Drill Press Safety Procedures

advertisement

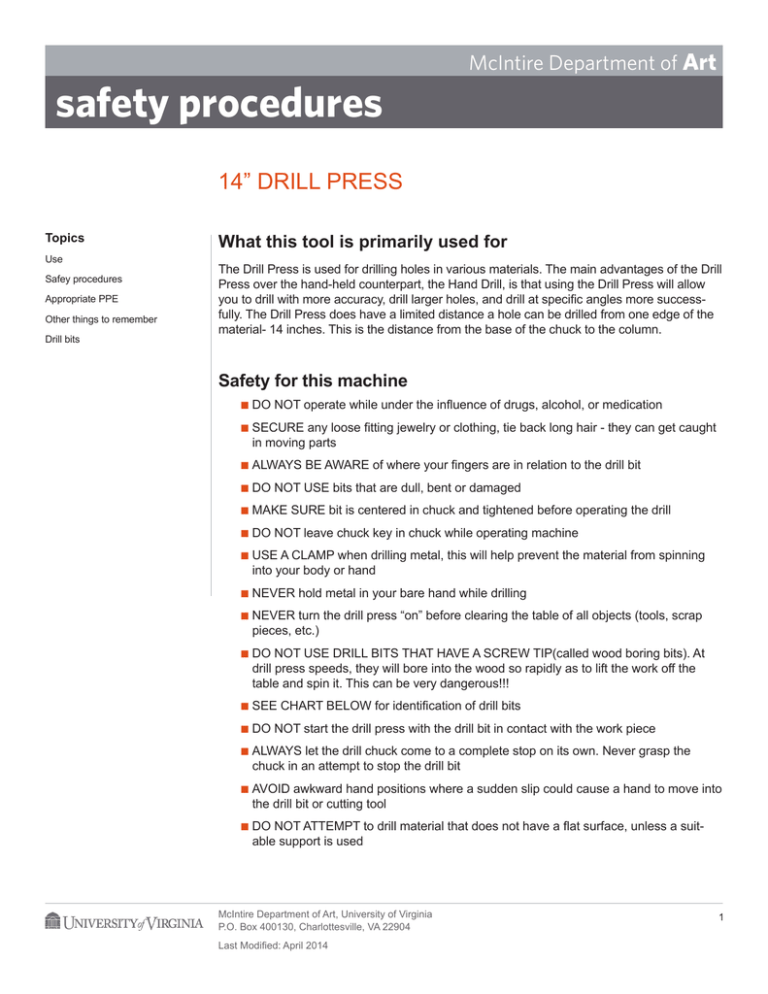

McIntire Department of Art safety procedures 14” DRILL PRESS Topics Use Safey procedures Appropriate PPE Other things to remember Drill bits What this tool is primarily used for The Drill Press is used for drilling holes in various materials. The main advantages of the Drill Press over the hand-held counterpart, the Hand Drill, is that using the Drill Press will allow you to drill with more accuracy, drill larger holes, and drill at specific angles more successfully. The Drill Press does have a limited distance a hole can be drilled from one edge of the material- 14 inches. This is the distance from the base of the chuck to the column. Safety for this machine nDO NOT operate while under the influence of drugs, alcohol, or medication nSECURE any loose fitting jewelry or clothing, tie back long hair - they can get caught in moving parts nALWAYS nDO NOT USE bits that are dull, bent or damaged nMAKE nDO BE AWARE of where your fingers are in relation to the drill bit SURE bit is centered in chuck and tightened before operating the drill NOT leave chuck key in chuck while operating machine nUSE A CLAMP when drilling metal, this will help prevent the material from spinning into your body or hand nNEVER hold metal in your bare hand while drilling nNEVER turn the drill press “on” before clearing the table of all objects (tools, scrap pieces, etc.) nDO NOT USE DRILL BITS THAT HAVE A SCREW TIP(called wood boring bits). At drill press speeds, they will bore into the wood so rapidly as to lift the work off the table and spin it. This can be very dangerous!!! nSEE nDO CHART BELOW for identification of drill bits NOT start the drill press with the drill bit in contact with the work piece nALWAYS let the drill chuck come to a complete stop on its own. Never grasp the chuck in an attempt to stop the drill bit nAVOID awkward hand positions where a sudden slip could cause a hand to move into the drill bit or cutting tool nDO NOT ATTEMPT to drill material that does not have a flat surface, unless a suitable support is used McIntire Department of Art, University of Virginia P.O. Box 400130, Charlottesville, VA 22904 Last Modified: April 2014 1 McIntire Department of Art safety procedures nTO PREVENT ROTATION OF THE WORKPIECE, ALWAYS clamp work securely to the table if it is too short to contact the column or when using a hole saw or cutting tools larger than 1/2” diameter nNEVER nDO work on the drill press table while the drill is operating NOT wear gloves, neckties, or loose clothing when operating the drill press nREFER to instruction manual for further information (see Studio Technician) Always use appropriate PPE for this machine Head/Face or Eye REQUIRED: clear face shield, safety glasses or goggles Clothing REQUIRED: long sleeves rolled up RECOMMENDED: long pants Hands No PPE needed. Do not wear gloves as they can get caught in moving parts Clear face shield Feet REQUIRED: shoes or boots. NO open-toed shoes, slip-ons, or high heels allowed in the shops Ears RECOMMENDED: ear plugs or ear muffs (general shop noise Respirator None needed unless drilling generates large amounts of dust. RECOMMENDED: N95 Safety glasses or goggles Respirator McIntire Department of Art, University of Virginia P.O. Box 400130, Charlottesville, VA 22904 Last Modified: April 2014 2 McIntire Department of Art safety procedures McIntire Department of Art, University of Virginia P.O. Box 400130, Charlottesville, VA 22904 Last Modified: April 2014 3 McIntire Department of Art safety procedures Other things to remember nThe shop has two drill presses. One in the wood shop and another in the metal shop. Please do not drill metal on the wood shop drill press nRemember to re-tighten the table lock lever before using the drill nAlways check the drill press speed chart to determine correct combination of material, bit size, and drilling speed nInsert drill bits about 3/4” (and at least 1/4”) into the chuck and tighten securely with the chuck key nThe chart is located on the wall behind the drill press nFactors which determine the best speed: nKind of material being worked (metal, acrylic, aluminum, wood, etc.) nSize of hole nType of drill bit (see pictures below) nQuality of cut desired nTypically, the smaller the drill bit, the greater the required RPM nIn soft materials, the speed should be higher than for hard materials nTo drill a through hole without splintering the bottom face, place the material on a scrap piece of wood. This also protects the point of the drill bit n!!!IMPORTANT!!! Use a scrap piece of wood to also prevent drilling into the metal table surface nSetting the depth stop can also avoid this problem. Drilling into the table not only dam- ages the table, but also the drill bits nTo prevent rotation of the work piece, clamp the work secure to the table, either with a “C” clamp or the drill press clamp nWhen using paddle/spade drill bits, you should always use a hold down clamp nPaddle bits are not to be used on metal nWhen drilling into metal, a cutting lubricant should be used. Cast iron and brass/bronze should be drilled dry nReturn bits to drawer when you are done and clean the area around the press McIntire Department of Art, University of Virginia P.O. Box 400130, Charlottesville, VA 22904 Last Modified: April 2014 4 McIntire Department of Art safety procedures Various Drill Bits Auger Bit nUse with hand drill only nDo not use on metal Paddle/Spade Bit nEasier to use larger diameter bits on drill press, but hand drills can be used nDo not use on metal Wood-boring Bit nUse with hand drill only nDo not use on metal Twist Bit with pilot tip nUse with drill press or hand drill nDo not use on metal Twist Bit nUse with drill press or hand drill nGreat for metal (use carbide tipped) nCarbide tipped bits are usually black Masonry Bit nUse with hammer drill only nUse only on masonry or plaster nNote the “hammerhead” tip nDo not use on metal McIntire Department of Art, University of Virginia P.O. Box 400130, Charlottesville, VA 22904 Last Modified: April 2014 5