Tektronix -

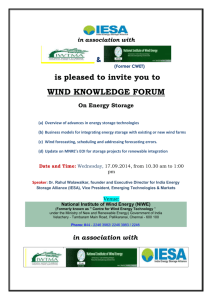

advertisement