5. Selection of Tightening Tools

advertisement

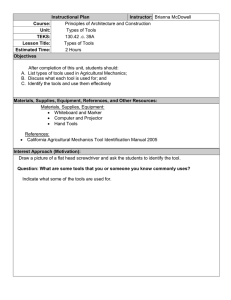

TECHNICAL DATA TECHNICAL DATA 5. Selection of Tightening Tools 5-1. Flow Chart of Tool Selection Flow Chart of tool selection ─ ─────────── 62 5-2. Selection of Manual Torque Tools (1) Selection process ─ ────────────── 64 (2) Selection of tools by application─ ──────── 64 (3) Optimum capacity─ ────────────── 65 5-3. Selection of Power Torque Tools (1) Selection process ─ ────────────── 66 (2) Tightening times of tools ─ ─────────── 66 5-4. Selection Standards of Tightening Tools Selection standards of tightening tools ─ ────── 67 60 60-61jcs3.indd 1 TOHNICHI TORQUE HANDBOOK Vol.7 08.12.4 1:10:46 AM 5 Tightening Control System For the tightening torque, it is necessary to decide the accuracy of tightening control according to the importance of the tightening position, and to choose and to control the necessary torque tools. Table 5-1. Bolt tightening control system Class A B Control Tightening system tolerance Standard Individual ±30% ±20% C Individual ±10% D Individual ±5% (Angle method) Application Application example Threaded joint for use in fixing parts subject to no external force · Bolts tightened to static parts · Bolts fixing covers (Non air-tight) Threaded joint with high safety margin in fixing, airtightness and transfer against external force Application tightening equipment Selection by model and capacity. (No torque control) Tightening equipment control Torque assurance system Periodical maximum performance measurement. Periodical inspection by retightening method. (α=1.05) · Bolts tightened to dynamic parts. Torque-controlled (Bolt strength classification not tightening device. (Indirect control device) specified) · Bolts for low pressure sealing. Periodical tightening torque measurement. Daily inspection by retightening method. (α: measured values) Threaded joint with low safety margin in fixing, airtightness and transfer against external force · Bolts tightened to dynamic parts. Torque-controlled (Bolt strength classification tightening device. (Direct control type) specified) · Bolts for high pressure sealing. Periodical tightening torque measurement. Daily tightening torque check. Daily inspection by retightening method. Daily check of tightening device. Threaded joint limitedly designed in fixing, airtightness and transfer against external force · Main bolt for connecting rod of engine. · High pressure hydraulic equipment. Periodical tightening torque measurement. Daily tightening torque check. Monitoring. Daily check of tightening device. Nutrunner with torque control. (with monitoring angle) Technical Data 60-61jcs3.indd 2 61 08.12.4 1:10:47 AM TECHNICAL DATA TECHNICAL DATA 55--111 Chapter Selection of Tightening Tools 5-1. Flow Chart of Tool Selection Is quantity more than 100 bolts per day? Yes No Power type Electric Semi-automatic Fixed Fixed Fixed or Portable Portable Pistol Power source Air Tightening method Fully automatic Fixed or Portable Portable Shape Angle Straight Electric multiple unit DCME Battery operated torque screwdriver HAT Electric nutrunner DAP Semi-automatic airtork Multiple unit ME MC AC Pneumatic screwdriver AUR Pneumatic nutrunner AP Pneumatic screwdriver U Angle nutrunner AS AS AC DCME AUR ME U HAT 62 62-63jcs3.indd 1 DAP MC AP TOHNICHI TORQUE HANDBOOK Vol.7 08.12.5 7:21:10 PM Selection of Tightening Tools Chapter 5-1 Manual type Application Tightening Work Indicating type Selection of Tightening Tools Inspection Click type Prelock Indicating method Analog Preset Adjustable Beam Analog style Torque setting style Dial indicating Digital torque screwdriver STC Digital type torque wrench CEM3 Dial indicating torque screwdriver FTD-S Dial indicating torque wrench DB Beam type torque wrench F Pre-lock torque wrench PQL PCL F Preset torque screwdriver RNTD Preset torque wrench SP QSP RTD STC FTD-S Adjustable torque screwdriver RTD Adjustable torque wrench QL CL PQL CEM3 RNTD QL DB PCL SP CL QSP Technical Data 62-63jcs3.indd 2 63 08.12.5 7:25:50 PM TECHNICAL DATA TECHNICAL DATA Chapter 5-2 Selection of Tightening Tools 5-2. Selection of Manual Torque Tools (1) Selection process 1) Purpose of use (torque measurement or large quantity tightening) Beam type, Dial type, Adjustable type, Preset type 2) Head shape Fixed square drive, Ratchet, Open end, Ring head, Interchangeable head 3) Torque value for use and / or frequency of use Table 5-2. Selection of manual torque tools Indicating type Type Beam Main applications General tightening work, testing and maintenance Measuring torque Type comparison Digital Adjustable Read the deflection of the Read the torsion from Read the digital display beam spring directly from the torsion bar, which is for the output of the strain the graduated plate magnified by the dial gauge Structure Model Click type Dial Precise tightening work, Precise tightening work, research and testing research and testing Preset When the torque reaches the preset value, a click is heard and impulse is felt When the torque reaches the value set by the tester, a click is heard and impulse is felt Particular bolt tightening, General tightening work, Tightening for mass production Tightening for mass production ○ ◎ ◎ x x ○ ○ △ ○ x x x x ○ ◎ Accuracy ○ ◎ ◎ ○ ○ Ease of work △ ◎ ◎ ◎ ◎ Price ◎ △ x ○ ◎ SP, RSP, QRSP, QSP, CSP, BQSP, BCSP NTD, RNTD Ordinary tightening for multiple purpose Tightening a number of screws of the same type ◎ F, SF, QF, FR, QFR, CF Torque wrench Torque screwdriver DB, DBE, T CEM3 ◎ QL, QLE, CL, CLE, PQL, TiQL, TiQLE (ATG), MTD, FTD-S STC ◎ LTD, RTD, MLD Tools marked with “ ◎ ” are standard torque wrenches or screwdrivers that are widely used. (2) Selection of tools by application Table 5-3. Selection of tools by application Application Item General usage Mass production Error-proofing system Insulated Inspection Semi-automatic Tightening by power tool Multiple tightening 64 Monitoring system 64-65jsc3.indd 1 Manual tools Torque screwdriver Power tools Torque wrench Pneumatic tool Electric tool RTD, LTD, AMRD,BMRD, AMLD, BMLD QL, QLE, CL, CLE − SP, QSP, (PQL), CSP, RNTD, NTD − QRSP, BQSP QLLS, PQLLS, QSPLS,SPLS, MPQL, AURLS,ACLS Made to Order: LTDLS FH256MC, CNA-4mk2 RTDZ PQLZ MTD, FTD, STC − − − − DB, CDB-S, T, SF, F, CF, QF, CEM3 − − − − − − − − A,AC − AUR, U, AS, AP DAP, HAT − − MG, MF, ME, MC DCME Made to Order: METC, MCTC + Display Torque wrench with sensor + Display DCMETC + Display TOHNICHI TORQUE HANDBOOK Vol.7 08.12.4 0:07:10 AM Selection of Tightening Tools Chapter 5-2 Head Shape Tightening Dual square drive Open spanner Ring head Pipe wrench Interchangeable head Notched open spanner Made-to-order head Inspection Interchangeable head Square drive (3) Optimum capacity Selection of Tightening Tools Open ratchet Ratchet Ratchet Table 5-4. Optimum capacity Tightening torque Optimum usage range (Against max. capacity) Note Below 200 [N・m] 40 to 90% Can be used at max. capacity if within 100 pcs. per day Over 200 [N・m] 40 to 70% Note: The operator may feel fatigue if the wrench is used at close to the maximum capacity. Also, the weight of the wrench will be unnecessarily heavy when it is used at low ranges. The optimum capacity is to use under the target of around 70% of maximum capacity. Example: When QL200N4 and the setting torque T = 80 [N·m], then P (Hand force) = Setting torque 80 = = 200 [N] Effective length 400 ÷ 1000 Table 5-5. Case of tightening torque: 80 [N·m] *Refer to effective length of QL model (P.174) Suitability Torque wrench to use Mass [kg] Hand force [N] Result △ QL200N4 ○ QL140N 1.40 200 Heavy 0.78 250 △ Good QL100N4 0.68 308 Large hand force required ◎ TiLQL180N 1.00 160 Light, small hand force Technical Data 64-65jsc3.indd 2 65 08.12.4 0:07:13 AM TECHNICAL DATA TECHNICAL DATA Chapter 5-3 Selection of Tightening Tools 5-3. Selection of Power Torque Tools (1) Selection process 1) Power (air, electric, hydraulic) 2) Shape (hand-held, fixed, head shape, reaction force support) 3) Capacity (tightening torque value, tightening accuracy) 4) Tightening time (rotations) Table 5-6. Selection of power torque tools Air Electric Hand-held Structure Type comparison Main applications Fixed Without reaction With reaction Auto stop by toggle mechanism Driven by pneumatic motor With reaction arm to absorb reaction during tightening Auto stop by toggle mechanism Built-in to automatic equipment Auto stop by toggle mechanism Tightening completion signal by LS General tightening of small screws Individual bolts in factories Tightening of medium and large screws Individual bolts in factories Auto tightening of many units, or multiple axis tightening Small screws Medium screws Large screws General multipurpose tightening Same screw large quantity tightening Rotation (auto speed change) Weight Noise Accuracy Operation Price Model Hand-held Without With reaction reaction Auto stop by toggle With arm to absorb mechanism reaction during Driven by electric tightening motor General tightening of small screws, or multiple axis tightening Tightening of medium and large screws Individual bolts inside and outside factories Fixed Built-in to automatic equipment Auto tightening, or control by multiple axis tightening driver Auto tightening of many units or multiple axis tightening ◎ △ x x ○ ◎ ○ ◎ ◎ ◎ △ x x ○ ◎ △ ◎ △ ○ ○ x ○ ○ x △ △ ◎ △ △ ◎ ◎ ○ ◎(○) ○ △ ◎(○) ◎ ○ ○ ○ ◎ ○ △ ○ ○ ○ ○ ○(△) ○(◎) ◎ △ ○ ◎ ○ ○ ○ △ ○ ○ ○ ○ ○ ○(△) ○(◎) ◎ △ U, AUR, AS AP MG, MF, ME, MC, AME HAT DAP DCME (2) Tightening times of tools Table 5-7. Tightening time of various tools [sec. / piece] Screw joint Screw, tightening torque M8 (P1.25) T = 22 [N·m] (e = 10) 66 Manual Power Power + Manual Semi automatic (Air motor + click type in a body) Number of thread ridges Simultaneous tightening [pieces] 10 1 9.6 8.0 3.2 5.4 4.0 3.5 10 4 7.2 6.5 1.9 3.0 2.3 2.3 16 1 14.6 12.6 4.6 7.3 6.7 5.6 16 4 12.5 10.6 2.5 4.0 4.0 3.6 Indicating type (DB50N) Click type (QL50N) Full automatic direct control (ASH40N) Impact wrench + click type (QL50N) (AC50N) (AC100N) In the test conditions, the screw is inserted into the tapped hole and the tool is placed on the table. The time interval is measured from the start of tightening until the tightening has been completed and the tool has been returned to the table. For manual tools, you may tighten the screw with your fingers. 66-67jsc3.indd 1 TOHNICHI TORQUE HANDBOOK Vol.7 08.12.4 0:07:39 AM Selection of Tightening Tools 5-4 Chapter 5-4. Selection Standards of Tightening Tools Table 5-8. Selection standards of tightening tools Name Important screw, Number, Degree of importance General screw Nominal Specification of screw Class of strength Head shape Number of tightening threads Male screw, Female screw, Number of bolts tightened Limit of strength (P = Screw thread (T-max = ) N·m/kgf·cm/lbf·in Tightening torque Tolerance Class, Washer None, Flat washer, Spring washer (Strong, Normal) Surface treatment None, Parkerizing, Plating (Zn, Cr, Lubrication None, machine oil, Wax-based oil, molybdenum disulfide ± %, T = to ) Number of bolts tightened Pieces/day (Time limit Number of bolts tightened simultaneously Pieces Coefficient of joint Hard, Medium, Soft (e = Tightening space Socket Usable Not usable On the bolt II. Tightening Tool Type Manual type Sec/piece, None) ) mm, Around the bolt mm, Swing Total length Model Manual, Powered, Manual + Powered Click type, Indicating type/ Adjustable type, Preset type Head type Square drive, Open end head, Ring head / Fixed ratchet / Interchangeable head Capacity (Ease-of-use) T Power Compressed air (Pressure Mpa or above), Electric ( V), Hydraulic Power source /weight kg, Overall length mm, Hand force N Portable, Fixed / Single Axis, Multiple Axes Type r.p.m (at ) Number of rotations Torque control method Direct control (Graduations, Non-scaled), Indirect control, Maximum capacity, No control Capacity, shape T Tightening tool / Straight, Pistol, Angle Type Sec / piece Time required for tightening $ / piece Cost of tightening Socket ( x ), Bit Hose diameter Technical Data 66-67jsc3.indd 2 mm From the top, From the side, From the bottom Direction of tightening Accessories ) Selection of Tightening Tools I. Screw joint 67 08.12.4 0:07:41 AM