an effective tool to aid safe mining.” On other pit slopes, Rio Tinto’s Rössing uranium mine, the biggest pit in Namibia, recently adopted GroundProbe’s SSR-X (Slope Stability Radar) for execution of critical slope monitoring at its operation. The SSR-X is the first slope stability monitoring radar ever deployed in Namibia having been on site since November 2007 for critical monitoring and evaluation. It is one of the most advanced slope monitoring radar technologies available, providing high resolution over long ranges. Samuel Banda, Geotechnical Superintendent at Rössing, said: “Obtaining reliable long range, high-resolution slope monitoring data is of critical importance for us to be able to ensure the safety of our operation and the SSR-X has proven itself following an extensive evaluation period”. SafetyWhips, a leading manufacturer of safety whips and whip lighting, recently introduced a robust Vehicle Display Identification System (VDIS) for use on haul trucks. This system provides a way of locating haul trucks, day or night, regardless of weather or dust conditions. The VDIS allows drivers to identify a moving vehicle in the most extreme conditions, through the use of LED lighting and solid state controls, that automatically adjust to the surrounding conditions. VDISs are available in different colours for a variety of environments, with them framed in metal housing and sealed against moisture. Through an integrated program, a VDIS unit can be immediately re-numbered and assigned to a different truck as needed with no need to keep a large stock of ‘numbers’ or other parts. For surface mine communications, Logimine showed version 4 of its Primary Command Center (PCC) at MINExpo 2008. The latest version has already been successfully installed at KATCO’s uranium mine in Kazakhstan. The PCC4 control software and on-board L2X series electronics enable real time tracking of any type of vehicle movement. It can also record time measurements, distances, breakdowns, availability and management of dispatch, loading, drilling and blasting activities. The unique capabilities of PCC4 include: ■ On-board displays with touch sensitive colour screen ■ Customisable architecture software ■ High-speed user interfaces ■ Automatic processing of data ■ Integration of high speed radio systems and HP GPS; UHV/VHF radio networks, TDMA and GPS metre or RTK centimetre tracking ■ Real-time Total Quality Management (TQM) with alert system; intercepted event can be stored in the database, monitored on a graph, or notified to manager (alert system). Logimine’s system is proven and very easy to use and maintain; it does not need a skilled engineer to support it. It uses IP communications to allow authorised users (secure ID access) to share and visualise all the cycle data collected; e.g. SAFE AND SOUND:proof 22/11/08 14:11 Page 2 MINE SAFETY start/end, time/date, travel distances, position, loading/unloading, shifts, equipment availability and utilisation. Display units with clear and friendly user interface are mounted on the dashboards to enable vehicle operators to rapidly communicate to managers information on any mechanical defects or malfunctioning equipment. For example, if they notice excessive gas or oil consumption, hydraulic leaks, defective tyres etc. Managers can then take immediate action to ensure safe operation e.g. by sending instructions to operators, adjusting shift cycles or altering vehicle routes and speeds to prevent collisions. Another advantage of the Logimine system is that it supports preventive maintenance. The system enables mechanics to manage mechanical subassemblies in real-time, and managers to immediately detect faults or safety issues such as a decrease of a vehicle speed or a sudden stop. “The PCC4 control system not only enables monitoring of all the production and ore quality in real-time from anywhere across the globe, it can also help mines to achieve zero accidents” comments Bruno Laforgue, Logimine Managing Director. “Since 2000, our close collaboration with Logimine has enabled us to go beyond the traditional mine site management and reach a higher level in terms of competitiveness. The complete Logimine system has enabled productivity optimisation and brought The Kidde Sentinel group of products, comprising the Sentinel Net and Sentinel SA-1 significant quality control and stockpile homogenisation improvements. We now have full control over our production. Logimine has been a superb investment!” says Julien Conté, Luzenac (Rio Tinto group), world leader in talc production. Underground lights The lamp is one of the most important tools that each underground miner carries. It is critical that this should not only provide sufficient light for the full duration of the working shift, but that it should also contribute toward the miner's safety rather than actually increasing the risks to which the miner is exposed. Whilst there are many lamps of varying price and quality, a few established names continue to represent the best in the class in terms of cost and safety, one of which is the Oldham lamp. The Umbrella of Mine Safety The mining industry is much safer today as a result of the use of high quality innovative products and systems. DSI Mining Products and Systems perfectly match today’s safety and quality requirements. Mechanical Rock Bolts Extension Bolts Stelpipe Bolts Our extensive R&D activities guarantee innovative and long-lasting strata reinforcement solutions. DSI is the global market leader in the development, production and application of ground support solutions for the mining industry. As a one-stop-shop provider, we are known as the umbrella of mine safety – always committed to your safety. Local Presence – Global Competence Rebar Rock Bolts Cable Bolts Friction Stabilizers & Expandable Bolts Trusses & Slings Fiberglass Bolts Headquarter Underground Asia/Pacific DYWIDAG-SYSTEMS INTERNATIONAL PTY. LTD. Bennetts Green, NSW 2290, Australia E-Mail: dsi@dywidag.com.au MINING SYSTEMS www.dsiminingproducts.com Headquarter Underground America DSI Ground Support Inc. Salt Lake City, UT 84104, USA E-Mail: dsimining@dsimining.com Resins & Cement Cartridges Mesh, Straps & Plate Washers Eyebolts, Scaling Bars & Utility Hangers Australia, Newcastle, NSW / Australia, Perth, WA / USA, Salt Lake City, UT / USA, Blairsville, PA / Mexico, Zapopan, Jalisco / Canada, Langley, BC Canada, Sudbury, ON / Canada, Saskatoon, SK / Canada, Rouyn-Noranda, PQ / Canada, Yellowknife, NT / Chile, Santiago de Chile / South Africa, Johannesburg Lattice Girders Steel Arches & Props High Performance Grouts Drilling Fluids Santiago de Chile CHILE Martinsburg USA Cambridge USA Bennetts Green AUSTRALIA DECEMBER 2008 International Mining 41 SAFE AND SOUND:proof 22/11/08 14:11 Page 3 MINE SAFETY Although the corporate name has changed to EnerSys, the Oldham branded caplamp remains synonymous with all high quality products throughout the world. The company says it has supplied “more lamps to more mines in more countries than any of its competitors in the whole history of ‘extra safety’ lamps.” Oldham has recently launched two new and significant products in the safety lamp range. Firstly, weighing just under 700 g, there is the new rugged L16 lithium-ion battery which is fully compatible with existing GT lamps, but offers advantages of light weight, ATEX certified battery design and suitability for 12-hour shift operations. The battery also has low self-discharge rates with no memory effect - outperforming every other battery technology currently available, the company claims. The L16 battery can be fitted with the conventional and proven G headpiece (twin halogen bulbs), or the second of Oldham's new products; the ATEX certified D headpiece using advanced LED technology. Use of a high power LED, running at a genuine 3 W, offers as much as 40% greater light output, or alternatively up to 30% reduction in battery usage; 10,000 hours LED life; shorter recharge time or longer shift operation; greatly reduced maintenance costs and a significant reduction of headpiece weight. All of its lamps, Oldham says “are fully repairable and can be shown over a normal fiveyear working life to be the most cost-effective system for personal lighting when compared with the lower cost units which have a four to 12 month life expectancy. Unfortunately though, some mines try to reduce initial purchase costs without understanding the consequential reduction in lamp performance or long-term costs. A low-cost lamp may fulfil the requirement for the miner to have a lamp, but if the miner can not see clearly, if the lamp only provides poor levels of illumination, then safety is being compromised. As a consequence, production levels (as well as other factors such as the miner’s sense of self-worth) can fall dramatically.” NL Technologies’ Northern Light® Eclipse cap lamps feature a four cell Lithium Ion battery and a 42 International Mining DECEMBER 2008 new style LED headpiece, which use a system of Total Internal Reflection (TIR™) to create maximum light output with minimum power draw. It offers a consistent lux of 2,000+ over a 12 hour shift. Koehler currently has MSHA approval on its entire product line. Its LI 5300 LED Wheat® cap lamp is, according to the company, “the smallest most powerful safety approved LED cap lamp on the market.” It comes certified with global safety ratings, lasts for 27 hours at a time without any deterioration in brightness, and has a recharging time of only six hours. It can operate in temperatures ranging from -20°C to 60°C and can be charged in temperatures ranging from 0 to 40°C. It also has a lamp life of 10,000 hours. Mica’s IL-60 EM, IL-80 ATEX EM and ML-800 ATEX EM lamps feature an emergency light operation, where in the occurrence of a power failure, the EM lamp lights up. It then automatically turns off when returned to the charger and/or power returns. These emergency lamps work between 7 to 24 hours and are entirely rechargeable. Mica EM lamps are used in places where high standard emergency lighting is needed. In addition to the emergency function, they can be used normally as effective flashlights. Advanced electronics control the halogen bulb/LED, protect the battery from deep discharge, and issue a low battery warning by intermittent bulb flashing. Forward planning Kidde Fire Systems introduced the first Factory Mutual approved aqueous suppression system for mobile machinery and vehicles at MinExpo Kidde Sentinel. This system can be designed to use the environmentally non-reportable wet agent, AquaGreenXT™, or a dry chemical agent, depending on application. It can also be configured with combinations of both wet and dry agent, providing primary and secondary protection to the machines. Sentinel is able to operate in a variety of temperatures ranging from extremes, such as artic mining or slag hauling, to milder climates. It is available in two forms, Kidde Sentinel Net, a network control system, and Kidde Sentinel SA-1 A 3D laser scan of a roadway extension could be useful for helping decide where improvements could be made to prevent accidents SAFE AND SOUND:proof 22/11/08 14:12 Page 4 MINE SAFETY The Dräger Alcotest 7510 enables monitoring of the alcohol levels of mine workers Results can then be transmitted to a connected printer or PC for verification. The large, high-contrast display makes it easy to read the menu, instructions and test results, even in poor light conditions. The instrument has a removable mouthpiece ensuring the user does not have to come into contact with saliva from the tested person. The Alcotest can be easily adapted to meet different international requirements and, depending on national legal regulations, can also be used in court proceedings. Users can determine the scope of documentation to suit specific needs. The optional GPS receiver can provide information on the exact location where the sample was collected in addition to the time and result of the measurement, with the results being visualised on maps. Data exchange is possible via USB or infrared interface to a PC. The use of lithium-ion batteries ensures a long operational life and means that the instrument can perform a high number of measurements. As well as determining breath alcohol concentrations in the workplace, it also allows: passive measurements without a mouthpiece, measurements of alcohol inside a vehicle and establishes if alcohol is present in liquids of unknown composition. IM Control Panel, a system without network capabilities. Nonetheless, both products are customisable for specific applications. Kate Houghton, Director of Marketing for Kidde, points at some key features of both systems: “[They] provide monitoring for up to two hours after the vehicle is shut down, but before complete cooling, when heat can build up and ignite fuels around the engine.” Both packages also include Wolfpack - a “global network of vehicle professionals [who provide] round-the-clock service.” Based on both infrared and heat detection, the systems detect and prevent fires from escalating inside a miners cab. They are designed for small to large size vehicles. Sentinel standard caters for small vehicles such as LHDs, Sentinel Advantage for mid size vehicles like dozers, and finally Sentinel Ultimate Net for the largest vehicles on the market such as big shovels and draglines. The systems can work in temperatures ranging from 37°C to 66°C allowing them to be used all over the world. DMT has developed an explosion-proof 3Dlaser-scanner for safety underground. It is particularly useful for monitoring underground roadway deformation e.g. roadway extension or undercutting of shafts. Until now, laser scanners could be used in both surface and underground mines, but not underground coal mines. This was because no scanners were available for use in potentially explosive atmospheres. Within a research and development project, DMT demonstrated the potential of the technology by carrying out different survey campaigns with commercial laser scanners, on approval by the Mining Authority. The success of these demonstration projects led to the development of the first explosion-proof laser scanner; the IMAGER 5006EX (based on the IMAGER 5006), which complies with ATEX regulations for mining zone 1. The main features of the IMAGER 5006EX technology are: ■ Contactless (remote) fully 3D measurement ■ Works in all lighting conditions (up to total darkness) ■ Adaptable – can be used in the majority of different natural and man-made surfaces ■ Additional registration of the reflectivity (like a grey scale picture) improvements could be made to prevent accidents. The first trial projects have shown great potential, with detailed and effective scans of many different underground operations. The company is hoping more trials such as these will highlight areas to improve, thus helping technicians develop what is already, a unique laser scanner. Sadly, substance abuse can still be a problem. The new Dräger Alcotest 7510 provides a clever and precise way of monitoring the alcohol levels of mine workers. It produces an accurate measurement of breath alcohol concentrations, even when residual mouth alcohol - a potentially misleading substance - may be present. This hand-held instrument can be used in temperatures from 10°C to + 50°C, delivering fast, definite measurements. Residual mouth The dawn of a new era with alcohol, which can be Lithium powered LED & Halogen ATEX / IEC lamps found when substances The new rugged L16 battery - compatible with existing containing alcohol have “G” lamps as well as the new “D” type LED headpiece. been consumed shortly Answering the call for: before a test, can potentially falsify results. Greater safety - ATEX and IEC Ex certified design; The Alcotest 7510 is Longer autonomy - 16Ah battery for 12-hour shifts; Lowest cost of life ownership – fully repairable. capable of detecting the presence of residual For more information, contact the EnerSys Mining team at: alcohol in the mouth, tel: +44 (0)161 727 3950 fax: +44 (0)161 727 3949 e-mail: hawker.mining@uk.enersys.com automatically alerting the ■ Very high accuracy (greater than 10 mm) ■ Huge measurement velocity (millions of points per minute). This system helps see weaknesses in an operating mine, helping decide where user. A simple, three-button menu operation guides the user through the entire sampling procedure. an EnerSys company DECEMBER 2008 International Mining 43