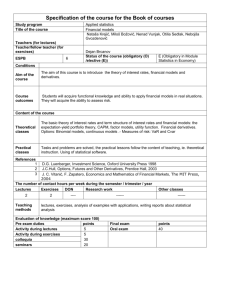

Master`s Programme in Mechanical Engineering – Course descriptions

advertisement