IS 8872-4-4 (1984): Variable Resistors, Part 4: Preset, Section 4

advertisement

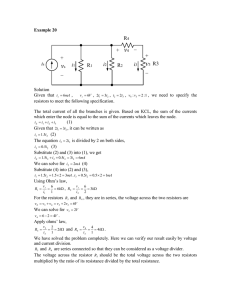

इंटरनेट मानक Disclosure to Promote the Right To Information Whereas the Parliament of India has set out to provide a practical regime of right to information for citizens to secure access to information under the control of public authorities, in order to promote transparency and accountability in the working of every public authority, and whereas the attached publication of the Bureau of Indian Standards is of particular interest to the public, particularly disadvantaged communities and those engaged in the pursuit of education and knowledge, the attached public safety standard is made available to promote the timely dissemination of this information in an accurate manner to the public. “जान1 का अ+धकार, जी1 का अ+धकार” “प0रा1 को छोड न' 5 तरफ” “The Right to Information, The Right to Live” “Step Out From the Old to the New” Mazdoor Kisan Shakti Sangathan Jawaharlal Nehru IS 8872-4-4 (1984): Variable Resistors, Part 4: Preset, Section 4: Type VRT 4 P [LITD 5: Semiconductor and Other Electronic Components and Devices] “!ान $ एक न' भारत का +नम-ण” Satyanarayan Gangaram Pitroda “Invent a New India Using Knowledge” “!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता ह” है” ह Bhartṛhari—Nītiśatakam “Knowledge is such a treasure which cannot be stolen” IS : 8872 ( Part 4/Set 4 ) - 1984 UDC: 621.316.82 ( Reaffirmed 2002 ) India/z Standard SPECIFICATION FOR VARIABLE RESISTORS PART 4 PRESET Section 4 Type VRT 4 P 0. General - This standard shall be read in conjunction with IS : 88?2 ( Part 1 ) - 1977 ‘Specification for variable resistors: Part 1 General requirements and methods of tests’. c‘ 1 ~scope _- This standard covers the requirements of cermet (non-wire wound ) multi-turn presets. The outline, drawing and dimensions shall be according to Fig. 1. 2. Outline, Drawing aud Dimensions 2tl.5 FiG. 1 OUTLINE, DRAWING AND DIMENSIONS Gr. 5 @ May 1985, IS1 Adopted SO November 1984 I I INDIAN STANDARDS INSTITUTION MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG NEW DELHI-l 10002 IS : 8872 ( Part 4/Set 4 ) - 1984 2.1 Characteristics a) Climatic category 55/100/56 b) Low air pressure 2 kPa c) Acceleration 1 km/s2 d) Bump 4 000 bumps e) Vibration 10 to 2 000 Hz, 200 m/s2 f) Shock 1 km/s2 g) Preferred resistance values See Table 1 h) Rated working voltage See Table I j) Selection tolerance f 10 percent k) Rated dissipation at 70°C 0.5 W (see Note) f m) Temperature characteristic of resistance f 2 percent n) Stability after endurance electrical p) 100 ppm/“C, f 250 ppmrC 125°C Maximun surface temperature q) Effective electrical travel 15 turns Min 20 turns Max r) Typical construction Cermet ( non-wire-wound Note - For ratings at temperatures TABLE 1 PREFERRED ) other than 7O”C, reference shall be made to the derating curve shown in 3. RESISTANCE VALUES AND RATED WORKING VOLTAGES Rated Working Voltage Resistance V 7 100 D 200 n 10.5 470 sz 15.3 lk 22’4 2.2k Q 33.2 4*?k bb 48.5 10k B 70.7 22k Q 105 47k 9 153 1OOk n 224 220k rlz 250 470k Q 250 IM D 250 - 2 IS : 8872 ( Part 4/Set 4 ) - 1984 3. Derating:Curve 0 20 40 140 4. Marking - See 6 of IS : 8872 ( Part 1 ) - 1977. In addition, the temperature marked. 160 co-efficient shall also be 5. Material, Construction and Workmanship - See 5 of IS : 8872 ( Part 1 ) - 1977. 6. Tests 6.1 ClassiJca tion ofTests 6.1.1 Type tests - The sequence of type tests and requirements shall be in accordance with Table 3. 6.1.1.1 The manufacturers shall submit 48 samples in each style for which the approval is required, having the numbers and values as follows : a) 14 samples of the highest value, and 2 spares; b) 14 samples of the lowest value, and 2 spares; and c) 14 samples of the middle value, and 2 spares. Note - When approval to variable resistors of closer temperature characteristic of resistance is desired, two specimens each of the highest, the middle and the lowest resistance value shall be submitted for approva! testing and these shall be subjected to the tests of Group 0 and VII. 6.1.2 Routine tests every resistor : The following shall constitute the routine tests and shall be carried out on each and a) Visual examination, b) Continuity, c) Element resistance, and d) Sealing. 6.1.3 Acceptance tests - For the purpose of the acceptance of the lot, all samples shall be subjected to the tests as given in 6.1.2. The following two groups of samples Group A and Group B) shall be drawn and the resistors in each group shall be subjected to the tests as speci Bed in the Table 2. IS : 8872 (Part 4ISec 4) - 1984 TABLE 2 SCHEDULE Clause Ref in IS : 8872 (Part l)-1977 51 No. Tests (1) (2) 9 Group A Voltage (4) D/ND (5) (6) 9.1.1 proof (2 seconds) Operating Contact TESTS Inspection* Level AQL (Percent Defective) (3) Dimensions ii) OF ACCEPTANCE 8.9 torque 9.2 resistance variation II ND s:; ND 8.12.4 Group B Sub-group B I Solderability 9.8.3 Sub-group B 2 Resistance to soldering Rohustness heat 9.8.4 of terminations 9.7 Endurance (mechanical) (200 cycles) 11.3 Resistance 11.1 to solvents s3 D s3 D s3 ND Sub-group B 3 Settability Bump 9.10 Climatic 10.1 Sub-grdup B 4 Endurance (electrical) D=Destructive, Note - * Sea IS (168 h) 11.4 ND-Non-destructive. : 10673-1984 Sampling 6.2 General Conditions for Tests- plans TABLE (11 i) Test (2) and procedures for inspection by attributes for electronic items. See 7 of IS : 8872 ( Part 1 > - 1977. 6.2.1 The test schedule and the requirements 61 No. 4 shall be in accordance with Table 3, 3 TEST SCHEDULti Clause Ref in IS : 8872 ( Part 1 ) - 1977 AND REQUIREMENTS Condition of Test (4) (3) Requirements (5) 0 Group ( 48 Samples ) a) Visual examination - 9.1 The condition, workmanship and finish shall be satisfactory. Marking shall be legible and indelible. ( Continued ) 4 IS : 8872 ( Part 4/Set 4 ) - 1984 TABLE SI No. 3 TEST SCHEDULE Co& Requirements (5) (4) (3) (21 - Condition of Test Clause Ref in IS : 8872 (Part 1) - 1977 Test (1) AND REQUIREMENTS The adjustment be operated slowly. device steadily shall and The change in resistance shall be smooth continuous and unithroughout the directional actual effective electrical level. b) Continuity 8.1 c) Dimensions 9.1.1 The dimensions of the resistors and their terminations shall confirm to the values given in Fig. 1. d) Element resistance 8.2 l%is shall be within the selection tolerance of f 10 percent. c) Terminal resistance 8.3 The end resistance at either end of the resistor shall not exceed 20 Sz or f 2 percent of the total resistance value whichever is greater.. f) Minimum effective resistance and angle of ineffective rotation 8.5 g) h) jj k) - 8.5.1 This is the angle between the two positions recorded above. Value of minimum effective resistance. (from termination n j 8.5.1 This is the resistance measured above. Angle of effective rotation and value of minimum effective resistance ( from termination c ) 8.5.2 Voltage proof Insulation resistance Integrity Perpendicular Operatiog torque value as - 8.6 The angle of effective shall be : 15 Turns, Min 20 Turns, Max rotation 8.9 900 V rms for one minute. rhere shall be no breakdown or flashover shall occur. 8.10 500 v. rhe value shall than 1000 8. be not less Resistors shall be mounted on an appropriate mounting fixture with their bodies restrained from movement . of shaft - 1) Pull force m) The resistance value at angular positions are recorded for information only. Angle of ineffective rotation ( from termination a ) Effective resistance and angle of effective rotation 2) - A force of 23 N shall be applied Resistors shall be examined for evidence of shaft breakage. iz force of 10 N shall be applied in a direction perpendicular to the axis of the operating shaft for 1 minute, Min. Resistors shall be examined for evidence of shaft breakage. along the axis of the operating shaft, away from the body of the resirtor. The force shall be maintained for one minute, Min. force 9.2 The operating torque to operate the contact approximately 10, 50 percent of the actual electrical travel shall mined. required arm at and 90 effective be deter- The operating be a maximum torque shall of 10 mNm. ( 5 Continued ) IS : 8872 ( Part 4/Set 4 ) - 1984 TABLE 3 TEST SCHEDULE AND REQUIREMENTS - Contd Teat i!. i2) (1) n) Clutch operation p) Sealing q) Contact resistance ii) Condition of Teat Clause Ref in IS : 8872 ( Part 1) - 1977 (4) (3) - 9.4.2 - 11.5.2 8.12.4 Requirements (5) arm shall idle The contact against the stop without electrical discontinuity or evidence of mechanical damage. The travel of the contact arm shall also be capable of reversing directon. No bubbling shall occur. Number of cycles-6 The contact resistance variation shall not exceed 3 percent or 352 whichever is greater. First Croup ( 12 Samples) a) Settability - b) Solderability 9.8.3 c) Robustners of terminations 9.7 Tensile : 10 N. In addition, the test shall be carried out in the opposite direction, bending : $z bend, to be bent through 0 d) Bump+ 9.10 4 000 bumps The resistor wiper shall be set at approximately 30, 50 and 75 percent of mechanical rotation. A dc voltage of up to 2.5 V shall be applied across the end terminals, and the wiper shall then be adjusted smoothly without abrupt voltage change at each test point. The settability error shall be within the limits specified. - The settability error within * 1 pe:cent shall be As in IS : 8872 (Part l)-1977. As in IS : 8872 (Part l)-1977. 1) Setting stability - - The change shall not exceed f 1 percent 2) Continuity 8.1 - As in Sl No. (i) (b) . 3) Klement resistance 8.2 - The change in the resistance from the initial value shall not exceed f (1 percent + 0.059). 9.1 - There shall be no fracture, loosening of parts or other mechanical damage. 4) Visual examination e) Vibration* 9.9 10 to 2 000 Hz, 200 m/s2 1) Setting stability The f 2) Continuity 8.1 3) Element resistance 8.2 change shall 1 percent. not exceed As in Sl No. (i) (b). - The change in the resistance from the initial value shall not exceed f ( 1 percent + 0.05 0). *Throughout the test the resistors shall be connected to a suitable monitoring- device to determine electrical discontinuity. It is desirable that the detecting equipment shall detect any interruption with a duration of 0.1 millisecond or greater. ( Continlled) 6 IS : 8872 ( Part 4/Set 4 ) - 1984 TABLE 3 TEST Test BE. (2) (11 AND - Conld Clause Rof in Is : 8872 ( Part 1 )-1977 Condition of Test Raqoircmerts (3) (4) (5) - There shall be no loosening of parts mechanical damage. fracture, or other 1 km/s’ 9.11 Shock* 1) Setting REQUIREMWTS 9.1 4) Visual examination f) SCHEDULE - stability The f shall change 1 percent. not exeeed 2) Continuity 8.1 As in Sl No. (i) (b) . 3) Element 8.2 The change in resistance from the initial value shall not exceed i (1 percent + 0.05 Sz ) resistance g) Acceleration* 1) .Setting There shall be Fno fracture, loosenmg of parts or other mechanical damage. 9.1 4) Visual examination 1 km/s* 9.12 The f stability change shall 1 percent. .not exceed 2) Continuity 8.1 As in Sl No. (i) (b). 3) Element resistance 8.2 The change in resistance from the initial value shall not exceed i ( 1 percent + 0.05 51). 4) Visual examination 9.1 There shall be no loosening of parts mechanical damage. - The change shall at 1 percent. fracture, or other 551125 10.5 h) Rapid ehange of temperature - 1) Setting stability not exceed 2) Continuity 8.1 - As in Sl No. (i) (b). 3) Element 8.2 - ‘The change in resistance from the initial value shall not exceed f 1.5 percent. 9.1 - There shall be no loosening of parts mechanical damage. 10 - resistance 4) Visual examination j) Climatic tests 1) Dry heat 2) Damp heat ( accelerated 3) Cold test 4) Operating torque 5) Low air pressure ) - 10.1.2 At + lOO”C, 16 h 10.1.3 One cycle 10.1.4 At - 55W, 2 kPa ‘The voltage proof test shall be done at 350 V rms. 10.1.5 - 2 h - 9.1 fracture, or other The value shall not exceed 1.5 times the maximum value specifiedin Sl NO. (i) (m). There shall be no breakdown or flashover *Throughout the test the resistors shall be connected to a suitable monitoring device to determine electrical discontinuity. It is desirable that the detecting equipment shall detect any interruption with a duration of O-1 millisecond or greater. ( Confinued ) 7 IS : 8872 ( Part 4/Set 4 ) - 1984 TABLE SI No. Test (1) (2) 10.l.G -_ Con&f Requirements (5)’ (4) - 5 Cycles The voltage to be applied shall be the rated voltage. There thall be no or flashover. breakdown : 1) Visual examination 9.1 There shall be no corrosion fracture, loosening of parts or mechanical damage. other Marking shall be legible and indelible. 2) Continuity 8.1 As in Sl No. (i) (b). 3) Element 8.2 ‘The change in resistance from the initial value shall not cxteed f 2 percent. resistance 4) Insulation 5) Voltage iii) Second Grouj Resistance proof 8.10 The value shall than 1OOMP. 8.9 There shall be no or flashover. be not less breakdown (6 Samples) 10.2 a) Damp heat (long term) i) Working iv) ) - Condition of Test (3) test Final Meamrcmentr AND REQUIREMENTS Clause Ref in IS :8872 ( Part 1 )- 1977 6) Damp heat ( accelerated remaining cycles i) Working 3 TEST SCHEDULE - test A dc voltage of 20 f 2 V shall be apphed to half the specimens between termination ‘b’ and the external metal parts ( termination being positive ) and no voltage shall be applied for the other half specimens. The voltage to be applied be the rated voltage. shall - _ ‘There shall be no or flashover. There shall be no corrosion fracture, loosening of parts or mechanical damage. other Marking shall be legible and indelible. 1) Visual examination 9.1 2) Elcrnent resistance 8.2 3) Insulation 8.10 - ‘The value shall than 100 M Q. 4, Voltage proof 8.9 -- There shall be no or flashover. 5) Solderability 9.8.3 resistance breakdown The change in resistance from the initial value shall not exceed f 2 percent. be not less breakdown As in Sl No. (ii) (b). l’hird Groub ( 6 Samfiles) a) Bndurancc ( mechanical ) 11.3 200 cycles. 1 cycle in 2.0 += O-5 minutes. The specimens shall be mounted by their normal mounting means on a I.6 mm thick glass epoxy laminate. The specimens shall be ganged in pairs and each pair shall be connected in series so that a nominally constant current flows through the resistors, irrespective of the contact arm position during the turning of the lead screw actuator. ( Continued) 8 IS: 8872 ( Part 4/Set 4 ) - 1984 TABLE Sl No. Test ( SCHEDULE AND REQUIREMENTS Requirementm (5) (4) 1j Visual examination - There shall be no loosening of parts mechanical damage. 2) Continuity 8.1 - As in Sl No. (i) (b). resistance fracture, or other The change in resistance from the initial value shall not exceed f 2 percent. 8.2 Fourth Group ( 6 Samples ) a) Endurance ( electrical ) 1) Vilual cxaminatlon At + 7o” c. The specimens shall he preconditioned at the test temperature for a period of 8 hours before the start of the test. The specimens shall be normal their mounted hy means on a 1.6 mm thick glass epoxy laminate. The specimens shall be so arranged that the temperatnre of any one specimen shall not appreciably influence the temperature of any other specimen, There shall he no undue draft over the resistors. 11.4 - 9.1 There shall be no fracture, or any other ‘mechanical damage. Marking shall be legible and indelible. 2) Continuity 8.1 As in Sl No. (i) (b). 3) Element 8.2 The change in resistance from the initial value shall not exceed f 2 percent. resistanee 4) Insulation resistance 5) Voltage proof - 8.10 7) Operating torque h) Flammability As in Sl No. (i) (j) There shall be or flashover. 8.9 The f 6) Setting stahility no change shall 1 percent. breakdown not exceed 9.2 - The value shall not exceed 1’5 the maximum value times specified in Sl. No. (i) (m). 11.2 - As in IS : 8872 (Part I)-1977. 10.4 - As in IS : 8872 (Part 1)“1977. 11.1 - As in IS : 8872 Fayth Group ( 3 Samples ) a) Mould growth vii) Conrd 9.1 3) Element vi) - Coadition of Test Clause Ref in IS : 8872 Part 1 ) - 1977 (3) (2) v) 3 TEST Sixtlr &or@ ( 3 SampleJ 1 a) Resistance to solvents h) Resistance to soldering heat 9.8.4 - 1) Visual examination 9.1 - 2) Element resistance 8.2 (Part l)-1977. There shall be no fracture, loosening of parts or other mechanical deterioration. The change in resistance from the initial value shall not excecd f 1 percent + O-50) ( Continued) 9 IS: 8872 ( Part 4/Set 4 ) - 1984 TABLE SCHEDULE AND REQUIREMENTS - Test in IS : 8872 ( Part 1 ) - 1977 (2) (3) f.1) Requirements of Test (4) (5) Seventh Groufi ( 6 Sampfcs ) a) Temperature characteristic of 8.11 ‘Drying as per procedure resistance b) Salt mist 1) Visual II’ The value shall ppm/‘C or 250 applicable. be f ppm/“C 100 as 10.3 examination 2) Element ti) Conrd Condition C1aosc Rcf SI No. viii) 3 TEST resistance 9.1 There shall bc no corrosion, loosening of parts or other mechanical deterioration. Marking shall be legible and indelible. 8.2 As in Sl No. (i) (c). As in Sl No. (i) (j). 3) Insulation resistance 8.10 4) Operating torqoe 9.2 - .4s in Sl No. (i) (m). Spares ( 6 Samples) 10 Printed lt.DcIhi Priotm. lhlbi. India