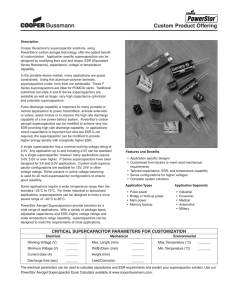

Cooper Bussmann Cat Cover

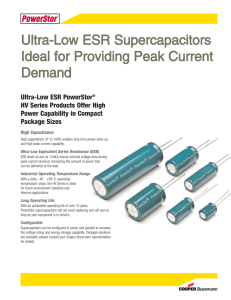

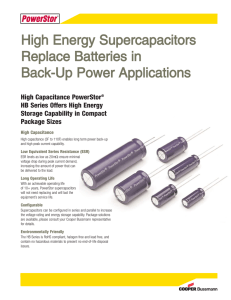

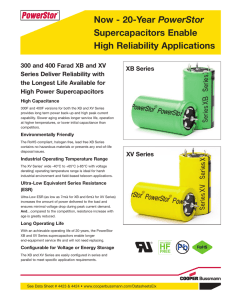

advertisement