An insight into modern manufacturing

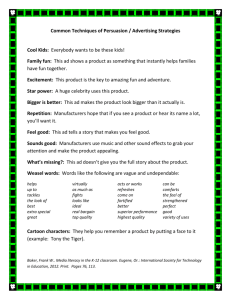

advertisement