Direct Energy Conversion: Chemistry, Physics, Materials Science

advertisement

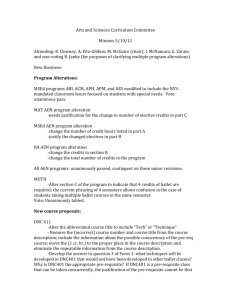

Direct Energy Conversion: Chemistry, Physics, Materials Science and Thermoelectrics Mercouri G Kanatzidis KANATZIDIS KANATZIDIS MSU,CHEMISTRY CHEMISTRY MSU, SolidState StateChemistry Chemistry Solid Synthesis,Discovery Discovery Synthesis, S. D. MAHANTI MSU, PHYSICS Theory TIM HOGAN MSU, E. ENGINEERING Measurements, Devices CTIRAD CTIRAD UHER UHER Univ Univ of of Michigan Michigan Physics Physics Measurements Measurements American Physical Society Meeting, Baltimore March 2006 MURI HAROLD SCHOCK MSU, Mechanical Engineering Applications ELDON CASE MSU, Mechanical Engineering Metallurgy Heat to Electrical Energy Directly Up to 20% conversion efficiency with right materials http://www.dts-generator.com/ Schock group Thermoelectric applications Waste heat recovery • Automobiles • Over the road trucks • Utilities • Chemical plants Space power Remote Power Generation Solar energy Geothermal power generation Direct nuclear to electrical U.S. Energy Flow, 1999 web site: www.eia.doe.gov Given that ~60% of energy becomes waste heat, even a 10% capture and conversion to useful forms can have huge impact on overall energy utilization How does it work? http://www.designinsite.dk TE devices have no moving parts, no noise, reliable Figure of Merit 0.25 δ = 0.0 δ = 0.1 0.2 electrical conductivity 0.15 σ⋅S ZT = •T κ total δ = 1.1 η 2 0.1 0.05 Total thermal conductivity 0 0 0.5 1 1.5 ZT 2 2.5 3 avg δ=Rc/R thermopower For Th = 800K Tc = 300K Power factor σ⋅S 2 Today’s situation The most efficient materials today for power generation: PbTe and TAGS (TeSbGeAg alloy) The most efficient material for cooling Bi2Te3 Quantum Dot Layers in thin MBE-grown PbSe/PbTe PbTe: ZT~0.8 at 800 K (n-type) superlattices (Harman et al, TAGS: ZT~1.2 700 K (p-type) ZT~3) Bi2Te3-xSex: ZT~1 at 300 K Further improvements are needed. PbTe New materials needed PbSe 20 nm dot Hicks LD, Dresselhaus MS Phys. Rev. B 47 1993 (24): 16631 Some promising systems under investigation half-Heusler alloys (ZrNiSn) Zn4Sb3 Clathrates Skutterudites (CoSb3) Bulk nanocomposites based on PbTe Bulk nanocomposites based on Si-Ge AgSbTe2/PbTe, NaSbTe2/PbTe See March 2006 issue of MRS Bulletin ZT and Electronic Structure Isotropic structure Anisotropic structure mx m y T τ mz 3/ 2 Z max ∝γ e κ latt m= effective mass τ=scattering time r= scattering parameter κlatt= lattice thermal conductivity T = temperature (r +1/ 2 ) For acoustic phonon scattering r=-1/2 E E γ= band degeneracy Large γ comes with (a) high symmetry e.g. rhombohedral, cubic (b) off-center band extrema Ef k k k Complex electronic structure Selection criteria for candidate materials Narrow band-gap semiconductors Heavy elements High µ, low κ Large unit cell, complex structure low κ Highly anisotropic or highly symmetric… Complex compositions low κ, complex electronic structure Chemistry as a source of materials Investigating the System: A2Q + PbQ + M2Q3 –––––> (A2Q)n(PbQ)m(M2Q3)p Map generates target compounds Cubic materials ABmMQ2+m A=Ag, K, Rb, Cs M=Sb, Bi Q=Se, Te A2 Q Phases shown are promising new TE Materials Rb0.5Bi1.83Te3 APb2Bi3Te7 A1+xPb4-2xBi7+xSe15 PbQ Pb6Bi2Se9 Pb5Bi6Se14 Pb5Bi12Se23 β-K2Bi8Se13 CsBi4Te6 Bi2Q3 Our first contact with cubic AgPbmSbTe2+m AgBi3S5, KPbBi9Se13, KPb4Sb7Se15 CsPbBi3Te6, CsPb2Bi3Te7, CsPb3Bi3Te8, RbPbBi3Te6, RbPb2Bi3Te7, RbPb3Bi3Te8, KPbBiSe3, K2PbBi2Se5 K2Pb3Bi2Te7, KPb4SbTe6 AgPbmSbTe2+m (LAST-m) AgPbm(Sb,Bi)Te2+m (BLAST-m) Pb Te Sb Ag Unit cell volume (Å) 268 267 266 265 264 Vegard's law 263 6 8 10 12 14 16 18 m value (1) (a) Rodot, H. Compt. Rend. 1959, 249, 1872-4. (2) (a) Rosi, F. D.; Hockings, E. S.; Lindenblad, N. E. Adv. Energy Convers. 1961, 1, 151. (LAST-18) Ag1-xPb18SbTe20: Tunable properties Changing x 0.8 Comparison of Thermopower 0.7 Ag0.73 (KF2207R2b) Ag0.76 (KF2228R3A2) Ag0.78 (KF2213R1B) Ag0.80 (KF2213R2C) Ag0.82 (KF2229R1A) Ag0.82 (KF2229R1B) Ag0.82 (KF2229R1C) Ag0.82 (KF2229R1D) -50 -100 0.6 0.5 ZT Thermopower (µ V/K) 0 -150 Comparison of ZT Ag0.73 (KF2207R2b) Ag0.76 (KF2228R3A2) Ag0.78 (KF2213R1B) Ag0.80 (KF2213R2C) Ag0.82 (KF2229R1A) Ag0.82 (KF2229R1B) Ag0.82 (KF2229R1C) Ag0.82 (KF2229R1D) 0.4 0.3 0.2 -200 0.1 -250 50 100 150 200 250 300 350 400 450 Temperature (K) 30 2 2 Power Factor S σ (µW/cm K ) Ag0.73 (KF2207R2b) Ag0.76 (KF2228R3A2) Ag0.78 (KF2213R1B) Ag0.80 (KF2213R2C) Ag0.82 (KF2229R1A) Ag0.82 (KF2229R1B) Ag0.82 (KF2229R1C) Ag0.82 (KF2229R1D) 20 10 0 50 100 150 200 250 300 Temperature (K) 120 160 200 240 280 320 360 400 Temperature, K Comparison of Power Factors 50 40 0 80 350 400 450 Synthesis: Heating cooling profiles rock T, K 950-1000 ºC Cool to 50 ºC in 72 h 13 deg/h Ingot properties very sensitive to cooling profile Gravity induced inhomogeneity LAST-18 time, h 1000 ºC rock T, K Cool to 50 ºC in 24 h time, h Wernick, J. H.. Metallurg. Soc. Conf. Proc. (1960), 5 69-87. R. G. Maier Z. Metallkunde 1963, 311 Strongly varying composition from top to bottom. Strongly varying properties from top to bottom. “Sweet” spot exists with very high ZT. Mechanical properties weak. m= 8 m= 14 m= 18 σ (S/cm) S (µV/K) Samples cooled slowly from liquid to solid m= 25 m= 40 Strong composition grading along ingot Properties of Ag1-xPb18SbTe20 2.5 2000 Lattice thermal conductivity -150 1500 -250 1000 -300 500 -350 0 300 -400 350 400 450 500 550 600 650 S (µV/K) σ (S/cm) -200 Lattice Thermal Conductivity (W/mK) -100 2 PbTe 1.5 1 LAST-18 0.5 0.35 W/mK (Harman PbTe/PbSe superlattice) 700 0 Temperature, K 300 400 500 600 Temperature (K) 700 800 Ag1-xPb18SbTe20 2.00 Ag Pb SbTe 0.86 18 20 ZT 1.50 1.00 0.50 0.00 300 350 400 450 500 550 600 650 700 Temperature, K Hsu KF, Loo S, Guo F, Chen W, Dyck JS, Uher C, Hogan T, Polychroniadis EK, Kanatzidis MG Science, 2004, 303, 818 What is the origin of the TE properties of AgPbmSbTem+2 systems? HRTEM Coherently embedded nanocrystals Pb- rich region 8-10 nm Ag-Sb rich region Polychroniadis, Frangis, 2004 LAST-18 κlatt=1.2 W/m-K at 300 K PbTe κlatt=2.2 W/m-K at 300 K Coherent compositional fluctuations in AgPbmSbTem+2 FCC lattice 10 nm Ag, Sb, Pb ordering Driving force for segregation Ag+/Sb3+ pair: stable Ag Te Te Pb Te Pb Pb Te Pb Te Ag Pb Te Te Pb Pb Te Pb Pb Te Te Sb Te Te Pb Te Pb Te Pb Te Pb Pb Te Sb Te Pb Te Pb Te Te Ag Pb Te Sb Te Pb Pb Te Te Te Te Te Pb Pb Te Pb Dissociated state..unstable Pb Pb Te Pb Te Pb Te Te Pb Te Pb Te Ag Te Pb Te Sb Te Pb Te Pb Te Te Pb Pb Te Pb Associated state..stable Any +1/+3 pair Te Solid solutions in (AgSbTe2)1-x(PbTe)x LAST-m 0 20 40 60 80 100 Thermal Conductivity(mW/cm·K) (W/cmK) LatticeLattice Thermal Conductivity 20 Klemmens-Drabble theory 18 m=65 16 14 m=62 m~62 12 Random alloy m~30 10 m=18 8 m=10 6 Experimental Points below theoretical 4 0 AgSbTe2 m=18 20 T. Irie Jap. J. Appl. Phys. 1966, 5, 854 40 60 Mol % PbTe 80 100 PbTe P-type materials, LASTT 1000 12000 Ag0.3Pb7Sn3Sb0.1Te12 10000 8000 6000 4000 2000 0 20 30 40 50 60 2Theta 70 80 90 100 2 hours rocking 800 o Temperature ( C) (LASTT-m) Ag(Pb1-xSnx)mSbTe2+m Sn atoms act as acceptors Ag atoms act as acceptors Sb atoms act as donors e.g AgPb10Sn8SbTe20, AgxPb7Sn3SbyTe12, Very low lattice thermal conductivity Good homogeneity Intensity (arb. units) 600 400 200 0 0 10 20 30 t (hours) 40 50 60 LASTT-16 Very low lattice thermal conductivity κlatt =0.5 W/m·K at 650 K Androulakis, Hsu, Hogan, Uher, Kanatzidis Advanced Mater. 2006, in press LASTT-16: AgPb12Sn4Sb0.4Te20 320 280 Seebeck (uV/K) 240 200 160 120 80 40 0 320 400 480 560 T e m p e ra tu re , K 640 720 Androulakis, Hsu, Hogan, Uher, Kanatzidis Advanced Mater. 2006, in press Figure of Merit LASTT (p-type) 2.0 1.8 Ag0.5 Pb6 Sn2 Sb0.2 Te10 1.6 Ag0.9 Pb5 Sn3 Sb0.7 Te10 (b) Ag0.6 Pb7 Sn3 Sb0.2 Te12 1.4 LASTT ZT 1.2 TAGS 1.0 0.8 0.6 PbTe 0.4 0.2 0.0 300 400 500 600 700 800 Temperature (K) Androulakis, Hsu, Hogan, Uher, Kanatzidis Advanced Mater. 2006, in press (A) Lattice Thermal conductivity (W/mK) NaPb20SbTe22 (SALT-20) 2 (B) 1.5 1 0.5 0 Pb Sn Te 0.9 0.1 not-nano PbTe Se 0.9 0.1 Na Pb SbTe 1-x 20 22 nano 300 350 400 450 500 550 600 650 700 Temperature, K 50 nm Poudeu, Hogan, Kanatzidis Angew. Chemie, 2006, SALT-20 Poudeu, Hogan, Kanatzidis Angew. Chemie, 2006, State of the art - bulk 2.5 2 LAST NaPb SbTe 20 22 LASTT 1.5 ZT TAGS Tl BiTe 9 1 CsBi Te 4 6 6 Ce Fe CoSb Bi Te 2 0.9 3 3 12 SiGe PbTe 0.5 0 0 200 400 600 800 Temperature, K 1000 1200 1400 Conclusions New approaches are succeeding in raising ZT The (A2Q)n(PbQ)m(Bi2Q3)p (Q=Se, Te) system is a rich source of new materials Several new promising compounds identified LAST, LASTT and SALT family of materials strongly anisotropic cubic nanostructured nanostructured superior ZT Strong thermal conductivity reduction achieved through nanostructuring Doping studies and processing conditions are important in ZT optimization Outlook Further progress is expected on the TE figure of merit Fundamental challenge: • • Research in new materials should focus on • • • Translate current theoretical physical predictions on how to enhance Power Factor (σ·S2) into actual chemistry in the laboratory Achieve minimum thermal conductivity (~0.3 W/mK) in a bulk (nano)crystalline TE material Understanding and controlling carrier scattering Controlling nanostructuring to manipulate phonon propagation Discovering new compounds Long term: Waste heat recovery and conversion could be impacted on a massive scale with low cost materials if ZT>2-3. Thermoelectrics could help utilize existing depletable energy resources more effectively Thermoelectrics could also play role in renewable energy (e.g. solar, etc) Collaborators Tim Hogan, Dept of Electrical Engineering, MSU S. D. (Bhanu) Mahanti, Dept. of Physics, MSU Ctirad Uher, Dept. of Physics, U of Michigan Simon Billinge, Physics, MSU Eldon Case, MSU Harold Schock, MSU Bruce Cook, Iowa State Terry Tritt, Clemson U Art Schultz, Argonne NL TE Research group Dr Duck young Chung Joseph Sootsman Dr Kuei fang Hsu Dr Eric Quarez Aurelie Guegen Ferdinand Poudeu Jun-Ho Kim Dr John Androulakis