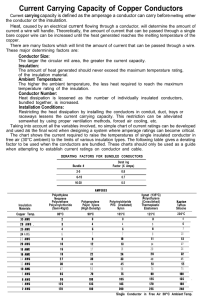

industrial and mining grade cables

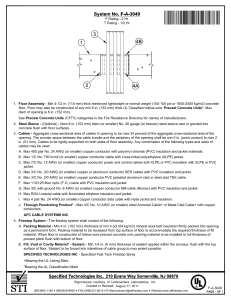

advertisement