Ballistic Penetration Response Of Glass Fibre Reinforced Polyester

advertisement

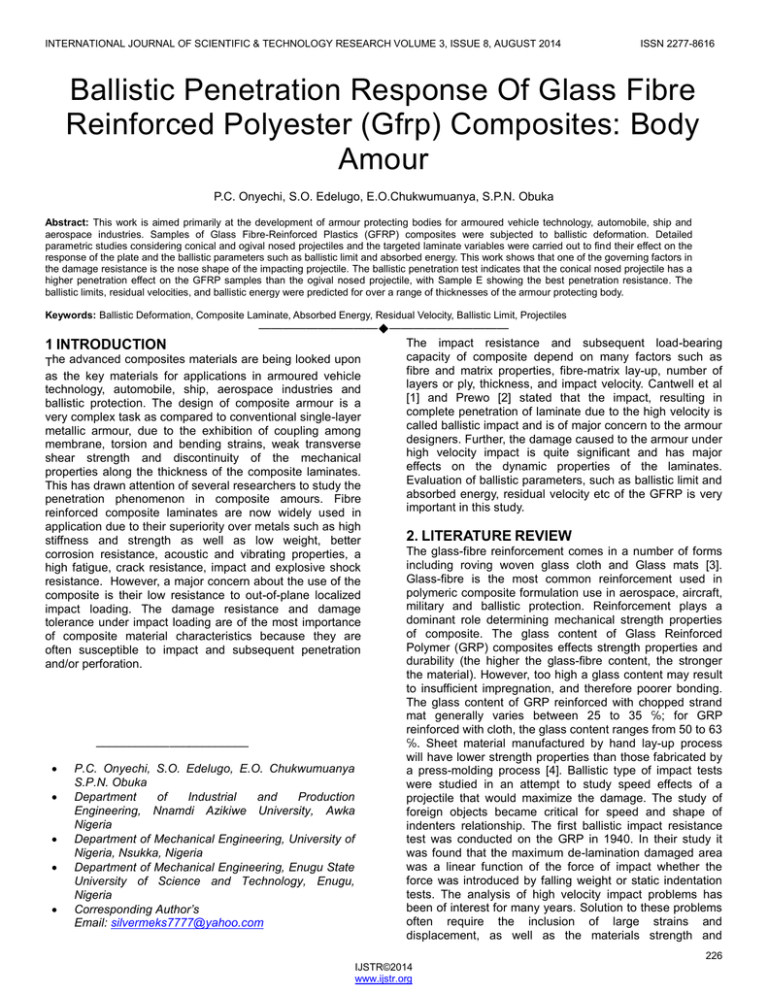

INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 ISSN 2277-8616 Ballistic Penetration Response Of Glass Fibre Reinforced Polyester (Gfrp) Composites: Body Amour P.C. Onyechi, S.O. Edelugo, E.O.Chukwumuanya, S.P.N. Obuka Abstract: This work is aimed primarily at the development of armour protecting bodies for armoured vehicle technology, automobile, ship and aerospace industries. Samples of Glass Fibre-Reinforced Plastics (GFRP) composites were subjected to ballistic deformation. Detailed parametric studies considering conical and ogival nosed projectiles and the targeted laminate variables were carried out to find their effect on the response of the plate and the ballistic parameters such as ballistic limit and absorbed energy. This work shows that one of the governing factors in the damage resistance is the nose shape of the impacting projectile. The ballistic penetration test indicates that the conical nosed projectile has a higher penetration effect on the GFRP samples than the ogival nosed projectile, with Sample E showing the best penetration resistance. The ballistic limits, residual velocities, and ballistic energy were predicted for over a range of thicknesses of the armour protecting body. Keywords: Ballistic Deformation, Composite Laminate, Absorbed Energy, Residual Velocity, Ballistic Limit, Projectiles ———————————————————— The impact resistance and subsequent load-bearing capacity of composite depend on many factors such as The advanced composites materials are being looked upon fibre and matrix properties, fibre-matrix lay-up, number of as the key materials for applications in armoured vehicle layers or ply, thickness, and impact velocity. Cantwell et al technology, automobile, ship, aerospace industries and [1] and Prewo [2] stated that the impact, resulting in ballistic protection. The design of composite armour is a complete penetration of laminate due to the high velocity is very complex task as compared to conventional single-layer called ballistic impact and is of major concern to the armour metallic armour, due to the exhibition of coupling among designers. Further, the damage caused to the armour under membrane, torsion and bending strains, weak transverse high velocity impact is quite significant and has major shear strength and discontinuity of the mechanical effects on the dynamic properties of the laminates. properties along the thickness of the composite laminates. Evaluation of ballistic parameters, such as ballistic limit and This has drawn attention of several researchers to study the absorbed energy, residual velocity etc of the GFRP is very penetration phenomenon in composite amours. Fibre important in this study. reinforced composite laminates are now widely used in application due to their superiority over metals such as high 2. LITERATURE REVIEW stiffness and strength as well as low weight, better The glass-fibre reinforcement comes in a number of forms corrosion resistance, acoustic and vibrating properties, a including roving woven glass cloth and Glass mats [3]. high fatigue, crack resistance, impact and explosive shock Glass-fibre is the most common reinforcement used in resistance. However, a major concern about the use of the polymeric composite formulation use in aerospace, aircraft, composite is their low resistance to out-of-plane localized military and ballistic protection. Reinforcement plays a impact loading. The damage resistance and damage dominant role determining mechanical strength properties tolerance under impact loading are of the most importance of composite. The glass content of Glass Reinforced of composite material characteristics because they are Polymer (GRP) composites effects strength properties and often susceptible to impact and subsequent penetration durability (the higher the glass-fibre content, the stronger and/or perforation. the material). However, too high a glass content may result to insufficient impregnation, and therefore poorer bonding. The glass content of GRP reinforced with chopped strand mat generally varies between 25 to 35 ℅; for GRP reinforced with cloth, the glass content ranges from 50 to 63 _______________________ ℅. Sheet material manufactured by hand lay-up process will have lower strength properties than those fabricated by P.C. Onyechi, S.O. Edelugo, E.O. Chukwumuanya a press-molding process [4]. Ballistic type of impact tests S.P.N. Obuka were studied in an attempt to study speed effects of a Department of Industrial and Production projectile that would maximize the damage. The study of Engineering, Nnamdi Azikiwe University, Awka foreign objects became critical for speed and shape of Nigeria indenters relationship. The first ballistic impact resistance Department of Mechanical Engineering, University of test was conducted on the GRP in 1940. In their study it Nigeria, Nsukka, Nigeria was found that the maximum de-lamination damaged area was a linear function of the force of impact whether the Department of Mechanical Engineering, Enugu State force was introduced by falling weight or static indentation University of Science and Technology, Enugu, tests. The analysis of high velocity impact problems has Nigeria been of interest for many years. Solution to these problems Corresponding Author’s often require the inclusion of large strains and Email: silvermeks7777@yahoo.com displacement, as well as the materials strength and 1 INTRODUCTION 226 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 compressibility effects, the analysis techniques are complicated and large computer codes are necessary to obtain these solutions. The earlier solutions of high velocity impact problems were often obtained with two-dimensional Lagrangian codes such as HEMP of [5] and TOODY II by [6]. Two-dimensional Eulerian codes such as HELP program by [7] were later applied to these problems. A three-dimensional version of HEMP has also been developed [8]. The finite-element method has recently been applied to two-dimensional impact problems involving severe distortion [9]. Various theories proposed for predicting the characteristics of penetration of composite laminates by different projectiles have been reviewed by [10, 11]. Ductile composite materials, such as laminates reinforced by aramids or polyethylene fibres, have been studied by [12, 13, and 14]. They proposed both experimental and analytical models to predict the perforation and the ballistic limit for Kevlar/epoxy laminated composite by conical projectiles, considering local and global deformations. Vinoson and Walker [15] developed a conical shell model and solve the perforation problem using the finite-difference technique. Sun and Potti [16] developed a simple ring model for a cylindrical im16pactor which was then solved numerically to predict residual velocities. These models tend to be specific to the composite configurations tested. Abrate [10] reviewed a large number of papers on ballistic impact and he focused his discussion on predictive models for the ballistic limits. High velocity projectiles owe their destructive penetrating ability to the kinetic energy they carry with them. Conversely, the efficacy of any material resisting such kinetic energy projectiles depends on its ability to absorb the kinetic energy. The energy absorption capacity in turn depends on target material properties. For a given set of properties of laminate targets, the absorption capability also depends on the anisotropic nature of the target material, the thickness of the target, the angle of attack and the type of projectile. Kumar and Bhart [17] studied the effect of thickness of the laminates and the angle of attack on the energy absorption by the composite laminates and the area of damage caused by impact. Lee and Sun [18] used quasi-static finite element analysis to simulate the penetration process in the graphite/epoxylaminate composites, where-in the penetration criterion is based on statistic punch test. Wen et-al [19] proposed an empirical formula for predicting the ballistic limit based on experimental observations, while Wen [20] predicted penetration and perforation of the Fibre-Reinforced Plastic (FRP) laminates based on mean pressure offered by the laminated target to resist the penetrator. Wen et al. [19], Reddy et al. [21] and Reid et al. [22] carried out a comprehensive study on the penetration and perforation of FRP laminates and sandwich panels with such laminates as skin and with foam cases in the context of offshore applications as part of the UK collaborative research programme on the cost effective use of fibre-Reinforced composites offshore. The results of penetration and perforation test performed on composite laminates and sandwich panels using flat–faced, hemispherical ended and conical-nosed indenters/missiles under quasi-static, dropweight and ballistic impact conditions with impact velocities up to 305m/s were reposted. Ballistic limits and perforation energies were determined and classifications of the responses were deduced from the test data. Experimental ISSN 2277-8616 evidence shows that projectile/ballistic impact of FRP laminates and sandwich panels with such laminates as skins and with foam cases can be categorized into low velocity impact (global) and wave-dominated (localized) responses. Wen et al [23] and He et al. [24] presented analytical equation for the prediction of the penetration and perforation of thick FRP laminates struck normally by missiles over a range of impact velocities. Gupta and Davids [25] studied the penetration resistance of fibre glass-reinforced plastics against small caliber projectiles. Their experimental results indicated that the energy absorbed increases linearly with the areal density or thickness of the laminate. Abdullah and Cantwell [26] have performed ballistic impact tests showing that the ballistic limit increases almost linearly with the thickness of the laminate. Cantwell and Morton [27] have predicted the ballistic limit for Carbon Fibre-Reinforced Plastics (CFRP) accounting for the energy dissipation in delaminating deformation and shear. These models can predict the energy absorption for thin laminates with reasonable success but underestimate the same for thick laminates, due to the absence of a well-defined conical damaged zone. The models described above are primarily based on conservation of the energy and no progressive damage propagation was considered except by [14]. To study the influence of various parameters affecting the penetration process in high velocity impact, the model should be able to describe the physical events, such as indentation, fibre breakage, de-lamination, bulging occurring during penetration. 3. METHODOLOGY 3.1 Experimental Procedure Mixed methods of experimental and numerical methods were used. The class of glass fibres used in this work is the matted woven roving E-glass procured from NYCIL Chemical Industries Nkpor, Idemili North L.G.A., Anambra State, Nigeria. E-glass class, which is a low alkali Borosilicate was initially, developed for electrical application, hence the designation E. The diameter of each E-glass fibre is about 0.01 mm with an average length of 50mm. It has a density of 2550kg/m3; Young’s Modulus of 72 GN/m3; and a strength of roughly 3.4 GN/m2. The Polyester Resin used for this work was also procured from NYCIL. It services as the polymer matrix (greatest in percentage of the reagents) for the sample preparation. The speed at which the resin sets can be controlled by the quantity of catalyst and accelerator used. Methyl Ethyl Ketone Peroxide (MEKP), served as catalyst to the reaction process. Cobalt II Ethyl Hexanoate acted as an accelerator for the release of the free of radical that enhances curing by the catalyst. Paraffin Wax was applied on the surface of mould to enhance the ease removal of the prepared sample from the mould untampered. This is also called a releasing agent. The hand lay-up method was used in formation of the composite materials. Here the polyester resin was applied on the mould evenly with the help of a hand brush to a thickness of about 1mm, then the woven roving fibres were lay-up in the mould and properly wetted out in a process known as fibre impregnation. More fibre plies were lay-up in the mould and compressed according to the required laminate thickness. For the thickness of 28 mm, 24 227 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 ISSN 2277-8616 mm, 20 mm, 16 mm, 12mm and 8mm, the number of plies were 22, 18, 15, 12, 9, and 6 respectively. The fibre content by volume fraction varies from 0.48 to 0.50. 3.2 Principle of Ballistic Penetration and Perforation It is assumed that the mean pressure () applied normally to the surface of the projectile provided by a Glass Fibre Reinforced Plastics (GFRP) laminate material to resist penetration and perforation by the projectile can be decomposed into two parts, one part is resistive pressure (s) due to the elastic-plastic deformations of the laminate material and the other is the dynamic resistive pressure (d) arising from velocity effects. Thus; ς = ςs + ςd (1) If it is further assumed that resistive pressure is equal to static linear elastic limit (e) in through-thickness compression of the GFRP laminates [8, 9], that is s = e and that the dynamic resistive pressure (d) which is a 0.5 ρ function of the parameter t ςe Vi , and is taken to be, ςd = β ρt 0.5 ςe Vi ςe (2) Then equation (3.1) can be written as ς = 1+β ρt ςe 0.5 Vi ςe (3) Where ρt and Vi are the density of the GFRP laminate and the initial impact velocity of the projectile respectively. The values of the term β were easily determined experimentally for simple geometries. For a unidirectional laminate β=1, while for a (0/90) cross-piled laminate with equal proportions of the fibre in the two direction β= 0.5. For a (±45, 90) composite with one quarter of the fibres in each direction β= 0.375. For a three dimensional random array β= 0.2 [28]. Also, the values of the parameter β in the equations have been empirically determined and are taken to be equal to 2 Sin θ 2 and 3 4ψ for conical-nosed and ogival-nosed projectiles respectively [20]. For fibrereinforced plastic it has been observed in the static indentation tests [14] that the first term in equation (3) is related to the static strength of FRP laminates in compression in the two principal directions, through the thickness and in-plane. Abdulla and Cantwell [26] used eqn. (3) to predict the ballistic limit of fibre-metal laminates. The same assumption (eqn. 3) was used by Ben-Dor et al [29] in their study of the penetration of fibre-reinforced plastic. 3.2.1. Penetration of Semi-Infinite GFRP Laminates The types of projectiles (life bullets) that were used are the rigid projectile with ogival and conical nosed. 228 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 D D L L 𝛗 S ISSN 2277-8616 LN LN (a) (b) Fig. 1: Projectile geometries (a) Ogival nose and (b) Conical nose The projectiles are assumed to have density ρp and mass M with diameter D (or radius r), L and LN are the lengths of the shank and nose of ogival and conical projectile as shown in Fig. 1. Fig. 1(a) shows the ogive profile as the arc of the circle(s) that is tangent to the shank. It is also FRP dp common to define the ogive in terms of caliber – radius – head (CRH); S CRH = = ψ (4) 2r Fig. 2: Schematic diagrams of a conical-nosed projectile impacting on semi-infinite FRP laminate targets (i) dp < LN; (ii) dp > LN. Fig. 2 shows the impact of a rigid projectile with conical nose on an FRP laminates target at normal incident with an initial impact velocity Vi. Two situations may arise depending upon the initial kinetic energy of the projectile as shown in Fig. 2. One situation is that the final depth of penetration has not reached the shoulder of the projectile when its kinetic energy has been dissipated and the other is that the final depth of penetration is greater than the nose length. Similar situations may occur for a rigid ogival-nosed projectile transversely impacting an FRP laminate target. 3.2.2 Conical-Nosed Projectiles For a rigid conical-nosed projectile, the motion and the final depth of penetration can be calculated if the resistive forces are known. Case (i), dp ≤ LN The resistive force of a conical-nosed projectile penetrating an FRP laminate target at normal incidence can be written as; F = σA (5) Where F is the resistive force and is the mean resistive pressure provided by the target material and A, is instant cross-sectional area. θ A = πdp 2 tan2 (6) 2 dp FRP T T and dp is the cone angle and the depth of penetration respectively. Substituting equations (3) and (5) in (6) gives; F = πdp 2 tan2 ρ θ 1+β t 2 σe 0.5 V i σe (7) For energy conservation, one obtains; dp Ek = (8) Fd dp 0 Where Ek; is the initial kinetic energy of the projectile. Substituting equation (7) in (8) will yield. Ek = dp 3 A 0 3LN 2 1+β ρt σe 0.5 Vi σe (9) Using tan (/2) = r/LN and Ao = r2. Here Ao is the crosssectional area of the projectile shank. Substituting Ek = 1 mVi 2 into equation (9) and rearranging gives that, [20]. 2 ρp ρt V i 2 dp 1 = LN ρt σ e 2 ρ 0.5 L+ 1+β t Vi 3 σe 3 And m = A0 L + LN 3 dp LN 2 (10) ρp Case (ii) dp > LN The resistive force F can be written as; 229 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 𝐹 = 𝐴0 𝜎 = 𝐴0 𝜎𝑒 1 + 𝛽 𝜌𝑡 𝜎𝑒 ρp ρt V i 2 ρt σ e 0.5 𝑉𝑖 dp = L + 8ψ3 ηγ (11) According to energy balance, one obtains, LN Ek = + p Fd dp + 0 0.5 Vi (13) Substituting Ek = 1 2 GVi 2 into (11) and using G = A0 L + LN 3 ρp gives the final depth of penetration as; ρp ρt V i 2 ρt σ e 1 ρ 1+β t σe Vi 4ψ − 1 0.5 − 8ψ3 η γ L + 8ψ3 ηγ (19) 3.3 Ballistic Limit Condition of GFRP Laminates. The ballistic limit condition for a GFRP laminate with finite thickness T, struck transversely by a rigid projectile with conical or ogival noses can be estimated by the energy balance method. There are three phases of penetration for a rigid projectile with conical or ogival nose impacting on a finite plate. First the nose enters the plate, second, the nose is fully embedded and finally, the nose exits the plate. From energy consideration, it is easy to show that; Eb = πr2 Tσe 1 + β 0.5 Vi 1 2 + L 3 +1 LN Substituting Ek = mVb 2 2 rearranging yields. (14) dp= (4Ψ − 1)0.5 − 2Ψ cos φ r (16) In which φ is the tip angle, r is the radius of the projectile, and the mean resistive pressure � is determined by Eq. (3) φo and η are evaluated as follows; 2ψ − 1 2ψ + (20) Vb into the above equation and 0.5 (21) t ρp L + 8Ψ 3 ηr Vi2 = − cos φ + 1 3 cos 3 φ − Ψ − 1 2 sin 2φ sin φ0 16Ψ³rςe (15) − sin² φ0 cos φ + π 2 sin φ0 + η (17) 1 ρ 2 1+β t σe 0.5 0.5 Case (i) dp < LN Case (ii) dp > LN ρp ρt V i 2 dp = L + 8ψ3 ηγ ρt σ e ρt σe πβ ρt σe D2 T 8m Vb = 1+ 1+ 2 4m πβ ρ D2 T 3.2.3 Ogival-Nosed Projectiles −1 0.5 (12) Fd dp ρ 2 E k = dp − L N A 0 σ e 1 + β t 3 σe φ0 = Sin 1 ρ 2 1+β t σe LN Substituting (7) and (11) in (12) yields; LN dp = L + 3 ISSN 2277-8616 Where Vb is the critical impact velocity or ballistic limit and m is the mass of the projectile. The residual velocity can also be determined as; Vr = Vi − Vb (22) 4. BALLISTIC TEST The Ballistic or resistance to penetration tests were successfully done at the Nigerian Police Force (NPF) weapon divisional shooting ground at Uwani, Enugu, Nigeria. Six composite laminate armour sample plates of size 300mm by 400mm and thicknesses of 8mm, 12mm, 16mm, 20mm, 24mm and 28mm were targeted using two types of life bullets (Ogival and Conical nosed) of equal diameter and mass. The rifle used was the Beretta Cal 9 x 19 parabellum models 951 of muzzle velocity of 355m/s and the angle of attack was 00(normal). Figs. 3 to 8 show the ballistic impact, perforation and penetration on the six GFRP composite laminate samples. 0.5 Vi 4ψ − 1 0.5 − 8ψ3 η γ L + 8ψ3 ηγ (18) 230 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 Fig. 3: Sample E, showing complete absorption of impact. Fig. 5: Sample C, showing some shattering and penetration, but no perforation. Fig. 7: Sample A, showing heavy shattering but no perforation ISSN 2277-8616 Fig 4: Sample D, showing minimal shattering by impact. Fig. 6: Sample B, showing sign of penetration but no perforation. Fig. 8: Sample F, showing failure with complete perforation. 231 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 It was observed that five samples resisted or arrested the assault of the projectiles while the sixth sample failed (the bullets went through). The distance between the target and the gun was measured to be 50meters. After the ballistic experiment, the samples were examined. The Ultrasonic thickness measurement/Penetration and inspection was carried out on the six GFRP composite samples at BVL SAMPLE E D C B A F ISSN 2277-8616 Nigeria Limited Port Harcourt, Rivers State, with Calibration Sensitivity Compression-Wave and Share-Wave Scanner. For composite analyzer probe of procedure ASTM E258007, the calibration was set at 200mm screen, while the sensitivity was set at 80% full screen height for 1.5mm hole from the calibration block. Scanning and transfer loss reduction values are as indicated in Table 1. Table 1: Ultrasonic Thickness Measurement/Penetration Inspection Result. PENETRATION TYPE OF ORIGINAL MEASURED OR PROJECTILE THICKNESS THICKNESS REDUCTION TYPE USED (mm) (mm) (mm) TEST OF Conical 28 10 18 PEN. TEST Ogival Conical Ogival Conical Ogival Conical Ogival Conical Ogival Conical Ogival 28 24 24 20 20 16 16 12 12 8 8 12 7 8.5 4 6 2.5 4 1 2 0 0 16 17 15.5 16 14 13.5 12 11 10 8 8 PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST PEN. TEST 4.1 Ballistic Test Results Equations (5) to (19) were compared with the experimental data for indentation, penetration and perforation of GRP laminate target samples by the rigid conical and ogival nosed projectiles. The values of the parameter (β) in the equation have been empirically determined and are taken to be 2sinθ/2 and 3/(4Ψ) for conical-nosed and ogivalnosed projectiles respectively. Wen(2000). (i) (ii) The values of ballistic limit or critical impact velocity Vb, ballistic or critical impact energy Eb and residual velocity VR are obtained with equations (20),(21) and (22) and are shown in Table 3. The values of thickness T, from zero(0) to 7, gave the theoretical values of Vb, Eb and VR. 4.1.1 Conical Nose Projectile For the condition dp ≤ LN (i) The values of the resistive force and kinetic energy were determined with equations (7), (9) and (10) using the material properties of the composite sample and projectile properties in Tables 2 and 3. (ii) Resistive force, Fi = 4.285N (iii) Kinetic energy, EKi = 107.12Joules and the depth of penetration, dp = 0. These values are in good agreement with the theoretical values of initial condition obtained from literature. Wen( 2000). For the condition dp ≥ LN (i) The values of resistive force, kinetic energy and depth of penetration were determined with equation (11), (13) and (14) considering projectile and sample properties in tables of initial condition (Table 2). (ii) The values of resistive force F, the absorbed energy Ek, and depth of penetration dp are shown in Table 3. The values of thickness T from zero (0) to 7 gave the theoretical values of F, Ek and dp. For the ballistic limit condition (perforation) 232 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 ISSN 2277-8616 Table 2: Initial Conditions in Conical Projectile Analysis D [mm] A [mm2] Ѳ [deg] LN [mm] L [mm] ρp [Kg/m3] ρt [Kg/m3] σe [N/mm2] β σ [N/mm2] 5.7 25.52 45 6.8 10.7 11400 1650 145.83 0.7654 133426.7 Table 2 Cont’d: Initial Conditions in Conical Projectile Analysis m [g] 1.7 Vi [m/s] 355 x [m/s] 50 t [m/s] 0.14 a [m/s2] 2520.50 Fi [N] 4.28 Ei [J] 107.12 Table 3: Results Obtained in Conical Projectile Analysis T [mm] 0 1 2 3 4 5 6 7 8 9 10 12 16 20 24 28 dp [mm] 0 1 2 3 4 5 6 7 8 9 10 11 13.5 16 17 18 T/D 0 0.175439 0.350877 0.526316 0.701754 0.877193 1.052632 1.22807 1.403509 1.578947 1.754386 2.105263 2.807018 3.508772 4.210526 4.912281 Ek [J] 0 0.012225163 0.391205221 2.970714647 12.51856707 38.20363487 95.06286872 82.1558888 116.2031682 150.2504476 184.297727 218.3450064 303.4632049 388.5814034 422.6286828 456.6759622 Vb [m/s] 0 32.57527 65.14829 97.72131 130.2943 162.8674 195.4404 228.0134 260.5864 293.1594 325.7325 390.8785 521.1706 651.4627 781.7548 912.0468 600 900.00 800.00 700.00 V b [m/s] 200 Vr [m/s] Vr 355 322.4247 289.8517 257.2787 224.7057 192.1326 159.5596 126.9866 94.41358 61.84056 29.26754 -35.8785 -166.171 -296.463 -426.755 -557.047 1000.00 Theoretical Plot Experimental Plot 400 0 -200 0 Eb [J] 0 4.033387 8.690893 13.97252 19.87826 26.40812 33.5621 41.3402 49.74242 58.76875 68.41921 89.59248 139.4284 199.2503 269.058 348.8517 10 20 30 600.00 500.00 Experimental plot 400.00 Theoretical plot 300.00 Predicted plot 200.00 -400 100.00 -600 -800 0.00 0 T [mm] 5 10 15 20 25 30 T [mm] Fig. 9: Effect of Thickness on Residual Velocity Fig. 10: Effect of Thickness on Ballistic Limit 233 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 ISSN 2277-8616 500.00 y = -0.462x2 + 32.68x - 93.64 R² = 0.996 450.00 400.00 350.00 Ek [J] 300.00 250.00 Experimental plot 200.00 Theoretical plot 150.00 Predicted plot 100.00 50.00 0.00 0 5 10 15 20 25 30 T [mm] Fig. 11: Effect of Depth of Penetration on Ballistic Limit Fig. 12: Effect of Thickness on Absorbed Energy 600 400 Theoretical Plot y = -x + 355 R² = 1 Experimental Plot Vr [m/s] 200 0 -200 0 200 400 600 800 1000 -400 -600 Vb [m/s] -800 Fig. 13: Effect of Ballistic Limit on Ballistic Energy Fig. 14: Effect of Ballistic Limit on Residual Velocity 4.1.2 Ogival-Nosed Projectile Similarly, For conditions dp ≤ LN (i) The values of resistive force, kinetic energy and depth of penetration were determined with equations (7), (9) and (16) using the material and projectile properties in Tables 4 and 5. The resistive force Fi = 4.165N and EKi = 107.165Joules and dp = 0. The condition dp ≥ LN (i) The values of resistive force, F absorbed energy EK and depth of penetration dp using equations (11), (13) and (19) with material and projectile properties in the Table 4, are shown in Table 5. For Ballistic limit condition (a) The ballistic or critical velocity Vb, critical energy Eb and residual velocity VR are obtained with equations (20), (21) and (22) and are shown in Table 5. For values of the thickness from zero (0) to 7, Vb, Eb and Vr values obtained were the theoretical values. Table 4 : Initial Conditions in Ogival Projectile Analysis Do [mm] A [mm2] LN [mm] L [mm] m [g] Vi [m/s] x [m/s] t [s] a [m/s2] Fi [N] Ei [J] 5.7 0.00 6.9 10.7 1.7 355 50 0.141 2520.50 4.28 107.12 Ѳ [deg] S 45 5.588 Table 4 cont’d : Initial Conditions in Ogival Projectile Analysis Φ φo ρp ρt σe Ψ Η β [deg] [deg] [Kg/m3] [Kg/m3] [N/mm2] σ [N/mm2] 0.9851 133368.4 29.34 37.68 22.70 11400 1650 145.833 0.7650 234 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 ISSN 2277-8616 Table 5: Results obtained in Ogival Projectile Analysis dp [mm] 0 T [mm] 0 T/D F Ek [J] Vb [m/s] Eb [J] Vr 0 0 0 0 0 355 1 1 0.175439 0.071887 0.901187 32.56103 4.033114 322.439 2 2 0.350877 0.287549 3.604501 65.1198 8.689801 289.8802 3 3 0.526316 0.646985 8.10994 97.67858 13.97006 257.3214 4 4 0.701754 1.150195 14.4175 130.2374 19.87389 224.7626 5 5 0.877193 1.79718 22.5272 162.7961 26.4013 192.2039 6 6 1.052632 2.587939 32.44901 195.3549 33.55228 159.6451 7 7 1.22807 3.403241 49.7436 227.9137 41.32683 127.0863 8 8 1.403509 3.403241 68.4203 260.4725 49.72496 94.52752 10 12 2.105263 3.403241 89.59133 390.7076 89.55319 -35.7076 12 16 2.807018 3.403241 139.4320 520.9427 139.3586 -165.943 14 20 3.508772 3.403241 199.2544 651.1778 199.1412 -296.178 15.5 24 4.210526 3.403241 269.0629 781.4129 268.9009 -426.413 16 28 4.912281 3.403241 348.8513 911.6481 348.6378 -556.648 1000 Theoretical Plot Experimental Plot Predicted Plot Vr (m/s) 200 500 0 -200 0 10 20 y = 3E-14x2 + 32.55x + 0.002 R² = 1 Vb (m/s) 400 30 Theoretical Plot Experimental Plot Predicted Plot 0 -400 0 -600 10 20 30 T (mm) T (mm) Fig. 15: Effect of Thickness on Residual Velocity Fig. 16: Effect of Thickness on Ballistic Limit 1000 y = 0.762x3 - 22.53x2 + 274.3x - 862.6 R² = 0.992 400 500 y = 0.000x2 + 0.114x - 0.000 R² = 1 Theoretical Plot Experimental Plot Predicted Plot Theoretical Plot Experimenta Plot Predicted Plot 0 0 5 10 15 20 Eb (J) Vb(m/s) 200 0 0 400 600 800 1000 Vb(m/s) dp(mm) Fig. 17: Effect of Depth of Penetration on Ballistic Limit 200 Fig. 18: Effect of Ballistic Limit on Ballistic Energy 235 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 400 400 y = -1.044x + 365 R² = 0.999 Theoretical Plot Experimental Plot Vr [m/s] 200 200 0 -200 0 y = -0.004x3 + 0.617x2 - 2.976x + 47.29 R² = 0.998 Theoretical Plot Experimental Plot Predicted Plot Ek (J) 600 ISSN 2277-8616 200 400 600 800 1000 -400 0 -600 -800 0 10 20 30 T (mm) Vb [m/s] Fig. 20: Effect of Thickness on Absorbed Energy Fig. 19: Effect of Ballistic Limit on Residual Velocity Experimental and analytical investigation have been performed concerning the static and ballistic resistance of woven roving GFRP laminate plates of thicknesses 8mm up to 28mm penetrated and perforated by ogival and conical projectiles. From the plots of the theoretical, experimental, and predictive data (Figs. 9 to 20), it is deduced that; (i) Ballistic impact is characterized by three phases namely; indentation, penetration and perforation. (ii) Ballistic limit is linearly related to the thickness of the GFRP laminate composite investigated. (iii) The ballistic limit or critical velocity increases linearly over the range of thickness of the plate investigated in correspondence with predicted values which are uniformly satisfactory. (iv)The residual velocity decreases with the increase in ballistic limit or critical velocity. (v) The ballistic limit and the peak resistive force of the plate were closely equal for conical and ogival nosed projectile. [4] Wood, R. (1980). Car Body in Glass Reinforced Plastic. Pentech Press Limited, London, pp 43 - 45. [5] Wilkins, M.L. (1964). ―Calculation of Elastic-Plastic Flow‖ Methods in Computational Physics, Vol. 3, eds., Alder, B., Furbish, S., and Rotenberg, M., Academic Press, New York , pp. 211 – 263. [6] Berholf, L.D., and Benzley, S.E. (1968). ―TOODY II, A Computer Program for Two-Dimensional Wave Propagation,‖ SC-RR-68-41, Sandia Laboratories, Alburquerque, New Mexico, November . [7] Hageman, L.J., and Walsh, J.M. (1971). ―HELP, A Multi-Material Eulerian Program for Compressible Fluid & Elastic-Plastic Flows in Two Space Dimensions and Time,‖ Vol. 1, BRL CR 39, Systems, Science, and Software, LA Jolla, Calif. 5. Conclusion This work shows that one of the governing factors in the damage resistance is the nose shape of the impacting projectile. Here the performance of the laminates could be properly tailored by controlling the strength parameters for the design against failure. It has also shown that great strides can be achieved in the production and testing (static and ballistic) of the armour protecting hand lay-up GFRP composite laminate plates. Finally for a range of thickness of the armour protecting body, the ballistic limit, residual velocities and depth of penetration were predicted for this novel GFRP composite laminates produced. [8] Wilkins, M.L., French, M.L., French, S.J., & Sorem, M. (1970). ―Finite-Difference Scheme for Calculating Problems in Three Space Dimensions & Time,‖ Proceedings of International Conference on Numerical Methods in Fluid Dimensions – II, Berkeley, California, pp. 30 – 33. REFERENCES [10] Abrate, S. (1994). Impact on Laminated Composites: Recent Advances. Applied Mech. Rev., 4711 pp. 517-544. [1] Cantwell, W.J. & Morton, J. (1989). Comparison of Low Velocity & High Velocity Impact Response of CERP Composites, 20, 545–51. [2] Prewo, K.M. (1980). The Importance of Fibres in Achieving Impact Tolerant Composites. Phil. Trans. R. Soc. London, A 294, 551 – 58. [3] Babaniyi, B. (2000). Self-reinforcing Polymeric Composite Materials in Ballistic Protection. Technical Conference of the Polymer Institute of Nigeria. November 22 and 25. [9] Johnson, G.R. (1976). ―Analysis of Elastic-Plastic Impact Involving Severe Distortions‖, Journal Of Applied Mechanics, Vol. 43, No. 3, TRANS. ASME, Vol. 98, Series E, Sept. pp. 439 – 444. [11] Cantwell, W.J. & Morton, J. (1991). The Impact Resistance of Composite Materials: A Review Composites, 22, 347 – 362. [12] Navarro, C. (1998). Simplified Modelling of the Ballistic Behaviour of Fabrics and Fibre-Reinforced Polymeric Matrix Composites. Key Eng. Mat., Vol. 141-143. 383- 403. 236 IJSTR©2014 www.ijstr.org INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH VOLUME 3, ISSUE 8, AUGUST 2014 [13] Zhu, G., Goldsmith, W., and Dharan, C.K.H. (1992). Penetration of Laminated Kevlar by Projectiles – II Analytical Model Int. J. Solids Structure, Vol. 29, 421-436. [14] Zhu, G., Goldsmith, W., and Dharan, C.K.H. (1991). Penetration of Laminated Kevlar by Projectiles – I Experimental Investigation. Int. J. Solids Structure, Vol. 29, pp 399-420. [15] Vinoson J.R. and Walker J.M. (1995) Ballistic Impact into Composite Material Structures. American Society of Aero and Astrophysics. Paper no AIAA-95-1388CP. [16] Sun,C.T. and Potti,S.V. (1995) A Simple Model to Predict Residual Velocities of Thick Composite Laminate Subjected to High Velocity Impact. International Journal of Impact Engineering. Vol. 16, No 6, Pp 1-15. [17] Kumar, K. Siva and Bhat, T. Blakrishna. (1998) Response of Composite Laminates on Impact of High Velocity. Key Engineering Materials. Vol. 141-143, Pp 337-348. ISSN 2277-8616 [25] Gupta, B.P. and Davids, N. (1966) ―Penetration Experiments with Fibre-reinforced Plastics.’’ Experimental Mechanics. Pp 445-450. [26] Abdullah, M.R; Cantwell, W.J. (2006) The impact resistance of fibre-metal laminates based on glass fibre reinforced polypropylene. Polymer Composites. Vol. 27, no. 6, Pp 700 – 708. [27] Cantwell, W.J., and Morton, J. (1990). Impact Perforation of Carbon Fibre-Reinforced Plastic. Comp. Sci. Tech., 38, 119-41. [28] Edelugo, S. O. (2000). Damage Evaluation & Reinforcements, Combination in the Development of GRP Automobile body Work. Ph.D. Thesis, University of Nigeria, Nsukka. pp 1-300. [29] Ben-Dor, G., Dubinsky, A. and Elperin, T., (2002) ―Optimization of the nose shape of an impactor against a semi-infinite FRP laminates‖, Composites Science and Technology, Vol. 62, No. 5, Pp. 663 – 667. [18] Lee, S.W.R. & Sun, C.T. (1993) Dynamic Penetration of Graphite Epoxy Laminates Impacted by a BluntEnded Projectile. Comp. Sci. Tech., Vol. 49, 369-80. [19] Wen, H.M; Reddy, T.Y., Reid, S.R and Soden, P.D. (1998). Indentation, Penetration, & Perforation of Composite Laminates & Sandwich Panels under quasi-static & projectile loading. Key Engineering Material, 141-143, 501-52. [20] Wen, H.M. (2000). Predicting the Penetration & Perforation of FRP Laminates Struct Normally by Projectiles with Different Nose Shapes. Composite Structures, Vol. 49, pp 321 –329. [21] Reddy, T.Y., Wen, H.M., Reid,S.R. and Soden P.D.(1998) Penetration and Perforation of Composite Sandwich Panels by Hemispherical and Conical Projectiles. Trans. ASME. Journal Press Ves. Tech Vol. 120, Pp 186-194. [22] Reid,S.R., Wen, H.M., Seden P.D. and Reddy T.Y. (1999) Response of Single Skin Laminates and Sandwich Panels to Projectile Impact. In: Wang S.S., Willians J.J. and Lo, K.H. Editors. Composite Materials for Offshore Operation-2. Amer Bur Shipp, Pp 593-617. [23] Wen, H.M. (2001) Penetration and Perforation of Thick FRP Laminate. Composites Science and Technology, Elsevier, Vol. 61, Pp. 1163 – 1172. [24] He, T., Wen, H.M., and Qin, Y, (2007) Penetration and Perforation of FRP Laminates Structure Transversely by Conical-nosed Projectiles. Composite Structures, Elsevier, Vol. 81, Pp. 243-252. 237 IJSTR©2014 www.ijstr.org