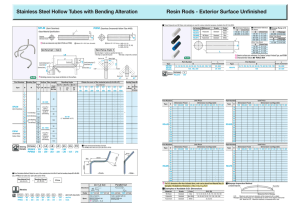

Stainless Steel Hollows with Bending Alteration Resin Rod

advertisement

Stainless Steel Hollows with Bending Alteration Resin Rod Exterior Surface Unfinished Q These Polyacetal and MC Nylon rod materials are used for various industrial purposes. Available from Ø10 to Ø200. SPLM (Semi-Seamless) PIPM (Seamless Ornamental Hollows #400) RDJJS RDJMS 0.5 Color White Blue t 1.6 MMaterial Polyacetal - Standard MC Nylon, Standard Part Number G ‹Base Material Specification› D D (Elimination of Weld Bead) EEnds are deburred only (Both SPLM and PIPM). M Material: 1.4301/X5CrNi18-10 (Annealed) Specifying Angle 3 Specifying Angle 1 · Angle 2 Bend the Angle (2) portion as specified for Angle (3). · When Angle (2) begins with UU upward · When Angle (2) begins with LL downward LB ndin Be Specify Angle (2) bent upward UU° bend downward LL° 0° RT: bend to right RT° Days to Ship gR Obtain the sum of the material price (LA+LB+LC) and the bending charge (B1+B2+B3). LA · LB · LC 80 101 201 301 401 501 601 801 Bending Charge (B) 40 ~ ~ ~ ~ ~ RT LT ~ UU LL 10 12 15 1(1st Bending) 16 2(2nd Bending) 20 2nd Bending 25 3 + 30 3rd Bending ( ) 50 100 200 300 400 500 600 800 1000 Part Number 40 Measuring Point of Warpage QVolume Discount(ERound down to one Cent.)P.87 Quantity 1~15 Discount Rate € Unit Price D L Specify in 1mm increment. 40 50 (Ornamental Hollow) 32 38 80 45 50 120 100 80 50 30~90 (Specify in 1° increment. ±0.5°) RDJJS 201~300 301~400 501~600 601~700 701~800 501~600 601~700 701~800 20~800 60 3.0 or Less 70 90 80~1000 (Specify in 1 mm increment.) 60 120 100 LA, LC≥R+ℓ LB≥2R+ℓ 0~+5.0 100 150 130 180 20~500 0~+7.0 200 QEx. 3rd-Bending · For PIPM25-B3-200-253-220-L90-UU75-RT45 Part Number UU75° D L Specify in 1mm increment. EFor orders larger than indicated quantity, please request a quotation. LA200 5~19 5% L90° + Bending Charge (B1, B2, B3) = Price (24,00+25,00+25,00) + 42,00 = 116,00 0~+3.0 Code - LT49 LT49 <Side> 60 RDJMS Alterations - 0~+1.5 50 LA · LC Cut - LA - LB - LC - U/L - UU/LL - RT/LT - 401~500 40 <Front> Alterations PIPM22 - B3 - 100 - 240 - 320 - U50 - UU35 PIPM22 - B3 - 200 - 253 - 361 - U60 - UU35 € Unit Price 30 R60 (Ex.) PIPM25-B3-200-253-220-L90-UU75-RT45 Base Material Price (LA+LB+LC) D dimension Warpage tolerance 20 LC22 LB253 R60 Type 0 RT45° QPrice Calculation Method: Obtain the sum of the material price (LA+LB+LC) and the bending charge (B1+B2+B3). (AUT · CUT · CUA · CUC) - AUT70 - CUA Parallel Cutting 20~800 70 4.0 or Less 80 0~+4.0 90 AUT (Cut) 100 AUT (LA Cut) CUT (LC Cut) Cuts LA and LC. Spec. Price Adder 2 -297 100~200 401~500 80 50 QVolume Discount(ERound down to one Cent.)P.87 B 301~400 0~+1.5 25 - 201~300 0~+3.0 100 10 Days Quantity 1~4 Discount Rate € Unit Price € Unit Price 100~200 40 80 PIPM25 - B3 - 200 - 253 - 220 - L90 - UU75 - LT45 Part Number D dimension Warpage tolerance 30 + Part Nr. - B - LA - LB - LC - U/L - UU/LL - RT/LT Order Example SPLM10 - B1 - 100 - 100 - L50 Days to Ship 35~50 10% 15 50 LA LC≥R+ℓ LB≥2R+ℓ 150 180 25 21~34 5% 25 130 22 Price 16~20 2% ·Outer Dia. Maximum and minimum diameters will be measured with a caliper. ·Warpage Rod is placed along an L-shaped Angle as shown in the diagram below and turned 360° about the outer diameter. Maximum clearance is measured with a ruler. 5.0 or Less 20 100 30 40 Round Bar Days 8 EFor orders larger than indicated quantity, please request a quotation. 80~600 (Specify in 1 mm increment.) 10 15 PIPM U L L-Shaped Angle 10 6 8 (Semi-Seamless) Straight Section LA LB LC Min. Value ℓ Price Type 2 3 4 5 SPLM Bending Angle (1) (2) (3) ~ B Hollow Length B2 (2nd Bending) B3 (3rd Bending) RT: bend to right 0° RT° B1 (1st Bending) LT: bend to left LT° ~ D Bending R Tolerance ±3 Type Bending Type EOuter diameter is unfinished. For Outer Diameter Finished Type, refer to P.299 ECharacteristic Values DRefer to P.858-859 RT90° EBending process may cause scratches on the surface. Part Number 0~+3.0 0~+10.0 QWarpage Inspection Method Part Number L Order Example RDJJS15 - 500 LT90° 10~50 60~200 L LC LC Bending R LA ℓ LT: bend to left LT° ℓ ℓ Specify Angle (1) bent upward U° bend downward L° QL Dimension Tolerance D L Dimension Tolerance M Material: 1.4301/X5CrNi18-10t=1.0 (D=10 · 15) t=2.0 (D=22 · 25 · 32) t=3.0 (D=38 · 45· 50) D3.0 Seam Ordering Code AUT100 E AUT(CUT)≥R+D 6,00 CUA (LA Side) CUC (LC Side) Cuts LB parallel. Ordering Code CUA 120 150 180 20~500 0~+5.0 200 6,00 2 -298