Tubes OTR Testing Report Summary

advertisement

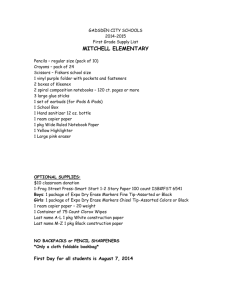

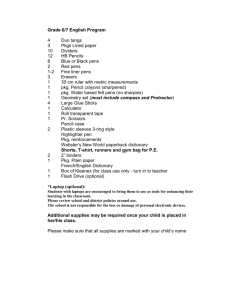

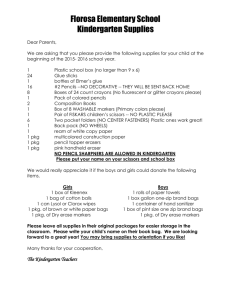

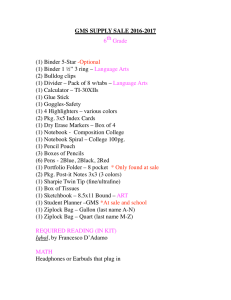

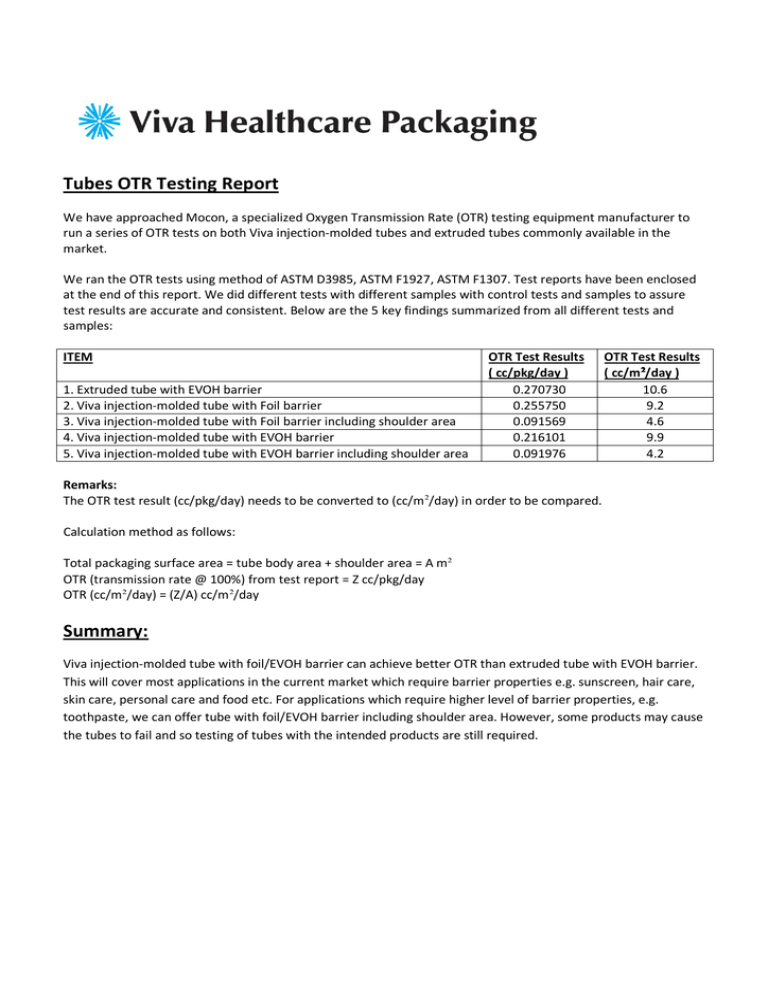

Tubes OTR Testing Report We have approached Mocon, a specialized Oxygen Transmission Rate (OTR) testing equipment manufacturer to run a series of OTR tests on both Viva injection-molded tubes and extruded tubes commonly available in the market. We ran the OTR tests using method of ASTM D3985, ASTM F1927, ASTM F1307. Test reports have been enclosed at the end of this report. We did different tests with different samples with control tests and samples to assure test results are accurate and consistent. Below are the 5 key findings summarized from all different tests and samples: ITEM 1. Extruded tube with EVOH barrier 2. Viva injection-molded tube with Foil barrier 3. Viva injection-molded tube with Foil barrier including shoulder area 4. Viva injection-molded tube with EVOH barrier 5. Viva injection-molded tube with EVOH barrier including shoulder area OTR Test Results ( cc/pkg/day ) 0.270730 0.255750 0.091569 0.216101 0.091976 OTR Test Results ( cc/m²/day ) 10.6 9.2 4.6 9.9 4.2 Remarks: The OTR test result (cc/pkg/day) needs to be converted to (cc/m²/day) in order to be compared. Calculation method as follows: Total packaging surface area = tube body area + shoulder area = A m² OTR (transmission rate @ 100%) from test report = Z cc/pkg/day OTR (cc/m²/day) = (Z/A) cc/m²/day Summary: Viva injection-molded tube with foil/EVOH barrier can achieve better OTR than extruded tube with EVOH barrier. This will cover most applications in the current market which require barrier properties e.g. sunscreen, hair care, skin care, personal care and food etc. For applications which require higher level of barrier properties, e.g. toothpaste, we can offer tube with foil/EVOH barrier including shoulder area. However, some products may cause the tubes to fail and so testing of tubes with the intended products are still required. MOCON OX-TRAN® 2/21 - Single Test Report Material Id: C3 Test Number: <D50 Extruded Tube with EVOH Barrier> Using Method: ASTMD3985, ASTMF1927,ASTMF1307 MODULE INFORMATION: CELL A INFORMATION: Module 1, Serial Number: Setup Name: Temp Setpoint/Actual: Barometric Pressure: Relative Humidity: MH_01761 Default Setup Auto: 23.0 / 23.0 °C. Manual: 760.00 mmHg Permeant - Auto: 65.0%, Carrier - Auto: 0.8% Permeant Concentration: Ambient Temp: 21 % Manual: 23.0 °C. TEST RESULTS Sample Type: Test Mode: Control Params: ExamMinutes: Individual Zero: Conditioning: Cycles Complete: Current Status: Started Testing: Elapsed Time: pkg: 0.4 mm Continuous Infinite 30 No Ind. Zero 5 Hours 6 Test Done 1/22/2011 8:38:04 AM 12:31 IN SELECTED UNITS Transmission @ 21 % Transmission @ 100% Permeation: DATA POINTS Time Rate/Event 0:00 Condition 9:00 0.278504 12:39 Complete 0.056853 0.270730 0.270730 Time 5:00 10:00 cc / [ pkg - day ] cc / [ pkg - day ] cc - mil / [ pkg - day ] Rate/Event Test 0.272031 Time 6:15 11:45 Rate/Event 0.381410 0.271307 Time 7:15 12:31 Rate/Event 0.331250 0.270730 Transmission Rate Data Graph 0.400 0.350 0.300 0.250 0.200 0.150 0.100 0.050 0.000 0.00 2.00 4.00 Printed on 1/22/2011 at 9:18:10 PM 6.00 8.00 10.00 Time (hrs) 12.00 14.00 16.00 18.00 20.00 Page 1 of 1 MOCON OX-TRAN® 2/21 - Single Test Report Material Id: <v16a> Test Number: <D50 Injection-molded Tube with Foil Barrier> Using Method: ASTMD3985, ASTMF1927,ASTMF1307 MODULE INFORMATION: CELL A INFORMATION: Module 1, Serial Number: Setup Name: Temp Setpoint/Actual: Barometric Pressure: Relative Humidity: MH_01761 Default Setup Auto: 23.0 / 23.1 °C. Auto: 737.37 mmHg Permeant - Auto: 63.4%, Carrier - Auto: 0.0% Permeant Concentration: Ambient Temp: 21 % Manual: 23.0 °C. TEST RESULTS Sample Type: Test Mode: Control Params: ExamMinutes: Individual Zero: Conditioning: Cycles Complete: Current Status: Started Testing: Elapsed Time: pkg: 0.4 mm Continuous Infinite 45 No Ind. Zero 5 Hours 7 Test Done 9/21/2011 5:18:57 PM 20:00 IN SELECTED UNITS Transmission @ 21 % Transmission @ 100% Permeation: DATA POINTS Time Rate/Event 0:00 Condition 11:00 0.254084 20:00 0.255750 0.053707 0.255750 0.102300 Time 5:00 13:15 21:16 cc / [ pkg - day ] cc / [ pkg - day ] cc - mm/ [ pkg - day ] Rate/Event Test 0.255499 Complete Time 6:30 15:30 Rate/Event 0.268904 0.257819 Time 8:45 17:45 Rate/Event 0.253837 0.255686 Transmission Rate Data Graph 0.400 0.350 0.300 0.250 0.200 0.150 0.100 0.050 0.000 0.00 2.00 4.00 Printed on 9/22/2011 at 2:35:42 PM 6.00 8.00 10.00 Time (hrs) 12.00 14.00 16.00 18.00 20.00 Page 1 of 1 MOCON OX-TRAN® 2/21 - Single Test Report Material Id: <V21a> Test Number: <D40 Injection-molded Tube with Foil Barrier & Shoulder> Using Method: ASTM D3985, ASTMF1927, ASTM F1307 MODULE INFORMATION: CELL A INFORMATION: Module 1, Serial Number: Setup Name: Temp Setpoint/Actual: Barometric Pressure: Relative Humidity: MH_01761 Default Setup Auto: 23.0 / 23.0 °C. Auto: 756.15 mmHg Permeant - Auto: 61.4%, Carrier - Auto: 0.0% Permeant Concentration: Ambient Temp: 20.9 % Manual: 23.0 °C. TEST RESULTS Sample Type: Test Mode: Control Params: ExamMinutes: Individual Zero: Conditioning: Cycles Complete: Current Status: Started Testing: Elapsed Time: pkg: 0.4 mm Continuous Infinite 45 No Ind. Zero 5 Hours 7 Test Done 11/29/2011 4:50:36 PM 17:45 IN SELECTED UNITS Transmission at 20.9% Transmission at 100% Permeation: DATA POINTS Time Rate/Event 0:00 Condition 10:15 0.092000 17:45 0.091569 0.019138 0.091569 0.036628 Time 5:00 11:45 18:48 cc / [ pkg - day ] cc / [ pkg - day ] cc - mm / [ pkg - day ] Rate/Event Test 0.091675 Complete Time 6:30 14:00 Rate/Event 0.098507 0.091297 Time 8:00 15:30 Rate/Event 0.094598 0.091541 Transmission Rate Data Graph 0.100 0.090 0.080 0.070 0.060 0.050 0.040 0.030 0.020 0.010 0.000 0.00 2.00 4.00 Printed on 11/30/2011 at 11:40:53 AM 6.00 8.00 10.00 Time (hrs) 12.00 14.00 16.00 18.00 20.00 Page 1 of 1 MOCON OX-TRAN® 2/21 - Single Test Report Material Id: <23b> Test Number: <D40 Injection-molded Tube with EVOH Barrier> Using Method: ASTM D 3985, ASTM F 1927, ASTM F 1307 MODULE INFORMATION: CELL B INFORMATION: Module 1, Serial Number: Setup Name: Temp Setpoint/Actual: Barometric Pressure: Relative Humidity: MH_01761 Default Setup Auto: 23.0 / 23.1 °C. Manual: 760.00 mmHg Permeant - Auto: 28.9%, Carrier - Auto: 0.7% Permeant Concentration: Ambient Temp: 21 % Manual: 23.0 °C. TEST RESULTS Sample Type: Test Mode: Control Params: ExamMinutes: Individual Zero: Conditioning: Cycles Complete: Current Status: Started Testing: Elapsed Time: pkg: 0.4 mm Continuous Infinite 30 No Ind. Zero Disabled 7 Test Done 12/27/2011 8:09:01 AM 8:00 IN SELECTED UNITS Transmission @ 21 % Transmission @ 100% Permeation: DATA POINTS Time Rate/Event 0:00 Test 4:30 0.217060 8:00 Complete 0.045381 0.216101 3.403171 Time 1:30 6:00 cc / [ pkg - day ] cc / [ pkg - day ] cc - mil / [ pkg - day ] Rate/Event 0.191019 0.216762 Time 2:30 7:00 Rate/Event 0.200941 0.216172 Time 3:30 8:00 Rate/Event 0.214988 0.216101 Transmission Rate Data Graph 0.300 0.250 0.200 0.150 0.100 0.050 0.000 0.00 1.00 2.00 Printed on 12/27/2011 at 4:09:45 PM 3.00 4.00 5.00 Time (hrs) 6.00 7.00 8.00 9.00 10.00 Page 1 of 1 MOCON OX-TRAN® 2/21 - Single Test Report Material Id: <24a> Test Number: <D40 Injection-molded Tube with EVOH Barrier & Shoulder> Using Method: ASTM D 3985, ASTM F 1927, ASTM F 1307 MODULE INFORMATION: CELL A INFORMATION: Module 1, Serial Number: Setup Name: Temp Setpoint/Actual: Barometric Pressure: Relative Humidity: MH_01761 Default Setup Auto: 23.0 / 23.0 °C. Manual: 760.00 mmHg Permeant - Auto: 26.0%, Carrier - Auto: 0.1% Permeant Concentration: Ambient Temp: 21 % Manual: 23.0 °C. TEST RESULTS Sample Type: Test Mode: Control Params: ExamMinutes: Individual Zero: Conditioning: Cycles Complete: Current Status: Started Testing: Elapsed Time: pkg: 0.4 mm Continuous Infinite 30 No Ind. Zero Disabled 7 Test Done 12/30/2011 8:01:36 AM 7:30 IN SELECTED UNITS Transmission @ 21 % Transmission @ 100% Permeation: DATA POINTS Time Rate/Event 0:00 Test 4:00 0.092998 8:11 Complete 0.019315 0.091976 1.448461 Time 1:00 5:30 cc / [ pkg - day ] cc / [ pkg - day ] cc - mil / [ pkg - day ] Rate/Event 0.081440 0.092020 Time 2:00 6:30 Rate/Event 0.092307 0.091160 Time 3:00 7:30 Rate/Event 0.093571 0.091976 Transmission Rate Data Graph 0.100 0.090 0.080 0.070 0.060 0.050 0.040 0.030 0.020 0.010 0.000 0.00 1.00 2.00 Printed on 12/30/2011 at 4:12:58 PM 3.00 4.00 5.00 Time (hrs) 6.00 7.00 8.00 9.00 10.00 Page 1 of 1