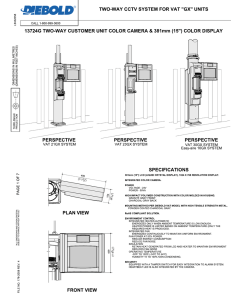

PLAN VIEW FRONT ELEVATION SIDE ELEVATION CONSUMER

advertisement

fi OPTEVA R L596 WITH 13mm 1 (2") SHORT SAFE CALL 1-800-999-3600 CONSULT WITH DIEBOLD INSTALLATION/SERVICE BRANCH FOR ADDITIONAL DETAILS AND INFORMATION. ( DI M ENSI ONS I NI NCHES) PLEASE SEE PLANNING AND SITE PREPARATION GUIDE TP-820716-001. 794 1 (31 4") 13 13 1 ( 2") ( 2") 1 768 1 CONSUMER ACCESS DIMENSIONS 11 16" ) 5 ( 35 906 795 (30 4") ( 31 16" ) A 1 3 794 ( 4 8" ) 111 THI RD ANGLE PROJECTI ON B TOP OF MONITOR TOP FUNCTION KEY HEIGHT DEPTH 1161mm 198mm 13 16") (451116") (7 1077mm 146mm (4238") (534") 111mm 878mm C RECEIPT PRINTER D ADVANCED FUNCTION DISPENSER E CARD READER (438") 9 16") (34 0 ( 0") 688mm (27116") (31 4") PLAN VIEW 111mm 878mm (438") (34916") PAGE 1 OF 4 HEIGHT - FROM BOTTOM OF SAFE DEPTH - FROM FRONT EDGE OF BEZEL 906 111 11 16") (35 3 (4 8") 794 9 3 (9 8") 3 (4 8") 906 11 16") (35 SIDE ELEVATION 11 16" ) ( 58 1490 15 16" ) ( 57 1471 5 111 FRONT ELEVATION 5 795 11 16" ) 1490 11 ( 58 16" ) 1490 795 (31 16") 0m m TO 76m m ( 0"TO 3" )LEVELI NG OPTIONAL CONSUMER BAR CODE SCANNER (SEE "CAUTION" LABEL ON PAGE 2 OF 4) 676 D 15 ( 57 16" ) C 0m m TO 76m m ( 0"TO 3" )LEVELI NG E B ( 31 16" ) 3 ( 4" ) 19 3 (13 8") A 1471 " ALL DI M ENSI ONS AND DESI GN CRI TERI A SUBJECT TO CHANGE W I THOUT NOTI CE" 238 3 (12 4") (8 16") FI LE NO.177474 REV.4 340 5 1 (18 2") 19 217 3 5 324 ( 26 8" ) 470 (31 16") ( 4" ) 795 1 (31 4") ( 58 DI M ENSI ONS I N MI LLI M ETRES 720 ADVANCED FUNCTION LOBBY ATM FRONT LOAD - 4 HIGH CONDUIT AND JUNCTION BOX REQUIREMENTS POWER REQUIREMENTS: THE ATM REQUIRES A SINGLE-PHASE, THREE-WIRE UNSWITCHED POWER RECEPTACLE. 25mm (1") METAL CONDUIT FROM ALARM CONTROL CABINET JUNCTION BOX TO 102mm (4") SQ. X 54mm 1 (218") WIRING TO THE RECEPTACLE MUST INCLUDE A THIRD-WIRE EARTH GROUND (CONDUIT DEEP JUNCTI0N GROUND IS NOT ACCEPTABLE). THE ATM WILL PROVIDE A POWER CORD WITH A COUNTRY BOX (ALL BY OWNER’S E.C.). DIEBOLD TO PROVIDE FLAT COVER SPECIFIC POWER PLUG. THE POWER SUPPLIED MUST BE AS SPECIFIED BELOW. WITH TAMPER SWITCH. 100-127 VAC (+6%, -10%) AT 50 (–1%) Hz, SINGLE-PHASE 2 WHEN "SECUROMATIC" AFTER HOUR DEPOSITORY IS TO BE CONNECTED TO 100-127 VAC (+6%, -10%) AT 60 (–1%) Hz, SINGLE-PHASE CASH DISPENSER, OWNER’S E.C. TO RUN 19mm 3 (4") METAL CONDUIT FROM 200-240 VAC (–10%) AT 50 (–1%) Hz, SINGLE-PHASE 200-240 VAC (–10%) AT 50 (–1%) Hz, SINGLE-PHASE 102mm (4") S.Q. X 54mm (218") DP. JUNCTION BOX TO AFTER HOUR DEPOSITORY. POWER TO THE ATM IS TO BE A DEDICATED SERVICE AND MUST BE PROTECTED BY A 3 OWNER’S E.C. TO RUN 19mm 3 (4") LIQUID TIGHT FLEX METAL CONDUIT OR 19mm 3 (4") SAFETY QUICK-DISCONNECT DEVICE TO BREAK LINE VOLTAGE (SUCH AS A CIRCUIT BREAKER AT THE ELECTRICAL SERVICE PANEL. THE QUICK-DISCONNECT DEVICE RIGID CONDUIT FROM JUNCTION BOX TO CABLE CONNECTION PLATE. (OR CIRCUIT BREAKER) MUST TURN OFF THE LINE VOLTAGE AT THE FOLLOWING AMPERAGE. 3 19mm ( 4") METAL CONDUIT AND UNSWITCHED ELECTRICAL SUPPLY TO ( DI M ENSI ONS I NI NCHES) DI M ENSI ONS I N MI LLI M ETRES 4 100-127 VAC (+6%, -10%) SERVICE, DISCONNECT AT 20 AMPERES 102mm (4") SQ. X 54mm (218") DEEP JUNCTION BOX WITH RECEPTACLE 200-240 VAC (–10%) SERVICE, DISCONNECT AT 10 AMPERES WITHIN 2210mm (87") OF SIDE CONNECTING PLATE. BOTTOM CONNECTION THE MODULE BULK POWER SUPPLY AND PROCESSOR POWER SUPPLY WILL PROVIDE MUST BE COMPENSATED ACCORDINGLY (ALL BY OWNER’S E.C.) POWER CONDITIONING TO PREVENT THE TERMINAL FROM MALFUNCTIONING DUE TO (SEE POWER REQUIREMENTS). 5 SHORT-TERM AC POWER FLUCTUATIONS AS OUTLINED IN EN61000-4-11. POWER USAGE: OWNER’S E.C. TO SUPPLY COMPATIBLE RECEPTACLE FOR COUNTRY SPECIFIC PLUG-IN CONNECTOR SUPPLIED WITH UNIT. POWER CORD 1 2 190 WATTS 229 WATTS 285 WATTS 349 WATTS 550 WATTS 614 WATTS MACHINE STATUS LENGTH 2184mm (86") FROM SIDE OF UNIT. IDLE (NO TRANSACTION) NOTE: TRANSACTION (DISPENSE JUNCTION BOXES MUST BE LOCATED WITHIN 2210mm (87") OF CONNECTING PLATE. (LENGTH OF ELECTRICAL POWER CABLE OR BULK NOTE) IN PROGRESS PROVIDED WITH UNIT). LOCATE IN AN EASILY ACCESSIBLE AREA. RAPID PROCESSING TRANSACTION IN PROGRESS BOXES CAN BE FLUSH MOUNTED WITH CONCEALED CONDUIT FOR NEW CONSTRUCTION OR BOXES CAN BE SURFACE MOUNTED WITH CONFIGURATION: EXPOSED CONDUIT FOR EXISTING CONSTRUCTION. PHYSICAL SECURITY THE SECURITY SAFE MEETS THE BANK PROTECTION ACT 82 STAT 295, 1 PROCESSOR, COLOR LCD CONSUMER DISPLAY, MOTORIZED CARD READER, JOURNAL 2 PROCESSOR, SVD LCD CONSUMER DISPLAY, MOTORIZED CARD READER, JOURNAL PRINTER, PRINTER, 80mm THERMAL RECEIPT PRINTER, STANDARD DEPOSITORY AND 5 HIGH AFD. 80mm THERMAL RECEIPT PRINTER, IDM, 5 HIGH AFD, AND BULK NOTE ACCEPTOR. 12 USC 882, AND MEETS THE ATTACK TEST PER UL 291-15. THE SAFE DOOR RAPID PROCESSING - SYSTEMS CONFIGURED FOR SIMULTANEOUS IDM (INTELLIGENT HAS A POSITIVE RELOCKING FEATURE. THE SAFE DOOR IS CONTROLLED BY A DEPOSITORY MODULE) AND ENA (ENHANCED NOTE ACCEPTOR) OR IDM AND BNA (BULK GROUP 2 COMBINATION LOCK WITH OR WITHOUT KEYLOCKING DIAL CAPABILITY NOTE ACCEPTOR) OPERATIONS. OR OPTIONAL ELECTRONIC LOCK. THE POWER USE DEPENDS ON THE NUMBER AND TYPE OF DEVICES PRESENT IN ALARM PROTECTION THE ATM, AND THE TYPE OF TRANSACTION THE ATM IS PERFORMING. THE UL-LISTED SAFE IS EQUIPPED WITH A BASIC ALARM SENSOR PACKAGE. THE HEAT OUTPUT CONFIGURATION: BASIC PACKAGE INCLUDES A SAFE DOOR OPEN SWITCH, ALARM SHUNTING SWITCH, PROJECTI ON 1 971 BTU/HR DISPENSING 648 BTU/HR IDLE 1,875 BTU/HR RAPID PROCESSING SIGNAL CABLE RUN CONSTRAINTS 2 THE FOLLOWING CHART ITEMIZES THE PHYSICAL SPACING REQUIREMENTS OF THE SIGNAL CABLE RUN WITH RESPECT TO OTHER POWER AND ELECTRICAL EQUIPMENT CABLE RUN. 1,190 BTU/HR BULK NOTE ACCEPTING 781 BTU/HR IDLE 2,094 BTU/HR RAPID PROCESSING OPERATING ENVIRONMENT: SAFE LOCATION 10” C TO 38” C (50” F TO 100” F) RELATIVE HUMIDITY (NON-CONDENSING) SEPARATION FROM OTHER CABLES TYPE OF ELECTRICAL RUN BELOW 2 KVA FLUORESCENT, NEON OR INCANDESCENT 20 TO 80% AT 32” C (90” F), 20 TO 55% AT 38” C (100” F) ABOVE 5 KVA 2-5 KVA WEIGHT OF UNIT: 127mm (5") 127mm (5") 127mm (5") 305mm (1’-0") 610mm (2’-0") 64mm (212") 152mm (6") 305mm (1’-0") LIGHTING FIXTURES UNSHIELDED POWER LINE OR 644 kg (1,420 LBS.) 127mm (5") ELECTRICAL EQUIPMENT CAUTION LABEL UNSHIELDED POWER LINES OR ELECTRICAL EQUIPMENT WITH SIGNAL CABLES ENCLOSED IN GROUNDED CONDUIT POWER LINES IN GROUNDED CONDUIT WITH SIGNAL CABLES IN GROUNDED 30mm (1316") 76mm (3") 152mm (6") SIGNAL CABLE INSTALLATION CONSTRAINTS: RELATIVE CARE IS REQUIRED WHEN INSTALLING SIGNAL CABLES IN CONDUITS, UNLIKE POWER AND LIGHTING CABLE, SIGNAL CABLES HAVE CONDUCTORS AND LIGHT INSULATION AND WILL NOT WITHSTAND AS MUCH STRAIN IN INSTALLATION. 11 16") (2 906 651 11 16") 1 ( 1 16" ) 240 339 7 (9 16") (13 16") 5 1 39 (35 ( 1 2" ) 19 3 ( 4" ) 27 5 (25 8") 5 ( 40 8" ) 1032 5 1405 15 16" ) 1471 ( 57 5 1490 ( 58 8" ) 1 0m m TO 76m m ( 0"TO 3" )LEVELI NG " ALL DI M ENSI ONS AND DESI GN CRI TERI A SUBJECT TO CHANGE W I THOUT NOTI CE" 68 75 15 (2 16") ( 55 16" ) PAGE 2 OF 4 CONDUIT FI LE NO.177474 REV.4 THI RD ANGLE AND RATE-OF-RISE HEAT SENSOR. 4 2 4 1 5 3 POWER CORD 378 768 1 13 (30 4") 1 1 ( 2") 13 794 ( 2") 1 (31 4") BACK ELEVATION NOTE: BACK PANEL DESIGN ON EARLIER VERSIONS OF THIS OPTEVA MODEL MAY DIFFER FROM THE BACK ELEVATION AS SHOWN 379 7 15 16") (14 8") (14 38 1 (1 2") 795 5 (31 16") SIDE ELEVATION OPTEVA fi 720 ADVANCED FUNCTION LOBBY ATM FRONT LOAD - 4 HIGH R WITH 13mm 1 (2") SHORT SAFE CALL 1-800-999-3600 NOTE: SHOWN IS THE MINIMUM/RECOMMENDED AREA REQUIRED FOR INSTALLATION AND SERVICE. DIMENSIONS SHOWN MAY BE INCREASED WHEREVER POSSIBLE TO IMPROVE INSTALLATION AND SERVICE ACCESS. USE OF ANY AREA LESS THAN THE RECOMMENDED AREA MAY RESULT IN AN INCREASE IN INSTALLATION AND SERVICE TIME. CONSULT WITH DIEBOLD INSTALLATION/SERVICE BRANCH FOR SPECIAL BUILDING CONDITIONS. RECOMMENDED SERVICE AREA MINIMUM SERVICE AREA ALL ELECTRICAL AND DATA CABLES MUST ENTER UNIT IN THIS AREA 1 794 1 ( 6" ) 5 321 ( 12 8" ) 152 1 51 51 (2") (2") (11 4") ( 17 16" ) 433 1 (31 4") 9 ( 38 16" ) 9 1208 ( 47 16" ) 979 1 1 ( 76 4" ) 1936 11 16" ) 51 (2") 285 1 (6 4") 51 51 794 3 (11 4") 906 5 ( 12 8" ) ( 6" ) 321 152 1 ( 17 16" ) 11 16" ) 1 (31 4") (2") 171 ( 35 433 51 ( 2" ) 285 ( 35 3 (6 4") 906 (49 4") ( 2" ) 171 2165 ( DI M ENSI ONS I NI NCHES) PROJECTI ON 1250 1 ( 85 4" ) DI M ENSI ONS I N MI LLI M ETRES THI RD ANGLE 1250 (49 4") PLAN VIEW-SINGLE UNIT (MINIMUM SERVICE AREA) PLAN VIEW-SINGLE UNIT PAGE 3 OF 4 (RECOMMENDED SERVICE AREA) 3180 3 (125 16") 965 965 3 (38") (38") (22 8") 171 794 3 1 5 ( 12 8" ) ( 6" ) 51 51 (2") (2") 3 (6 4") 794 1 (31 4") 171 3 (6 4") 1 ( 17 16" ) 321 (31 4") 171 9 ( 38 16" ) 979 1 1936 433 152 11 16" ) ( 35 51 906 ( 2" ) (6 4") ( 76 4" ) " ALL DI M ENSI ONS AND DESI GN CRI TERI A SUBJECT TO CHANGE W I THOUT NOTI CE" FI LE NO.177474 REV.4 568 PLAN ADJACENT UNITS (MINIMUM SERVICE AREA) 682 13 16") (26 794 1 (31 4") 285 1 (11 4") 411 7 1 7 98 ( 3 8" ) ELECTRICAL AND DATA CABLING ENTERS THE ATM THROUGH A CABLE ENTRY OPENING ON THE SIDE OF THE SAFE. CABLES ENTERING THE CASH DISPENSER PASS THROUGH THE POWER CABLE PLATE WHICH IS ATTACHED TO THE INSIDE WALL OF THE SAFE OVER THE CABLE ENTRY OPENING. CABLING CAN ENTER FROM THE SIDE OR OPTIONALLY FROM UNDER THE CASH DISPENSER. THE CABLE ENTRY OPENING IS ON THE LEFT SIDE OF THE SAFE AS VIEWED FROM THE FRONT OF THE CASH DISPENSER. 5 795 SAFE ( 31 16" ) 9 598 ( 23 16" ) 3 400 ALARM CABLES (SIDE ENTRY) 3 35 29mm (118") DIA. HOLE FOR ( 1 8" ) 15 16" ) OPENING FOR POWER CORD AND DATA CABLES (SIDE ENTRY) 2 1 7 1 175 2 ( 6 8" ) ( 14 ( 15 4" ) 1 CABLE ENTRY OPENING (SEE NOTE) 379 38 CABLE ENTRY NOTE: 2 ( 1 2" ) ( DI M ENSI ONS I NI NCHES) 2 DI M ENSI ONS I N MI LLI M ETRES 220 1 11 16" ) (12 8") 7 378 ( 14 8" ) 327 3 (16 16") ( 8 30 3 (1 16") 35 698 35 3 (1 8") 1 (27 2") 3 (1 8") POWER CABLE PLATE 768 SAFE 1 PROJECTI ON PLAN/SECTION SAFE FLOOR 1-(4) 14mm (916") DIA. LEVELING LEG HOLES 2-(4) 25.4mm (1") DIA. FLOOR MOUNTING HOLES NOTES: FOR ADDED SECURITY: IT IS RECOMMENDED THAT THE ATM SAFE BE SECURED TO THE FLOOR WITH ANCHOR BOLTS. USE THE FOLLOWING GUIDELINES TO DETERMINE THE APPROPRIATE METHOD FOR YOUR INSTALLATION. ANCHORING THE ATM TO CONCRETE FLOORS: IT IS RECOMMENDED THAT THE ATM BE ANCHORED TO CONCRETE FLOORS WHENEVER POSSIBLE. DIEBOLD RECOMMENDS USING A M20 OR 19mm 3 (4") ANCHOR BOLT THAT IS 203mm (8") LONG. CONCRETE FLOORS OR CONCRETE BASES MUST BE A MINIMUM OF 102mm (4") THICK FOR ANCHORING TO BE EFFECTIVE. THERE IS NO LIMIT FOR MAXIMUM THICKNESS. ANCHOR BOLTS MUST BE USED IN ALL AVAILABLE ANCHOR HOLES. IF THE TERMINAL IS EQUIPPED WITH LEGS, THE LEVELING LEGS MUST BE REMOVED BEFORE THE TERMINAL IS ANCHORED. REFER TO VIEW "A" AND "B" FOR ADDITIONAL DETAILS. PAGE 4 OF 4 ANCHORING THE ATM TO WOOD FLOORING: ATM’S INSTALLED ON WOOD FLOORS OR FLOORS SUPPORTED BY WOODED BEAMS CAN BE SECURED BY A MACHINE-THREADED NUT AND BOLT METHOD. IT IS PREFERRED THAT THE HARDWARE BE ATTACHED THROUGH SUPPORTING POSTS OR BEAMS FOR MAXIMUM HOLDING CAPACITY. ADDITIONALLY, THIS HARDWARE MUST ATTACH TO A LOCALLY FABRICATED REINFORCEMENT PLATE INSTALLED UNDERNEATH THE FLOOR TO PROVIDE ADDITIONAL 1 STRENGTH. THE REINFORCEMENT PLATE IS TYPICALLY 6mm (4") THICK. IT IS IMPORTANT TO NOTE THAT THE OVERALL HOLDING CAPACITY OF A WOOD FLOOR WILL BE LESS THAN THAT OF CONCRETE FLOORS. ANCHORING THE ATM TO STEEL FLOORS: ATM’S INSTALLED ON STEEL FLOORS CAN BE SECURED BY A MACHINE-THREADED METHOD. IT IS PREFERABLE THAT THE HARDWARE BE ATTACHED THROUGH SUPPORTING POSTS OR BEAMS FOR MAXIMUM HOLDING CAPACITY. ADDITIONALLY, THIS HARDWARE MUST ATTACH TO A LOCALLY FABRICATED REINFORCEMENT PLATE INSTALLED UNDERNEATH THE FLOOR TO PROVIDE ADDITIONAL STRENGTH. THE COMBINED BACKING PLATE AND FLOOR THICKNESS MUST OWNER’S INSTALLER TO DRILL (4) 19mm 3 (4") DIA. X 203mm (8" MIN.) DEEP HOLES IN CONCRETE FLOOR (RECOMMENDED DRILLING COMPLETELY THROUGH FLOOR WHEN POSSIBLE AND TO BE SECURED TO THE CONCRETE FLOOR WITH (4) 3 19mm ( 4")-10 X 203mm (8") LONG WEDGE ANCHORS (SUPPLIED BY OWNER’S INSTALLER) VIEW "A" MINIMUM HOLE DEPTH 203mm (8") VIEW "B" MINIMUM CONCRETE DEPTH 102mm (4") ( 4" ) MI N. 102 PART NUMBER 282520). ( 8" ) DIEBOLD PART NUMBER 29-016376-000A, HILTI 203 M I N. " ALL DI M ENSI ONS AND DESI GN CRI TERI A SUBJECT TO CHANGE W I THOUT NOTI CE" BE AT LEAST 13mm 1 (2"). FI LE NO.177474 REV.4 THI RD ANGLE (30 4")