California Institute of Technology

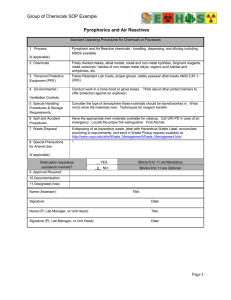

advertisement