Unbrako Engineering Guide

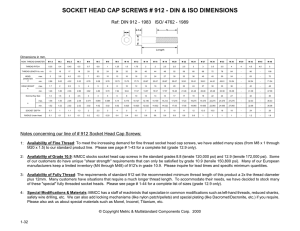

advertisement