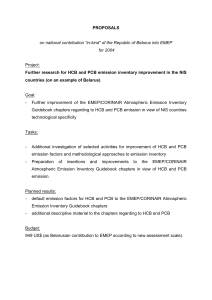

Danish emission inventory for hexachlorobenzene and

advertisement