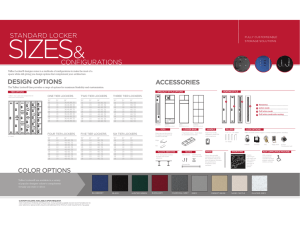

locker specifiers` guide

advertisement