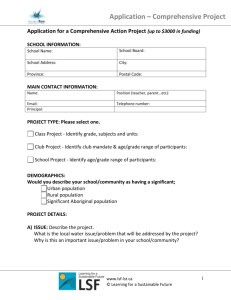

Gyproc Metal components

Metal components

224 www.gyproc.ae

Gypframe metal components

Gypframe metal stands for quality, strength and durability through a range of components that provide the backbone for our tested and warranted wall, ceiling, lining and encasement systems.

The unique manufacturing process, including the patented

UltraSteel™ double helix work hardening process, means that Gypframe metal components are:

• Precision engineered for premium quality

• Lighter to carry and handle

• Easier to cut and fit

• Rigidised for extra strength

• Allow enhanced screw fixing and retention

• The only metal components to carry the

• SpecSure system performance warranty when

installed in our proprietary systems

Benefits of Gypframe:

• Galvanised steel that will not warp or rust

• Easy to cut on site, saving time and creating no mess

• Limited waste - any off-cuts can be recycled

• Self locking studs and channels, that are quick to install

• Improved screw retention and strip out strength

• Improved resistance to screw pull-out

• Lightweight – easy to move around site and build to greater height

Manufacturing Standards:

All Gypframe components are rigourously tested to internationally recognised product standards and conform to.

• British Standard BS 7364

• European Standard EN 14195

• American Standard ASTM C645

Gypframe studs

‘C’ Studs

‘I’ Studs

Metal components index

227

227

Gypframe channels

Standard Channels

Deep Channels

Extra Deep Channels

MF

Ceiling Channels

Fixing Channels

Gypframe Stud & Accessories

ShaftWall Starter & Retaining Channels

Gypframe Angles

228

228

229

229

227

227

228

228 www.gyproc.ae

225

Bespoke Gypframe Gypframe reference codes and abbreviations

Gyproc offers a comprehensive bespoke service for the

Gyproc plasterboard and Gypframe metal product ranges.

Whether you require a non-standard length, alternative gauge or other specification change, we’ll try to provide you with the best solution for your project. Specifying bespoke metal lengths can speed up construction as there is no need to trim them to the correct length, and will save waste on site, helping with site safety and cost reduction.

For more information contact the customer service centre on

+971 800 GYPROC (497762)

To understand a Gypframe metal product, follow these simple steps:

Step 1

The first 2 or 3 digits refer to the component width

Step 2

The letter refers to the product type i.e.,

S = Stud, C = Channel

Step 3

The last two digits indicate the metal thickness or gauge in mm i.e., 0.50mm

See example below

Key

I

S

C

DC

EDC

RC

SC

MF5

MF7

GA1

GL1

FC

Component width in mm

Example = 70mm

70 I 70

Component type

Example = 'I' Stud

Gypframe Component

‘C’ Stud

‘I’ Stud

Channel

Deep Channel

Extra Deep Channel

Retaining Channel

Starter Channel

Furring Channel

Main Channel

Wall Angle

GypLyner Channel

Fixing Channel

Stud gauge

Example = 0.70mm

Flange Dimension

32mm / 34mm

38mm

25mm

50mm

70mm

15mm

30mm

69mm x 22mm

38mm x 12.5mm

25mm x 25mm

38mm x 12.5mm

103/153 x 9mm

226

www.gyproc.ae

Gypframe studs and channels

Gypframe ‘C’ Studs Gypframe ‘I’ Studs

Product Characteristics

Used as the vertical support in wall framing. A range of widths, lengths and thicknesses depending on requirements for strength, height, impact resistance and sound insulation.

Manufactured using patented, UltraSteel™ technology giving a rigidised surface for additional strength. Service cut-outs are also placed along the spine of Gypframe ‘C’ Studs providing easy routing of services through the partition.

Product Characteristics

These studs are the strongest available in the Gypframe range. They allow for increased partition height, without increasing the partition width, and provide improved impact resistance. Commonly used in ShaftWall, Gyplyner IWL,

GypWall QUIET IWL and other GypWall systems. Service cut-outs are also spaced along the spine of the Gypframe ‘I’

Stud, providing easy routing of services through a partition.

Product Matrix

Component^

50 S 50

63 S 50

70 S 50

73 S 50

92 S 50

100 S 50

150 S 50

Length (mm)*

3000

3000

3000

3000

3000

3000

3000

^ - Also available in 0.6, 0.7, 0.8 and 0.9 thickness

* - Bespoke lengths available on request

Product Matrix

Component

70 I 70

100 I 80

150 I 90

* - Bespoke lengths available on request

Length (mm)*

3000

3000

3000

Gypframe Standard Channels Gypframe Deep Channels

Product Characteristics

Gypframe channels are used for securing Gypframe ‘C’ Studs at floor and ceiling junctions. Gypframe Channels (C) are used for partition heights of up to 4200mm and are manufactured using the patented UltraSteel™ process giving a rigidised surface for better screw holding and increased tensile strength.

Product Characteristics

Gypframe channels are used for securing Gypframe ‘C’ Studs at floor and ceiling junctions. Gypframe Deep Channels (DC) are used for partition heights between 4200mm and

8000mm or in situations where deflection heads or improved impact resistance are required. Deep Channels are manufactured using the patented UltraSteel™ process giving a rigidised surface for better screw holding and increased tensile strength.

Product Matrix

Component^

52 C 50

65 C 50

72 C 50

75 C 50

94 C 50

102 C 50

152 C 50

Length (mm)*

3000

3000

3000

3000

3000

3000

3000

^ - Also available in 0.6, 0.7, 0.8 and 0.9 thickness

* - Bespoke lengths available on request

Product Matrix

Component^

52 DC 60

65 DC 60

72 DC 60

75 DC 60

94 DC 60

102 DC 60

152 DC 60

^ - Also available in 0.7, 0.8 and 0.9 thickness

* - Bespoke lengths available on request

Length (mm)*

3000

3000

3000

3000

3000

3000

3000 www.gyproc.ae

227

228

Gypframe studs, channels and accessories

Gypframe Extra Deep Channels

Gypframe

MF

Ceiling Channels and accessories

Product Characteristics

Gypframe channels are used for securing Gypframe ‘C’ Stud at floor and ceiling junctions. Gypframe Extra Deep Channels

(EDC) are used for partition heights over 8000mm or in situations where deflection head details or improved impact resistance is required. Extra Deep Channels are manufactured using the patented UltraSteel™ process giving a rigidised surface for better screw holding and increased tensile strength.

Product Characteristics

Gypframe MF Ceiling Channels are used for providing a robust false ceiling system. These sections are manufactured using the patented UltraSteel™ process giving a rigidised surface for better screw holding and increased tensile strength.

Product Matrix

Component Thickness (mm)^ Length (mm)*

Product Matrix

Component^

52 EDC 80

65 EDC 80

72 EDC 80

75 EDC 80

94 EDC 80

102 EDC 80

152 EDC 80

^ - Also available in 0.9 thickness

* - Bespoke lengths available on request

Length (mm)*

3000

3000

3000

3000

3000

3000

3000

MF5 (Furring) Section

MF7 (Furring) Channel

Soffit Cleat with Nut & Bolt

0.5

0.5

-

3000

3000

Box

^ - Also available in 0.6, 0.7, 0.8 and 0.9 thickness,

MF7 is also available in 1.5 thickness.

* - Bespoke lengths available on request

Gypframe Channels Gypframe Stud and accessories

Product Characteristics

Used to maintain board fixings along horizontal joints in multi-layer boarded systems and to give added support for fixtures and fittings.

Product Characteristics

These components are designed to aid the installation of plasterboard linings directly to concrete and blockwork walls.

They are manufactured using the patented UltraSteel™ process giving a rigidised surface for better screw holding and increased tensile strength.

Product Matrix

Component

Fixing Channels

103 FC 50

103 FC 90

153 FC 90

Thickness (mm)^ Length (mm)*

0.5

0.9

0.9

Service Support Plate -

* - Bespoke lengths available on request

2400

2400

2400

92

Product Matrix

Component Thickness (mm)^ Length (mm)*

GL1 Stud 0.5

GLB85 Bracket -

GLB135 Bracket -

^ - Also available in 0.6, 0.7 and 0.8 thickness

* - Bespoke lengths available on request

3000

Box

Box

www.gyproc.ae

Gypframe channels and angles

ShaftWall Channels Gypframe Angles

Product Characteristics

These products are used for the high performance

ShaftWall system used to create lift shaft and service riser linings that can be constructed from one side and provide structural and fire protection applications.

Product Characteristics

Gypframe steel angles are widely used in framed construction to provide support, protection, fixing and additional strength to wall, ceiling and encasement framing.

Product Matrix

Component

Starter Channels

70 SC 70

100 SC 80

150 SC 90

Retaining Channels

RC 70

RC 100

RC 150

* - Bespoke lengths available on request

Length (mm)*

3000

3000

3000

3000

3000

3000

Product Matrix

Component Thickness (mm) Length (mm)

GA1 Angle

(Floor and Ceiling Angle)

GA3 CoreBoard Joint Angle

0.5

*

0.7

3000

3000

GA4 Angle 0.7

3000

GA6 Splayed Angle 0.5

3000

* - GA1 Angle is also available in 0.6, 0.7, 0.8, 0.9 and 1.5mm

thickness www.gyproc.ae

229