Foreign Competition and Domestic Innovation: Evidence from U.S.

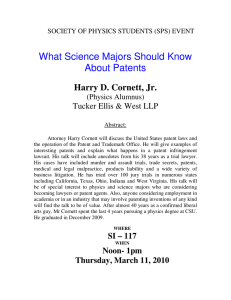

advertisement