MODEL 3641 Interlock Slide MODEL 3642 Companion Slide

advertisement

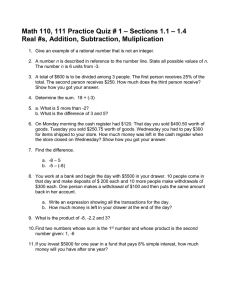

MODEL 3641 Interlock Slide mODEL 3642 Companion Slide Applications: For lateral files and heavy-duty multi-drawer cabinets where an interlock/anti-tilt system is required. For drawer heights greater than 3.5 inches. This product is covered by U.S. (5,757,109, 6,296,332) and various foreign patents issued and/or pending. Rod-Based Interlock System 180 lb.** [82 kg.] Capacity Closed Position MODEL 3641 .065±.005 [1.7±0.1] Gap (2x) 4.05 [102.9] .89 [22.6] .065±.005 [1.7±0.1] Gap (2x) Inches [mm] .75 [19.1] A .375 x .500 [9.5 x 12.7] Cut-Out MODEL 3642 .50 DIA. [12.7] .375 [9.5] 4.00 [101.6] .375 x .500 [9.5 x 12.7] Cut-Out B right electro-zinc (C) or black zinc (CB) B plating available Lengths ven lengths 14"–28", plus 17" E [353 mm–709 mm, plus 429 mm] Travel See Chart Height .09" [53.1 mm] (slide only); 3.50" ± .010 2 [88.9 mm ± 0.25] minimum spacing between slide center lines Load 180 lbs. [82 kgs.] per pair ** Side Space Hardware Also .89" (+ .030 / - .000) [22.6 mm (+ .76 / -0.00)] C'Sunk Slot for #10 x 82° Flat Head .286 x .380 Screw [7.3 x 9.7] (2x) .270 [6.9] DIA. .45 [11.4] G 1.38 [35.1] C'Sunk Hole for 6mm Dia. x 10mm Long Euro-Screw C'Sunk Hole for #10 x 82° Flat Head Screw .50 [12.7] TYP. H Slide Length Slide Length * Access provided to these holes in the closed position. 4.05 [102.9] A .75 [19.0] REF. Finish Mounting 2.52 [64.0] B .180 x .210 [4.6 x 5.3] .89 [22.6] * .375 [9.5] 4.00 [101.6] 2.09 [53.1] .250 DIA. [6.4] (2x) .50 DIA. [12.7] .180 x .210 [4.6 x 5.3] 1.50-2.00 [38.1-50.8] REF. .820 [20.8] (2x) Slide Travel ± .13 [3.3] 2.09 [53.1] .75 [19.1] .90 [22.9] REF. G 2.52 [64.0] 1.38 [35.1] .250 DIA. [6.4] (2x) * H .270 DIA. [6.9] .286 x .380 [7.3 x 9.7] TYP. C'Sunk Slot for #10 x 82° Flat Head Screw .45 [11.4] .50 [12.7] TYP. C'Sunk Hole for #10 x 82° Flat Head Screw C'Sunk Hole for 6mm Dia. x 10 mm Long Euro Screw Part Number Slide Length Slide Travel Pocket A Pocket B Hole G Hole H 3641-14 3642-14 13.90 [353] 14.00 [356] 1.80 [45.7] 8.50 [215.9] 8.82 [224.0] - 3641-16 3642-16 15.90 [404] 17.00 [432] 1.80 [45.7] 10.50 [266.7] 8.82 [224.0] 12.60 [320.0] 3641-17 3642-17 16.90 [429] 18.00 [457] 1.80 [45.7] 10.50 [266.7] 8.82 [224.0] 12.60 [320.0] 3641-18 3642-18 17.90 [455] 19.00 [483] 1.80 [45.7] 10.50 [266.7] 8.82 [224.0] 13.86 [352.0] abinet: Traditional (#10 flat head screws) or C 32 mm system (Euro) screws Drawer: Adapter bracket (#8 screws) 3641-20 3642-20 19.90 [505] 21.00 [533] 2.80 [71.1] 10.50 [266.7] 8.82 [224.0] 16.38 [416.0] 3641-22 3642-22 21.90 [556] 23.00 [584] 2.80 [71.1] 12.50 [317.5] 12.60 [320.0] 16.38 [416.0] 10 x 82° flat head or 6 mm DIA. x 10 mm long # Euro screw 3641-24 3642-24 23.90 [607] 25.00 [635] 2.80 [71.1] 12.50 [317.5] 12.60 [320.0] 18.90 [480.0] isconnect using drawer adapter bracket. D Sequencing latch, silenced open and close, detent closed 3641-26 3642-26 25.90 [658] 27.00 [686] 2.80 [71.1] 15.50 [393.7] 12.60 [320.0] 21.42 [544.0] 3641-28 3642-28 27.90 [709] 29.00 [737] 2.80 [71.1] 15.50 [393.7] 12.60 [320.0] 23.94 [608.0] ** Load rating based on an 18" slide on a 42" wide drawer cycled 75,000 times. 2 Installation Instructions Cabinet Mounting Instructions Traditional Mounting Install cabinet members using #10 x 82° flat head screws. Refer to Figure 1 for cabinet hole locations. Be sure slides are parallel. Front of slide is set flush with cabinet front for overlay drawer fronts. Install screws in second hole (horizontal slot) and rear most horizontal slot. OTE: N Due to the heavy load capability and limitations of screw retention in wood products, Accuride recommends the use of two #10 screws, 3/4" long, at the front of the cabinet member and at least one at the rear. Traditional Mounting Figure 1 Front See 1.88* Pilot hole for #10 screw (TYP.) Page 2.52 Increase by 1/2" (12.7 mm) when using Timberline #AC610 actuator–plus–thickness of drawer front on inset applications. Access provided in closed position *For inset drawers #10 x 82° flat add front thickness head screw (TYP.) -OR- Figure 2 32 mm Mounting 32 mm System Other members omitted for clarity Install cabinet members using 6 mm x 10 mm Euro screws. Refer to Figure 2 for cabinet hole locations. Be sure slides are parallel. CAUTION: USE ONLY FLAT HEAD SCREWS FOR MOUNTING CABINET MEMBER! age ront P 5 mm pilot holes See F 37.0 64.0 Connecting Rod Recommendations Connecting rod length is determined by the center line measurement between adjacent slide cabinet members. See L in Figure 3. From that dimension subtract 2". That becomes the rod length. Rod length should be held to ± .020. Steel or aluminum is the recommended rod material. Rod diameter is 1/4" (.250"). See Figure 4. Access provided in closed position 6 mm x 10 mm Euro screw (TYP.) Connecting Rods for Bulk and Distributor Orders For bulk orders, customers can supply their own connecting rods or purchase aluminum connecting rods directly from Accuride. See ordering instructions on back page. Figure 3 For Distributor X-Pack orders, Accuride supplies two 12" aluminum connecting rods. The rods can be cut to length as required. Maintaining ± .020 tolerance is critical to achieve optimum performance. Installation of Connecting Rods Insert the rod into the upper follower rod pocket of the lower slide. Rotate the rod toward the lower follower rod pocket of the upper slide. Once located, snap the rod into position. See Figure 3. Repeat for all slides mounted into the cabinet. L Figure 4 .250" Diameter Rod Length ± .020 L - 2.00" = Rod Length Installation Instructions 3 Drawer Mounting Instructions Figure 5 Drawer Sizes The bracket system will accommodate drawer heights 3.50" (89 mm) or greater and widths to 42". Wood Drawer Refer to Figure 5 for front and rear mounting bracket hole locations and install screws through vertical slots. Drawer mounting holes should be placed on a line 1.38" above slide center line, with the first hole located .31" plus Pocket "A" dimension (see chart on front page) behind drawer front. Extend the slides fully forward. Mount drawer slide by lowering the rear bracket tabs through the rear slide pocket (see Figure 6). Lower drawer until front bracket tabs snap into front pockets. ♦ Becomes A + .31" [7.9 mm] when using Timberline #AC610 actuator. 14" 16"–20" 22"–24" 26"–28" J - 8.50" - 10.50" 7.00" 12.50" 8.50" 15.50" 2.00 [50.8] TYP. 1.00 [25.4] TYP. .31 [7.9] 1.00 REF. [25.4] 1.50 [38.1] .171 x .297 [4.3 x 7.5] (2x) .177 DIA. [4.5] (4x) .180 DIA. [4.6] (2x) .180 x .406 [4.6 x 10.3] (2x) 2.15 [54.6] .19 [4.8] .72 [18.3] K .19 [4.8] .78 [19.8] REF. H Figure 6 Drawer Adapter Bracket r Fron t ♦ A + .31" [7.9] Drawe NOTE: To remove, lift drawer up and outward. Drawer can be permanently fixed to the cabinet using a screw through the front pocket hole, or bending the locking tab. Drawer Adapter Brackets Part Number H 5430-1216-CL 10.00" 5430-1216-CR 5430-1720-CL 12.00" 5430-1720-CR 5430-2124-CL 14.00" 5430-2124-CR 5430-2528-CL 17.00" 5430-2528-CR J 1.00 [25.4] TYP. .39 [9.9] Close drawer fully to locate horizontal slide position in cabinet. Open drawer to adjust and install remaining screws. Secure brackets after adjusting the drawer vertically and horizontally. Slide Length Drawer Member Adapter Bracket 1.38" [3 5.1] Slide Ce nterline K Figure 7 Slide Metal Drawer .065" Drawer Cut-Out Recommendations Cut-out recommendations are based on 16 gauge material thickness. See Figure 7. For B dimension, see table on front. If a thinner material is used, adjustments to the cut-outs must be made to ensure a proper fit. Refer to the table below for the required modifications if 16–22 gauge material is used. 4.00" Material Thickness D E 16 .060 [1.52] .855 [21.7] .815 [20.7] 18 .048 [1.22] .865 [22.0] .825 [21.0] 20 .036 [.91] .885 [22.5] .845 [21.4] 22 .030 [.76] .905 [23.0] .865 [22.0] Mounting Slide to Drawer Using recommended placement of drawer bayonets (see Figure 8), extend both right and left hand slide drawer members. See Figure 9. Position rear drawer tabs into both rear slide pockets. Guide front tabs into front pockets and push firmly into place making sure drawer lug snaps into cut-out on slide drawer member. See Figure 9. For optimum slide performance, it is recommended that the slide centerline be located at the center line of the drawer side, or slightly toward the plane of the drawer pull. [1.7] B ] [101.6 Figure 8 D Material Gauge rline Cente .90 [22.9] 1.25 [31.8] .38 [9.7] .06 x 45° [1.5 x 45°] .16 [4.1] (4x) Figure 9 * Overlay applications: .13" [3.3] * Inset applications: .13" [3.3] -- plus -- drawer front thickness * Add 1/2" (12.7) to each when using Timberline AC610 .20 [5.1] .32 [8.1] CL .45 [11.4] E Specifications Guidelines Ordering Instructions Side Space Interlock and Companion Slides Slides are unhanded and ordered as each. Complete your slide order for Accuride model 3641 interlock slide and model 3642 non-locking companion slide by specifying as follows: 100 Each C 3641 -16 100 Each C 3642 -16 Total Slides Required Slide Finish* Model 3641 Interlock Slide Model 3642 Non-Locking Companion Slide Slide Length * "C" for bright zinc, "CB" for black zinc The basic slide assembly functions best in the following operating space: Metal applications: Wood applications: .75" + .030 / - .000 [3/4" + 1/32" / - 0] .89" + .030 / - .000 [7/8" + 1/32" / - 0] Interlock Strength The interlock system is designed to resist 200 pound pull on a blocked drawer (force applied to unopened drawer with one drawer already open). Rods of sufficient stiffness must be used to ensure this capability. Self-Closing It is common practice on file cabinets to mount the slides with a slight backslope to compensate for cabinet tilting. Limit this angle to 1° for best interlock rod action. Spring Load Some gang lock interface devices may apply a download on the rod stack. Also, some systems may use a spring-load on the rod stack to achieve a self-closing action for the last 1/2" of closure travel. Optimum cycle life requires this spring load be limited to 5 lbs. Cabinet Security Locks The interlock system can be used to lock all drawers in the cabinet. An interface device can be applied above the rod stack to simulate the action of an open drawer on existing cabinet designs. A simple cam mechanism can be designed to block the rod stack, driven by the current key lock. A device directly actuated by a lock cylinder cam is available from Accuride (order kit #4180-0345-XE), or directly from Timberline* (#AC610). Similarly, an actuator driven by a flexible shaft from a center mounted key lock is also available from Timberline by ordering part number #AC600. Gang Locking System For optional gang locking system, order kit P/N 4180-0345-XE. For lock on left or right hand side, order 1 kit per unit. For lock on both sides, order 2 kits per unit. Kit 4180-0345-XE contains: 1 Each 2999-9436-YE (Timberline #AC610) 1 Each Installation Sheet Accuride P/N 4180-0345-XE (Timberline P/N AC610) Length of 1/4" diameter steel or aluminum 1.61 [40.9] 2.87 [72.9] Rod = X - 1/8" [3.2] ± .020 1.61 [40.9] With bracket for direct actuation by eccentric lock Centerline of top slide X Dimensions and features are controlled by Timberline. Subject to change at Timberline's discretion. Timberline Supply, Ltd. Lake Bluff, IL 60044 (800) 562-5227 Timberline P/N AC600 4 Adapter Brackets The adapter brackets are handed. Order one left hand (CL) and one right hand (CR) bracket per pair of slides. For part numbers, refer to the chart on page 3. Complete your order for the adapter brackets by specifying as follows: 100 each 5430-1720 -B L 100 Each 5430-1720 -C R Total Brackets Required Bracket Part Number Bracket Finish* Bracket Hand** * "C" for bright electro-zinc, "B" for black zinc ** "L" for left hand, "R" for right hand Connecting Rods Aluminium connecting rods are available in bulk and ordered separately. When using the gang locking system, order 1 rod for each drawer (5 drawers = 5 rods). For interlock function only, order 1 rod for each drawer minus 1 (5 drawers minus 1 = 4 rods). Complete your rod order by specifying as follows: 400 Each 2999-9435-YE Total Rods Required Rod Part Number Packaging Instructions Bulk Pack: Model 3641 Lengths 14"–22" 10 ea/box Lengths 24"–28" 5 ea/box Model 3642 All Lengths 10 ea/box Adapter brackets and connecting rods ordered separately. (X) Pack: All lengths 2 pr/box Each box contains: 2.87 [72.9] Flexible steel shaft from center mounted lock cylinder 2 Each Interlock Slides (C3641-XX) 2 Each Non-Locking Companion Slides (C3642-XX) 2 Pair Adapter Brackets (5430-XXXX-CL/CR) 2 Each 12" Connecting Rods (2999-9435-YE) 1 Each Mounting Screws 1 Each Installation Sheet Centerline of top slide X Specifications Slide members and ball retainers: Cold rolled steel Ball bearings: Acetal polymer and carburized steel RoHs Compliant Note: Specifications, materials, prices, terms, and delivery are subject to change without notice. For the most current technical information visit www.accuride.com ACCURIDE INTERNATIONAL INC. 12311 Shoemaker Avenue Santa Fe Springs, CA 90670 TEL (562) 903-0200 FAX (562) 903-0208 www.accuride.com Manufacturing, Engineering, and Sales United States • Germany • Japan • Mexico • United Kingdom • China Copyright © 2007 Accuride International Inc. 3700-9398(1065)-MK054-R8-0213