Saturday, June 11, 2005

advertisement

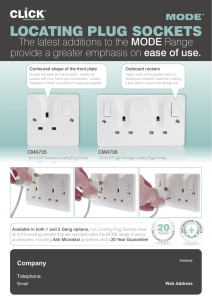

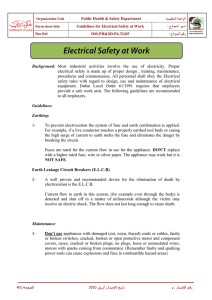

Office of Health and Safety Reg. No. 200604393R Ref : NTU/0HS/ALERT/01.0 Title : ELECTRICAL FIRES Date of issue : 27 November 2008 Issued by : Office of Health and Safety Audience : All Staff and Students ELECTRICAL FIRES The Incident There was an incident on 21 Nov 2008. A smouldering fire broke out from an electrical socket connected to a machine in one of the laboratories. The staff noticed this and quickly shut down the machine and switched off the power. This averted a possible major incident. The small fire burnt itself out. Fortunately there were no highly flammable liquids or combustible material near the plug to fuel the smouldering fire. No one was injured. There is no substantial material damage to property; the machine is being shut down pending investigation. It had been reported there were several electrical trips before the fire; but each time the MCB was reset and normal operations continued. The power plug of this machine was connected to an extension cable (4 gang 3-pin portable socket-outlet). A typical socket outlet is shown as Picture A. The rated power for the machine is 15A. Picture A 4 gang 3-pin portable socket-outlet. 1 As the machine would be working round the clock, the plug was also connected to a socket protector to prevent sudden current overloading (Picture B). Picture B Socket Protector used in the laboratory. After the fire, the plug was taken apart and the seat of the fire was the connection of the live wire and the 13A replaceable fuse (Picture C). Picture C Possible causes: 1) If a fault develops, the current (and heat energy) can increase significantly to the extent that the appliance burns out or the connecting wiring overheats and melts the plastic insulation or the plug and socket may burn out. 2) The fault could be due to faulty equipment, poor connection, damaged wires, highly oxidized plug contact or wet contact surfaces. What must we do? 1. DO NOT use extension sockets as permanent wiring, especially in laboratories, workshops and canteens. Extension sockets are not to be used outdoors. 2. Use extension sockets for low current appliances; the total rated current for such extension should NOT exceed 13A (A is ampere, a unit of current). 3. DO NOT use extension sockets if the rated current of the appliance is more than 13A. 4. Check the equipment and appliance regularly by service agents. If the equipment had not been used for some time, have them checked before using. 5. Conduct regular safety inspection of work area and office to include sockets, connecting wires and extension sockets. 6. Check appliance and equipment (including connecting wires) if there are frequent electrical trips; do not turn on the appliance until it has been checked. 7. Maintain good housekeeping. Keep all combustible and flammable materials well away from all electrical outlets and connections. 8. Do not attempt to repair any sockets and appliance unless you are trained. Electrical works must be done by a licensed electrical worker. 2 9. SWITCH off any equipment and appliance when not in use, preferably at the socket. This should be done at the end of the working day. Avoid putting equipment on ‘stand by’ or ‘on’ mode. 10. Ensure all appliances used had been tested to an internationally acceptable safety standard. In Singapore, all plugs, sockets and some common electrical items MUST bear the Safety Mark (Picture D). Picture D 11. Never pull out a plug when the current is still flowing. Switch it off first. 3