EvaluationandEfficiencyComparisonofFrontEndAC

advertisement

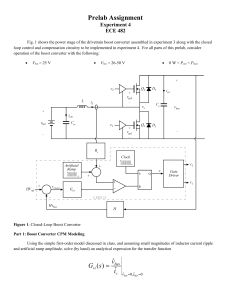

IEEE TRANSACTIONS ON SMART GRID, VOL. 3, NO. 1, MARCH 2012 413 Evaluation and Efficiency Comparison of Front End AC-DC Plug-in Hybrid Charger Topologies Fariborz Musavi, Member, IEEE, Murray Edington, Member, IEEE, Wilson Eberle, Member, IEEE, and William G. Dunford, Senior Member, IEEE Abstract—As a key component of a plug-in hybrid electric vehicle (PHEV) charger system, the front-end ac-dc converter must achieve high efficiency and power density. This paper presents a topology survey evaluating topologies for use in front end ac-dc converters for PHEV battery chargers. The topology survey is focused on several boost power factor corrected converters, which offer high efficiency, high power factor, high density, and low cost. Experimental results are presented and interpreted for five prototype converters, converting universal ac input voltage to 400 V dc. The results demonstrate that the phase shifted semi-bridgeless PFC boost converter is ideally suited for automotive level I residential charging applications in North America, where the typical supply is limited to 120 V and 1.44 kVA or 1.92 kVA. For automotive level II residential charging applications in North America and Europe the bridgeless interleaved PFC boost converter is an ideal topology candidate for typical supplies of 240 V, with power levels of 3.3 kW, 5 kW, and 6.6 kW. Index Terms—AC-DC power converters, DC-DC power converters, power conversion, power electronics, power quality. I. INTRODUCTION A PLUG-IN HYBRID electric vehicle (PHEV) is a hybrid vehicle with a battery electric storage system that can be recharged by connecting a plug to an external electric power source. The vehicle charging ac inlet requires an onboard ac-dc charger with power factor correction [1]. An onboard 3.4 kW charger can charge a depleted battery pack in PHEVs to 95% charge in about 4 h from a 240 V supply [2]. A variety of power architectures, circuit topologies, and control methods have been developed for PHEV battery chargers. However, due to large low frequency ripple in the output current, the single-stage ac-dc power conversion architecture is only suitable for lead acid batteries. Conversely, two-stage ac-dc/dc-dc power conversion provides inherent low frequency ripple rejection. Manuscript received February 26, 2011; revised July 26, 2011; accepted August 10, 2011. Date of publication October 20, 2011; date of current version February 23, 2012. This work was sponsored and supported by Delta-Q Technologies Corporation. Paper no. TSG-00078-2011. F. Musavi is with the Research Department, Delta-Q Technologies Corp., Burnaby, BC V5G 3H3 Canada (e-mail: fmusavi@delta-q.com). M. Edington is with the Engineering Department, Delta-Q Technologies Corp., Burnaby, BC V5G 3H3 Canada (e-mail: medington@delta-q.com). W. Eberle is with the School of Engineering, University of British Columbia/ Okanagan, Kelowna, BC V1V 1V7 Canada (e-mail: wilson.eberle@ubc.ca). W. G. Dunford is with the Department of Electrical and Computer Engineering, University of British Columbia, Vancouver, BC V6T 1Z4 Canada (e-mail: wgd@ece.ubc.ca). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TSG.2011.2166413 Fig. 1. Simplified block diagram of a universal battery charger. Therefore, the two-stage approach is preferred for PHEV battery chargers, where the power rating is relatively high, and lithium-ion batteries, requiring low voltage ripple, are used as the main energy storage system [3]. A simplified block diagram of a universal input two-stage battery charger used for PHEVs is illustrated in Fig. 1. The ac-dc plus PFC stage rectifies the input ac voltage and transfers it into a regulated intermediate dc link bus. At the same time, power factor correction is achieved [4]. The isolated dc-dc stage that follows then converts the dc bus voltage to a regulated output dc voltage for charging batteries. The most common topologies used in the following dc-dc section are phase shifted ZVS topology [5]–[8], LLC resonant topology [9]–[11], and capacitive output filter soft switching converter [12]. Boost circuit-based PFC topologies operated in continuous conduction mode (CCM) and boundary conduction mode (BCM) are surveyed in this paper, targeting front end single-phase ac-dc power factor corrected converters in PHEV battery chargers. In the six sections that follow, five different boost based PFC topologies are discussed and experimental results are presented for each. The topologies in each section include: II. Conventional Boost Converter, III. Interleaved Boost Converter, IV. Phase Shifted Semi-Bridgeless Boost Converter, V. Bridgeless Interleaved Boost Converter, and VI. Bridgeless Interleaved Resonant Boost Converter. A topology comparison is presented in Section VII and the conclusions are presented in Section VIII. II. CONVENTIONAL BOOST CONVERTER The conventional boost topology is the most popular topology for PFC applications. It uses a dedicated diode bridge to rectify the ac input voltage to dc, which is then followed by the boost section, as shown in Fig. 2. In this topology, the output capacitor ripple current is very high [13] and is the difference between diode current and the dc output current. Furthermore, as the power level increases, the diode bridge losses significantly degrade the efficiency, so 1949-3053/$26.00 © 2011 IEEE 414 IEEE TRANSACTIONS ON SMART GRID, VOL. 3, NO. 1, MARCH 2012 Fig. 2. Conventional PFC boost converter. TABLE I CONVENTIONAL BOOST CONVERTER PROTOTYPE COMPONENTS Fig. 4. Efficiency versus output power at different input voltages for a conventional boost converter. Fig. 5. Interleaved PFC boost converter. B. Performance Evaluation of the Conventional Boost Converter Fig. 3. Input current, input voltage, and output voltage of a conventional boost V. Y-axis scales: Iin 10 A/div, Vin 100 V/div and Vo converter at 100 V/div. dealing with the heat dissipation in a limited area becomes problematic. The inductor volume also becomes a problematic design issue at high power. Another challenge is the power rating limitation for current sense resistors at high power. Due to these constraints, this topology is good for the low to medium power range, up to approximately 1 kW. For power levels kW, typically, designers parallel discrete semiconductors, or use expensive Diode semiconductor modules in order to deliver greater output power. An example of a module commonly used in industry is the APT50N60JCCU2 from Microsemi Corporation. A. Experimental Results of the Conventional Boost Converter An experimental prototype was built to verify the operation of the conventional boost PFC converter. The components used to build the prototype are listed in Table I. Fig. 3 shows the input voltage, input current and PFC bus voltage of the converter under the following test conditions: V, A, kW, V, kHz. Fig. 4 shows the efficiency of a conventional boost converter at input voltages ranging from 90 V to 265 V. As it can be noted from this graph, the efficiency drops significantly at low input line as the power increases. To solve this problem for power levels kW, discrete semiconductors are paralleled, or expensive modules are used. This reduces the power loss in the MOSFETs, but at low line, the input current increases and consequently the input bridge losses increase. As a result, the inductor current also increases. This requires a design compromise between the core, inductor size and inductance value. A lower inductance value for a boost inductor increases the input current ripple and consequently increases the input EMI filter size. It also increases the output capacitor high frequency ripple, thereby reducing the output capacitor lifetime. Therefore, it can be concluded that a conventional boost converter is not the preferred topology for PHEV battery charging applications. III. INTERLEAVED BOOST CONVERTER The interleaved boost converter, illustrated in Fig. 5, consists of two boost converters in parallel operating 180 out of phase [14]–[16]. The input current is the sum of the two input inductor currents. Because the inductors’ ripple currents are out of phase, they tend to cancel each other and reduce the input ripple current caused by the boost switching action. The interleaved boost converter has the advantage of paralleled semiconductors. Furthermore, by switching 180 out of phase, it doubles the effective switching frequency and introduces smaller input current ripple, so the input EMI filter is relatively small [17]–[19]. With ripple cancellation at the output, it also reduces stress on output MUSAVI et al.: EVALUATION AND EFFICIENCY COMPARISON OF FRONT END AC-DC PLUG-IN HYBRID CHARGER TOPOLOGIES 415 TABLE II INTERLEAVED BOOST CONVERTER PROTOTYPE COMPONENTS Fig. 7. Efficiency versus output power at different input voltages for an interleaved boost converter. Fig. 6. Input current, input voltage, and output voltage of an interleaved boost V. Y-axis scales: Iin 10 A/div, Vin 100 V/div, and Vo converter at 100 V/div. Fig. 8. Bridgeless PFC boost converter. capacitors. However, similar to the boost, this topology has the heat management problem for the input diode bridge rectifiers; therefore, it is limited to power levels up to approximately 3.5 kW. A. Experimental Results of the Interleaved Boost Converter An experimental prototype was built to verify the operation of the interleaved boost PFC converter. The components used to build the prototype are listed in Table II. Fig. 6 shows the input voltage, input current and PFC bus voltage of the converter under the following test conditions: V, A, kW, V, kHz. B. Performance Evaluation of the Interleaved Boost Converter Fig. 7 shows the efficiency of an interleaved boost converter at input voltages ranging from 90 V to 240 V. As it can be noted from these graphs, the output power level has increased. Hence, the efficiency profiles for each curve resemble those from the conventional boost converter. Despite the stated advantages of interleaving, the total power losses are the same compared to a conventional boost converter. IV. PHASE SHIFTED SEMI-BRIDGELESS BOOST CONVERTER The bridgeless boost PFC topology avoids the need for the rectifier input bridge yet maintains the classic boost topology [20]–[27], as shown in Fig. 8. It is an attractive solution for applications kW, where power density and efficiency are important. This converter solves the problem of heat management in the input rectifier Fig. 9. Phase shifted semi-bridgeless PFC boost converter [31]. diode bridge inherent to the conventional boost PFC, but it introduces increased EMI [28], [29]. Another disadvantage of this topology is the floating input line with respect to the PFC ground, making it impossible to sense the input voltage without a low frequency transformer or an optical coupler. Also, in order to sense the input current, complex circuitry is needed to sense the current in the MOSFET and diode paths separately, since the current path does not share the same ground during each half-line cycle [20], [30]. In order to address these issues, a phase shifted semi-bridgeless boost converter, shown in Fig. 9 was introduced in [31]. However, this topology does not achieve high full load efficiency since there is high power stress in the main MOSFETs due to high intrinsic body diode losses. A. Experimental Results of the Phase Shifted Semi-Bridgeless Boost Converter An experimental prototype was built to verify the operation of the phase shifted semi-bridgeless boost PFC converter. The components used to build the prototype are listed in Table III. Fig. 10 shows the input voltage, input current and PFC bus voltage of the converter under the following test conditions: 416 IEEE TRANSACTIONS ON SMART GRID, VOL. 3, NO. 1, MARCH 2012 Fig. 10. Input current, input voltage, and output voltage of a phase shifted semiV. Y-axis scales: Iin 10 A/div, Vin 100 bridgeless boost converter at V/div and Vo 100 V/div. Fig. 12. THD as a function of output power at V, and 70 kHz switching frequency. V and 240 V, TABLE III COMPONENT USED IN THE SEMI-BRIDGELESS BOOST CONVERTER PROTOTYPE Fig. 13. Power factor as a function of output power at V, and 70 kHz switching frequency. V, Fig. 11. Efficiency versus output power at different input voltages for a phase shifted semi-bridgeless boost converter. V, kHz. A, kW, V, B. Performance Evaluation of the Semi-Bridgeless Boost Converter Fig. 11 shows the efficiency of phase shifted semi-bridgeless boost converter at input voltages ranging from 90 V to 240 V. As it can be noted from this graph, the efficiency is significantly improved at light load. In order to verify the quality of the input current, the input current THD is shown in Fig. 12. The power factor and harmonic orders are given and compared with EN 61000-3-2 standard in Figs. 13 and 14. It is noted that mains current THD is less than 5% from 50% load to full load and it is compliant to EN 61000-3-2 (Figs. 12 and 14). The converter power factor is Fig. 14. Harmonics orders at EN61000-3-2 standard. V and 240 V and 240 V, compared against shown over entire load range for 120 and 240 V input in Fig. 13. The power factor is greater than 0.99 from 50% load to full load. These results show that the phase shifted semi-bridgeless PFC boost converter is ideally suited for automotive level I residential charging applications in North America where the typical supply is limited to 120 V and 1.44 kVA or 1.92 kVA. As an example, for 120 V input voltage and 1700 W load the efficiency is 95%, which is the same efficiency achieved with an interleaved boost converter operating with the same conditions. But at lighter loads, the semi-bridgeless converter achieves much higher efficiency. This is critical for converters used in applications such as battery chargers. In battery chargers, the converter is fully loaded for only one third of the total charging time (i.e., during the bulk charging stage). However, during the absorption and float stages, which are two thirds of the total 417 MUSAVI et al.: EVALUATION AND EFFICIENCY COMPARISON OF FRONT END AC-DC PLUG-IN HYBRID CHARGER TOPOLOGIES Fig. 15. Bridgeless interleaved PFC boost converter [34]. TABLE IV BRIDGELESS INTERLEAVED BOOST CONVERTER PROTOTYPE COMPONENTS Fig. 17. Efficiency versus output power at different input voltages for a bridgeless interleaved boost converter. Fig. 16. Input current, input voltage, and output voltage of a bridgeless interV. Y-axis scales: Iin 10 A/div, Vin 100 leaved boost converter at V/div, and Vo 100 V/div. charging time, the charger is only partially loaded, so light load efficiency is an important consideration. V. BRIDGELESS INTERLEAVED BOOST CONVERTER The bridgeless interleaved topology, shown in Fig. 15, was proposed as a solution to operate at power levels above 3.5 kW. In comparison to the interleaved boost PFC, it introduces two MOSFETs and also replaces four slow diodes with two fast diodes. The gating signals are 180 out of phase, similar to the interleaved boost. A detailed converter description and steady state operation analysis are given in [32]–[34]. This converter topology shows a high input power factor, high efficiency over the entire load range, and low input current harmonics. Since the proposed topology shows high input power factor, high efficiency over the entire load range, and low input current harmonics, it is a potential option for single phase PFC in high power level II battery charging applications. A. Experimental Results of the Bridgeless Interleaved Boost Converter An experimental prototype was built to verify the operation of the bridgeless interleaved boost PFC converter. The components used to build the prototype are listed in Table IV. Fig. 16 Fig. 18. THD as a function of output power at V, and 70 kHz switching frequency. V and 240 V, shows the input voltage, input current and PFC bus voltage of the converter under the following test conditions: V, A, kW, V, kHz. B. Performance Evaluation of the Bridgeless Interleaved Boost Converter Fig. 17 shows the efficiency of the bridgeless interleaved boost converter at input voltages ranging from 90 V to 240 V. In general, this converter achieves higher efficiency than both phase shifted semi-bridgeless converter and interleaved boost at the same power levels. In addition, due to the improved efficiency, greater output power can be achieved for a given input current. For example, at 240 V input, the maximum output power increases from 3.4 kW for the phase shifted semi-bridgeless converter up to 4.2 kW for the bridgeless interleaved boost converter. Curves of the input current total harmonic distortion are provided in Fig. 18 for full load at 120 V and 240 V input. It is noted that the input current THD is less than 5% from half load to full load. Power factor is another useful parameter to show the quality of input current. The converter power factor is provided in Fig. 19 for the entire load range at 120 V and 240 V input. The power factor is greater than 0.99 from half load to full load. 418 IEEE TRANSACTIONS ON SMART GRID, VOL. 3, NO. 1, MARCH 2012 Fig. 21. Bridgeless interleaved resonant PFC boost converter [35]. Fig. 19. Power factor as a function of output power at V, and 70 kHz switching frequency. V, V and 240 Fig. 22. Efficiency versus output power at 230 V input voltages for a bridgeless interleaved resonant boost converter by Infineon Technologies AG [35]. TABLE V BRIDGELESS INTERLEAVED RESONANT BOOST CONVERTER PROTOTYPE COMPONENTS Fig. 20. Harmonics orders at EN61000-3-2 standard. V and 240 V, compared against In order to verify the quality of the input current in the proposed topology, its harmonics up to the 39th harmonic are given and compared with the EN 61000-3-2 standard in Fig. 20 for 120 V and 240 V input. All converter harmonics are well below IEC standard, which is required for PHEV chargers. These results demonstrate that the bridgeless interleaved boost converter is ideally suited for automotive level II residential charging applications in North America and Europe where the typical supply is limited to input voltages of 240/250 V, and power levels up to approximately 8 kVA—depending on the input supply breaker limitation. VI. BRIDGELESS INTERLEAVED RESONANT BOOST CONVERTER The bridgeless interleaved resonant topology operating in BCM was first introduced by Infineon Technologies [35] and proposed for front end ac-dc stage of level II on-board chargers. The topology is illustrated in Fig. 21. Compared to the bridgeless interleaved boost converter, it replaces the four fast diodes with four slow diodes; however, it requires two high side drivers for MOSFETs -Q1 and Q2 as well as two low side drivers for Q3 and Q4. The other drawbacks with this topology include the need for at least two sets of current sensors, two snubbers, and a complex digital control scheme. A. Experimental Results and Performance Evaluation of the Bridgeless Interleaved Resonant Boost Converter The operation of this converter and efficiency was reported in [35]. The components used for the prototype are listed in Table V. Fig. 22 shows the reported efficiency (reproduced) of the converter under the following test conditions: V, A, , V. This converter achieves a peak efficiency of 97.9% at 2.7 kW load, but the efficiency degrades rapidly beyond the output power of 2.7 kW, so based on the reported data, it is not an ideal candidate for automotive level II charging. VII. TOPOLOGY COMPARISON Prototypes of the converter presented in Sections II–V were built to provide data for a qualitative and quantitative performance comparison. The ac power source and dc electronics load used in the test set-up are California Instrument Model 5001 iX and Chroma Model 63204 respectively. Loss analysis modeling was also performed to gain insight into the noted qualitative advantages/disadvantages of each prototype in comparison to the measured efficiency. MUSAVI et al.: EVALUATION AND EFFICIENCY COMPARISON OF FRONT END AC-DC PLUG-IN HYBRID CHARGER TOPOLOGIES 419 Fig. 24. Efficiency versus output power for different PFC boost converters. Fig. 23. Loss distribution in semiconductors at kW, and kHz. V, V, Fig. 23 shows the modeled loss distribution within the semiconductors for these topologies at V, W, V, and kHz. The regular diode losses consist of only conduction losses in bridge rectifier diodes, i.e., reverse recovery losses were neglected due to the low frequency mains input. Due to the low reverse recovery characteristics ofSiC, these diodes were selected for the boost diodes. Therefore reverse recovery losses were neglected for these diodes, so that only conduction losses were considered. Switching loss, conduction loss, gate charge loss and CV loss are included in the MOSFET losses. The inductor losses were neglected in the comparison. The regular diodes in input bridge rectifiers have the largest share of losses among the topologies with the input bridge rectifier. The bridgeless topologies eliminate this large loss component W . However, the tradeoff is that the MOSFET losses are higher and the intrinsic body diodes of MOSFETs conduct, producing new losses W . The fast diodes in the bridgeless interleaved PFC have slightly lower power losses, since the boost diode average current is lower in these topologies. Overall the MOSFETs have increased current stress in the bridgeless topologies, but the total semiconductor losses for the bridgeless interleaved boost are 37% lower than the benchmark conventional boost and 37% lower than the interleaved boost. Since the bridge rectifier losses are so large, it was expected that bridgeless interleaved boost converter would have the lowest power losses among the topologies studied in Sections II–V. Also, it was noted that the losses in the input bridge rectifiers were 56% of total losses in the conventional PFC converter and in the interleaved PFC converter. Therefore eliminating the input bridges in PFC converters is justified despite the fact that new losses are introduced. A more detailed circuit analysis and loss evaluation for the proposed level I and level II chargers are given in [31], [34] Fig. 24 illustrates the measured efficiency as a function of output power for all five topologies studied under the following operating conditions: kHz, V, and V. All semiconductor and magnetic devices used in prototype units were the same. Limited information was available for Infineon bridgeless interleaved resonant converter. Notably it was measured at 230 V input voltage. TABLE VI TOPOLOGY OVERVIEW/COMPARISON Table VI demonstrates an overall overview and comparison of all candidate topologies discussed for the front end ac-dc stage of a PHEV battery charger. The phase shifted semi-bridgeless PFC converter was the topology of choice for level I chargers and the bridgeless interleaved PFC converter is an optimal topology for level II chargers. VIII. CONCLUSIONS A topology survey aimed at evaluating topologies for use in front end ac-dc converters for PHEV battery chargers is presented in this paper. The potential converter solutions have been analyzed and their performance characteristics are presented. Several prototype converter circuits were built to verify the proof-of-concept. The results show that the phase shifted semi bridgeless converter is ideally suited for automotive level I residential charging applications in North America where the typical supply is limited to 120 V and 1.44 kVA or 1.92 kVA. For high power level II residential charging applications, the bridgeless interleaved boost converter is an ideal topology candidate in North America and Europe where the typical supply is limited to input voltages of 240/250 V and power levels up to 8 kVA. 420 IEEE TRANSACTIONS ON SMART GRID, VOL. 3, NO. 1, MARCH 2012 REFERENCES [1] Y. J. Lee, A. Khaligh, and A. Emadi, “Advanced integrated bidirectional AC-DC and DC-DC converter for plug-in hybrid electric vehicles,” IEEE Trans. Veh. Technol., vol. 58, pp. 3970–3980, Oct. 2009. [2] K. Morrow, D. Karner, and J. Francfort, Plug-in Hybrid Electric Vehicle Charging Infrastructure Review. : U.S. Department of Energy—Vehicle Technologies Program, 2008. [3] L. Petersen and M. Andersen, “Two-stage power factor corrected power supplies: The low component-stress approach,” in Proc. 2002 IEEE Appl. Power Electron. Conf. Expo., vol. 2, pp. 1195–1201. [4] B. Singh, B. N. Singh, A. Chandra, K. Al-Haddad, A. Pandey, and D. P. Kothari, “A review of single-phase improved power quality AC-DC converters,” IEEE Trans. Ind. Electron., vol. 50, pp. 962–981, 2003. [5] J. A. Sabate, V. Vlatkovic, R. B. Ridley, F. C. Lee, and B. H. Cho, “Design considerations for high-voltage high-power full-bridge zerovoltage-switched PWM converter,” in Proc. 1990 IEEE Appl. Power Electron. Conf. Expo., pp. 275–284. [6] R. Redl, L. Balogh, and D. W. Edwards, “Optimum ZVS full-bridge DC/DC converter with PWM phase-shift control: Analysis, design considerations, and experimental results,” in Proc. 1994 Appl. Power Electron. Conf. Expo., vol. 1, pp. 159–165. [7] Y. Jang, M. M. Jovanovic, and Y.-M. Chang, “A new ZVS-PWM full-bridge converter,” IEEE Trans. Power Electron., vol. 18, pp. 1122–1129, Sep. 2003. [8] D. Gautam, F. Musavi, M. Edington, W. Eberle, and W. G. Dunford, “An automotive on-board 3.3 kW battery charger for PHEV application,” in Proc. 7th IEEE Veh. Power Propulsion Conf., Chicago, IL, 2011. [9] R. Beiranvand, B. Rashidian, M. R. Zolghadri, and S. M. H. Alavi, “Using LLC resonant converter for designing wide-range voltage source,” IEEE Trans. Ind. Electron., vol. 58, pp. 1746–1756, May 2011. [10] W.-Y. Choi, B.-H. Kwon, and J.-S. Lai, “A hybrid switching scheme for LLC series-resonant half-bridge DC-DC converter in a wide load range,” in Proc. 2010 IEEE Appl. Power Electron. Conf. Expo., pp. 1494–1497. [11] J. S. Kim, G. Y. Choe, H. M. Jung, B. K. Lee, Y. J. Cho, and K. B. Han, “Design and implementation of a high-efficiency on- board battery charger for electric vehicles with frequency control strategy,” in Proc. 2010 IEEE Veh. Power Propulsion Conf., pp. 1–6. [12] I. D. Jitaru, “A 3 kW soft switching DC-DC converter,” in Proc. 2000 IEEE Appl. Power Electron. Conf. Expo., vol. 1, pp. 86–92. [13] D. Xu, J. Zhang, W. Chen, J. Lin, and F. C. Lee, “Evaluation of output filter capacitor current ripples in single phase PFC converters,” in Proc. 2002 Power Convers. Conf. (PCC), Osaka, Japan, vol. 3, pp. 1226–1231. [14] M. O’Loughlin, “An interleaved PFC preregulator for high-power converters,” Proc. Texas Instrum. Power Supply Design Seminar, vol. Topic 5, pp. 5-1–5-14, 2007. [15] L. Balogh and R. Redl, “Power-factor correction with interleaved boost converters in continuous-inductor-current mode,” in Proc. 1993 IEEE Appl. Power Electron. Conf. Expo., pp. 168–174. [16] Y. Jang and M. M. Jovanovic, “Interleaved boost converter with intrinsic voltage-doubler characteristic for universal-line PFC front end,” IEEE Trans. Power Electron., vol. 22, pp. 1394–1401, Jul. 2007. [17] C. Wang, M. Xu, and F. C. Lee, “Asymmetrical interleaving strategy for multi-channel PFC,” in Proc. 2008 IEEE Appl. Power Electron. Conf. Expo., pp. 1409–1415. [18] P. Kong, S. Wang, F. C. Lee, and C. Wang, “Common-mode EMI study and reduction technique for the interleaved multichannel PFC converter,” IEEE Trans. Power Electron., vol. 23, pp. 2576–2584, Sep. 2008. [19] C. Wang, M. Xu, F. C. Lee, and B. Lu, “EMI study for the interleaved multi-channel PFC,” in Proc. 2007 IEEE Power Electron. Specialists Conf., pp. 1336–1342. [20] U. Moriconi, “A bridgeless PFC configuration based on L4981 PFC controller,” STMicroelectronics Application Note AN1606,, 2002. [21] B. Lu, R. Brown, and M. Soldano, “Bridgeless PFC implementation using one cycle control technique,” in Proc. 2005 IEEE Appl. Power Electron. Conf. Expo., vol. 2, pp. 812–817. [22] C. Petrea and M. Lucanu, “Bridgeless power factor correction converter working at high load variations,” in Proc. 2007 Int. Symp. Signals, Circuits, Syst. (ISSCS), vol. 2, pp. 1–4. [23] J. M. Hancock, “Bridgeless PFC boosts low-line efficiency,” Power Electron. Technol., 2008 [Online]. Available: http://powerelectronics. com/power_management/power_ics/bridgeless-pfc-low-line-efficiency-0225/ [24] L. Huber, J. Yungtaek, and M. M. Jovanovic, “Performance evaluation of bridgeless PFC boost rectifiers,” IEEE Trans. Power Electron., vol. 23, pp. 1381–1390, May 2008. [25] Y. Jang, M. M. Jovanovic, and D. L. Dillman, “Bridgeless PFC boost rectifier with optimized magnetic utilization,” in Proc. 2008 IEEE Appl. Power Electron. Conf. Expo., pp. 1017–1021. [26] Y. Jang and M. M. Jovanovic, “A bridgeless PFC boost rectifier with optimized magnetic utilization,” IEEE Trans. Power Electron., vol. 24, pp. 85–93, Jan. 2009. [27] W. Y. Choi, J. M. Kwon, E. H. Kim, J. J. Lee, and B. H. Kwon, “Bridgeless boost rectifier with low conduction losses and reduced diode reverse-recovery problems,” IEEE Trans. Ind. Electron., vol. 54, pp. 769–780, Apr. 2007. [28] T. Baur, M. Reddig, and M. Schlenk, “Line-conducted EMI-behaviour of a high efficient PFC-stage without input rectification,” in Infineon Technology—Application Note, 2006. [29] W. Frank, M. Reddig, and M. Schlenk, “New control methods for rectifier-less PFC-stages,” in Proc. 2005 IEEE Int. Symp. Ind. Electron., vol. 2, pp. 489–493. [30] P. Kong, S. Wang, and F. C. Lee, “Common mode EMI noise suppression for bridgeless PFC converters,” IEEE Trans. Power Electron., vol. 23, pp. 291–297, Jan. 2008. [31] F. Musavi, W. Eberle, and W. G. Dunford, “A phase shifted semibridgeless boost power factor corrected converter for plug in hybrid electric vehicle battery chargers,” in Proc. 2011 IEEE Appl. Power Electron. Conf. Expo., pp. 821–828. [32] F. Musavi, W. Eberle, and W. G. Dunford, “A high-performance single-phase AC-DC power factor corrected boost converter for plug in hybrid electric vehicle battery chargers,” Proc. 2010 IEEE Energy Convers. Congr. Expo., pp. 3588–3595. [33] F. Musavi, W. Eberle, and W. G. Dunford, “Efficiency evaluation of single-phase solutions for AC-DC PFC boost converters for plug-inHybrid electric vehicle battery chargers,” in Proc. 2010 IEEE Veh. Power Propulsion Conf., pp. 1–6. [34] F. Musavi, W. Eberle, and W. G. Dunford, “A high-performance single-phase bridgeless interleaved PFC converter for plug-in hybrid electric vehicle battery chargers,” IEEE Trans. Ind. Appl., vol. 47, no. 4, pp. 1833–1843, Jul./Aug. 2011. [35] “On board charging: Concept consideration and demonstrator hardware,” in Proc. 25th World Electric Veh. Symp. Expo. (EVS) Infineon Technol., Shenzhen, China, 2010. Fariborz Musavi (S’10–M’11) received the B.Sc. degree from Iran University of Science and Technology, Tehran, Iran, in 1994, the M.Sc. degree from Concordia University, Montreal, QC, Canada, in 2001, and the Ph.D. degree in electrical engineering with emphasis in power electronics from the University of British Columbia, Vancouver, BC, Canada. Since 2001, he has been with several high-tech companies including EMS Technologies Inc., Montreal, QC, Canada, DRS Pivotal Power, Bedford, NS, Canada and Alpha Technologies, Bellingham, WA, USA. Currently he is with Delta-Q Technologies Corp., Burnaby, BC, Canada, where he works as the Manager of Research, Engineering and is engaged in research on simulation, analysis, and design of battery chargers for industrial and automotive applications. His current research interests include high power, high efficiency converter topologies, high power factor rectifiers, grid-tied inverters, electric vehicles, and sustainable and renewable energy sources. Dr. Musavi is a Registered Professional Engineer in the Province of British Columbia. He was the recipient of the First Prize Paper Award from the IEEE Industry Applications Society Industrial Power Converter Committee in 2011. Murray Edington (M’02) studied engineering at Cambridge University and the University of Newcastle upon Tyne. He has 14 years experience in developing automotive power electronics products (specifically EV and hybrid system components) and 11 years previous experience in the development of industrial power electronics products. Industrial experience includes positions at Ricardo Consulting Engineers, Motorola Automotive Industrial Electronics Group, Farnell Advance Power, and Wavedriver Ltd. He is currently Director of Product Engineering at Delta-Q Technologies Corp., Vancouver, BC, Canada. MUSAVI et al.: EVALUATION AND EFFICIENCY COMPARISON OF FRONT END AC-DC PLUG-IN HYBRID CHARGER TOPOLOGIES Wilson Eberle (S’98–M’07) received the B.Sc., M.Sc., and Ph.D. degrees from the Department of Electrical and Computer Engineering, Queen’s University, Kingston, ON, Canada, in 2000, 2003, and 2008, respectively. From 1997 to 1999, he was an Engineering Co-Op Student at Ford Motor Company, Windsor, ON, and at Astec Advanced Power Systems, Nepean, ON. He is currently an Assistant Professor in the School of Engineering, University of British Columbia, Kelowna, BC, Canada. He is the author or coauthor of more than 20 technical papers published in various conferences and IEEE journals. He is the holder of one U.S. pending patent. He is also the holder of international pending patents. His current research interests include high-efficiency, high-power density, low-power dc-dc converters, digital control techniques for dc-dc converters, electromagnetic interference (EMI) filter design for switching converters, and resonant gate drive techniques for dc-dc converters. Dr. Eberle was the recipient of the Ontario Graduate Scholarship and has won awards from the Power Source Manufacturer’s Association (PSMA) and the Ontario Centres of Excellence (OCE) to present papers at conferences. 421 William G. Dunford (S’78–M’81–SM’92) was a student at Imperial College, London, UK, and the University of Toronto, Toronto, ON, Canada. Industrial experience includes positions at the Royal Aircraft Establishment (now Qinetiq), Schlumberger, and Alcatel. He has had a long term interest in photovoltaic powered systems and is also involved in projects in the automotive and energy harvesting areas. He is a director of Legend Power Systems, Burnaby, BC, Canada, where he has also been active in product development. He has also been a faculty member at Imperial College and the University of Toronto, and is now on the faculty of the University of British Columbia, Vancouver, Canada. Dr. Dunford has served in various positions on the Advisory Committee of the IEEE Power Electronics Society and chaired PESC in 1986 and 2001.