Using a Hexagonal Mirror for Varying Light Intensity in the

advertisement

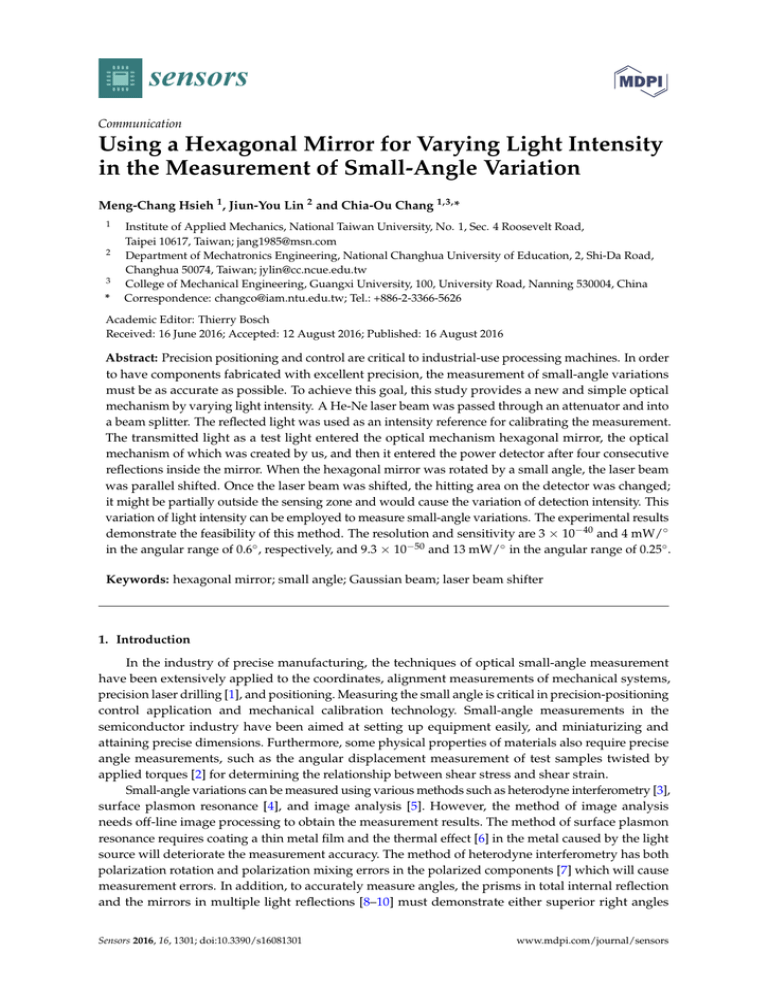

sensors Communication Using a Hexagonal Mirror for Varying Light Intensity in the Measurement of Small-Angle Variation Meng-Chang Hsieh 1 , Jiun-You Lin 2 and Chia-Ou Chang 1,3, * 1 2 3 * Institute of Applied Mechanics, National Taiwan University, No. 1, Sec. 4 Roosevelt Road, Taipei 10617, Taiwan; jang1985@msn.com Department of Mechatronics Engineering, National Changhua University of Education, 2, Shi-Da Road, Changhua 50074, Taiwan; jylin@cc.ncue.edu.tw College of Mechanical Engineering, Guangxi University, 100, University Road, Nanning 530004, China Correspondence: changco@iam.ntu.edu.tw; Tel.: +886-2-3366-5626 Academic Editor: Thierry Bosch Received: 16 June 2016; Accepted: 12 August 2016; Published: 16 August 2016 Abstract: Precision positioning and control are critical to industrial-use processing machines. In order to have components fabricated with excellent precision, the measurement of small-angle variations must be as accurate as possible. To achieve this goal, this study provides a new and simple optical mechanism by varying light intensity. A He-Ne laser beam was passed through an attenuator and into a beam splitter. The reflected light was used as an intensity reference for calibrating the measurement. The transmitted light as a test light entered the optical mechanism hexagonal mirror, the optical mechanism of which was created by us, and then it entered the power detector after four consecutive reflections inside the mirror. When the hexagonal mirror was rotated by a small angle, the laser beam was parallel shifted. Once the laser beam was shifted, the hitting area on the detector was changed; it might be partially outside the sensing zone and would cause the variation of detection intensity. This variation of light intensity can be employed to measure small-angle variations. The experimental results demonstrate the feasibility of this method. The resolution and sensitivity are 3 × 10−40 and 4 mW/◦ in the angular range of 0.6◦ , respectively, and 9.3 × 10−50 and 13 mW/◦ in the angular range of 0.25◦ . Keywords: hexagonal mirror; small angle; Gaussian beam; laser beam shifter 1. Introduction In the industry of precise manufacturing, the techniques of optical small-angle measurement have been extensively applied to the coordinates, alignment measurements of mechanical systems, precision laser drilling [1], and positioning. Measuring the small angle is critical in precision-positioning control application and mechanical calibration technology. Small-angle measurements in the semiconductor industry have been aimed at setting up equipment easily, and miniaturizing and attaining precise dimensions. Furthermore, some physical properties of materials also require precise angle measurements, such as the angular displacement measurement of test samples twisted by applied torques [2] for determining the relationship between shear stress and shear strain. Small-angle variations can be measured using various methods such as heterodyne interferometry [3], surface plasmon resonance [4], and image analysis [5]. However, the method of image analysis needs off-line image processing to obtain the measurement results. The method of surface plasmon resonance requires coating a thin metal film and the thermal effect [6] in the metal caused by the light source will deteriorate the measurement accuracy. The method of heterodyne interferometry has both polarization rotation and polarization mixing errors in the polarized components [7] which will cause measurement errors. In addition, to accurately measure angles, the prisms in total internal reflection and the mirrors in multiple light reflections [8–10] must demonstrate either superior right angles Sensors 2016, 16, 1301; doi:10.3390/s16081301 www.mdpi.com/journal/sensors Sensors2016, 16, 1301 2 of 9 Sensors 2016, 16, 1301 2 of 9 prisms in total internal reflection and the mirrors in multiple light reflections [8–10] must demonstrate either superior right angles or parallelism; if the parallelism or right angle of a prism is notparallelism; perfect, it will measurement [7].a prism There is are and measurement displacement or if thecause parallelism or right errors angle of notexcellent perfect, angular it will cause measurement methods [11–13]angular but these are methods complicated. To but facilitate errors [7]. There are excellent and measurement displacement structures measurement [11–13] these fabricating components with high precision and to avoid the aforementioned measurement errors, measurement structures are complicated. To facilitate fabricating components with high precision this to study proposes a new and simple opticalerrors, mechanism, which is a hexagonal can and avoid the aforementioned measurement this study proposes a new andmirror simplethat optical parallel shift which the light and cause variations of light intensity at the detector. To cause reducevariations the effect mechanism, is path a hexagonal mirror that can parallel shift the light path and of light unstable sourceatintensity on measurements, the intensity of thesource test light is divided by that of the of intensity the detector. To reduce the effect of unstable intensity on measurements, reference light. system will present highly measurements This the intensity of theTherefore, test light isthis divided by that of the reference light.stable Therefore, this system [7,14]. will present measurement of the light intensity variation can be utilized to evaluate small-angle variation. The highly stable measurements [7,14]. This measurement of the light intensity variation can be utilized to proposed approach provides various advantages, such as a simple structure, high sensitivity, and evaluate small-angle variation. The proposed approach provides various advantages, such as a simple high stability. structure, high sensitivity, and high stability. 2. Materials Materialsand andMethods Methods 2.1. 2.1. Laser Laser Beam Beam Parallel Parallel Shifter Shifter A model waswas usedused in thisinstudy. mirrors installed four consecutive A regular regularhexagon hexagon model this Four study. Four were mirrors wereoninstalled on four hexagonal sidewalls served as a laser beam parallel shifter as shown in Figure 1a. When a laser beam consecutive hexagonal sidewalls served as a laser beam parallel shifter as shown in Figure 1a. When hit the first mirror and reflected four 1a, the(Figure solid line), the solid reflected a laser beam hit the first mirror off andthrough reflected off mirrors through(Figure four mirrors 1a, the line),light the off the un-rotated hexagonal mirror was defined as the first light. When the hexagonal mirror rotated reflected light off the un-rotated hexagonal mirror was defined as the first light. When the hexagonal an angle ∆θ, the off the hexagonal mirror (Figure 1a, the dash1a, line) the mirror rotated an reflected angle Δθ,light the reflected light off the hexagonal mirror (Figure thewas dashcalled line) was second light. After the After second the first the lightfirst path of path AB isofparallel to the second തതതത is parallel called the second light. themirror secondreflection, mirror reflection, light ܤܣ to the path of CD as shown in Figure 1a; these two light paths are also parallel after the fourth mirror തതതത second path of ܦܥas shown in Figure 1a; these two light paths are also parallel after the fourth reflection (the geometric drawing based on the on lawthe of law reflection, that is,that the is, incident angle is equal mirror reflection (the geometric drawing based of reflection, the incident angle is to the to reflective angle,angle, it directly reveal that the lightlight paths are are parallel through even times of equal the reflective it directly reveal thattwo the two paths parallel through even times reflections). TheThe shifted distance between the first second is denoted ∆Z. Forby hexagonal of reflections). shifted distance between theand first and light second light is by denoted ΔZ. For mirror, ∆Z is increased, the reflection times do. In addition, the angle variation ∆θ is, hexagonal mirror, ΔZ isasincreased, as the reflection times do.the Inlarger addition, the larger the angle the greaterΔθ theis,shifted distance ∆Z becomes, as shown in Figure 1a. variation the greater the shifted distance ΔZ becomes, as shown in Figure 1a. the angular variation. (a) (a) Hexagonal mirror; (b) Figure 1. Parallel Parallelshift shiftlight lightpaths pathsbefore beforeand andafter after the angular variation. Hexagonal mirror; Square mirror. (b) Square mirror. The toto create anan angle sensor for for measuring the The characteristics characteristicsof ofhexagonal hexagonalmirror mirrorwere wereutilized utilized create angle sensor measuring rotation angle according to to thethe distance between hexagonal the rotation angle according distance betweenthe theparallel paralleltwo tworeflective reflective lights. lights. For For hexagonal mirror, the expression relating ΔZ and Δθ is given by Equation (1), mirror, the expression relating ∆Z and ∆θ is given by Equation (1), Z √ 2 3 R sin( ) , ∆Z = 2 3Rsin(∆θ ), (1) (1) which is derived in detail in the appendix. The R in Equation (1) is the circumradius and equal to the which is derived in detail in the Supplementary Materials. The R in Equation (1) is the circumradius side length of regular hexagon. Figure 1b shows the parallel shifted light path of square mirror before and equal to the side length of regular hexagon. Figure 1b shows the parallel shifted light path of and after the angle variation. The relationship between ΔZ and Δθ is derived as (see Appendix) square mirror before and after the angle variation. The relationship between ∆Z and ∆θ is derived as Zs 2 R sin( ) (see Supplementary Materials) (2) ∆Zs = 2Rsin(∆θ ) (2) Sensors 2016, 16, Sensors2016, 16, 1301 1301 3 3ofof9 9 Sensors2016, 16, 1301 3 of 9 By the comparison between Equations (1) and (2), it is found that, for the same radius of By between Equations (1) and it is is found found that, for the the same same radius of Bythe thecomparison comparison between Equations (1)hexagonal and (2), (2), mirror it that, for radius of circumcircle R and same angle variation Δθ, the has the greater shifted distance ΔZ circumcircle R and same angle variation ∆θ, the hexagonal mirror has the greater shifted distance ∆Z circumcircle R and samemirror. angle variation Δθ, the hexagonal mirrorprovides has the greater ΔZ than ΔZs of the square Therefore, the hexagonal mirror higher shifted angulardistance sensitivity than ∆Zs of the square mirror. Therefore, the hexagonal mirror provides higher angular sensitivity than than ΔZs of the square mirror. Therefore, the hexagonal mirror provides higher angular sensitivity than the square mirror. At the same circumcircle size, the more the regular polygon number is, the the square mirror.mirror. At is, theand same size, the more the regular polygon number is, theis, better than the At the same circumcircle size, theis. more the regular polygon number the better thesquare sensitivity thecircumcircle less the measurable range the sensitivity is, and the less the measurable range is. better the sensitivity is, between and the less thetwo measurable When the distance these lights hadrange been is. measured, the variations of rotation angle When the these two had been measured, the variations ofrotation rotation angle When thedistance distance between these two lights lights variations of angle would be determined bybetween Equation (1), where the side-length of regularthe hexagon is equal to the radius would be determined by Equation (1), where the side-length of regular hexagon is equal to the radius would be determined byhere. Equation (1), where the simulation side-lengthresult using Equation is (1) equal to the radius R and was given 40 mm Figure 2 shows to demonstrate Rthe was 40 Figure 22 shows (Δθ) the simulation using Equation Equation (1)results todemonstrate demonstrate Rand and wasgiven givenbetween 40mm mmhere. here. Figure resultdistance using (1) to relationship the angle variation and the shifted (ΔZ). The indicate the relationship between the angle variation (∆θ) and the shifted distance (∆Z). The results indicate the relationship between the angle variation (Δθ) and the distance (ΔZ). The results indicate that the angle and distance variation are relatively linear within ±3°. To prevent the last reflective ◦ . To prevent the last reflective that the angle and distance variation are relatively linear within ± 3 that the angle and distance variationmirror, are relatively linear angle withinwas ±3°.restricted To prevent the ±2°. last reflective point being outside of the hexagonal the rotational within point 2◦ . pointbeing beingoutside outsideofofthe thehexagonal hexagonalmirror, mirror,the therotational rotationalangle angle was was restricted restricted within within ± ±2°. Figure 2. Relationship between Δθ and ΔZ. Figure 2. 2. Relationship Relationship between and ΔZ. Figure between Δθ ∆θ and ∆Z. 2.2. Laser Parallel Shift and Light Intensity Variation 2.2.Laser LaserParallel ParallelShift Shiftand andLight LightIntensity Intensity Variation 2.2. The hexagonal mirror is an optical Variation mechanism for detecting the angle variation by measuring The hexagonal mirror is an optical mechanism for detecting detecting angle measuring the shifted distance.mirror As theislight beam was parallel shifted due to the motion by of mirror, The hexagonal an optical mechanism for the angular angle variation variation bythe measuring the shifted distance. As the light beam was parallel shifted due to the angular motion of the the hitting point would advance from the outer-casing of power detector (NOVA II, Sensor size: 12.5 the shifted distance. As the light beam was parallel shifted due to the angular motion of themirror, mirror, the hitting point would advance from the outer-casing of power detector (NOVA II, Sensor size: × 12.5 mm, OPHIR, Jerusalem, Israel) to its sensing zone, as shown in Figure 3; that is, the hitting point the hitting point would advance from the outer-casing of power detector (NOVA II, Sensor 12.5 size: × 12.5 mm,mm, OPHIR, Jerusalem, Israel) to zone, aspoint shown in Figure 3;2 that the hitting point 1 sensing at the outer-casing boundary marked byits ○ to the by ○ located atis, thethe sensing 12.5 × 12.5 OPHIR, Jerusalem, Israel) tomoved its sensing zone, asmarked shown in Figure 3;is,that hitting 1 laser 2 the at theatAfter outer-casing marked by of ○ moved to the point marked by ○ located at the sensing 2 , the boundary zone. ○ Gaussian waveform was completely zone, 1beam 2 located point the outer-casing boundary marked by moved to the point inside marked bysensing atthe the 2 saturated. zone. After ○ , the 2Gaussian waveforminofintensity laser beam was completely insideinthe sensing zone, the intensity was The variation is particularly prominent the vicinity of sensing zone. After , the Gaussian waveform of laser beam was completely inside the sensinglight zone, intensity was saturated. The variation in intensity is particularly prominent in the vicinity of light beam crossing boundary. that was used as the sensing range for the the intensity wasthe saturated. TheThus, variation insensitive intensityrange is particularly prominent in the vicinity of light beam crossing the boundary. Thus, that sensitive range was used as the sensing range for the detection. beam crossing the boundary. Thus, that sensitive range was used as the sensing range for the detection. detection. Figure shifts corresponding corresponding to to light light intensity intensityvariations. variations. Figure 3. 3. Light Light parallel parallel shifts Figure 3. Light parallel shifts corresponding to light intensity variations. Sensors2016, 16, 1301 4 of 9 Sensors 2016, 16, 1301 4 of 9 2.3. The Definition of Laser Gaussian Distribution σ Value TheThe intensity distribution of theDistribution laser can σ beValue considered a Gaussian distribution [15–17] having 2.3. Definition of Laser Gaussian its general form expressed as Equation (3): The intensity distribution of the laser can be considered a Gaussian distribution [15–17] having its 2 x2 general form expressed as Equation (3): z r z= 2 2 e 2 2 − 2x22 σ2 π e (3) (3) σ In order to determine the value σ of laser Gaussian distribution, the laser light source was Indisplaced order to determine thetovalue σ of Gaussian distribution, the laser laser light light source source intensity was gradually from 0 mm 4.2 mm aslaser shown in Figure 3. When the gradually displaced from 0 mm to 4.2 mm as shown in Figure 3. When the laser light source intensity is located at position ci (the central position of laser spot) its intensity is expressed by Equation (4) as is located at position ci (the central position of laser spot) its intensity is expressed by Equation (4) as 2( x ci ) 2 d 12.5 6.25 2d+12.5 I (ci , ) I 0 2 Z 2 I (ci , σ ) = I0 2 σ π d e 6.25 Z d 6.25 e 2 2( x − c i )2 σ2 2 y2 e e 2 dydx 2y2 dydx σ2 , , (4) (4) −6.25 where Io represents the laser intensity and d is the distance from the origin of the coordinate to the where Io represents the laser intensity and dinisFigure the distance the and origin of the coordinate left boundary of the sensing zone as shown 3. Thefrom upper lower limits of theto y the integral left boundary of the sensing zone as shown in Figure 3. The upper and lower limits of the y integral (±6.25 mm) are determined by the size of power detector. Equation (4) shows that the change of laser 6.25 mm) by the size detector. Equation (4) shows that the change of laser spot(± position ci are willdetermined alter the intensity I(cofi, power σ). spot position ci will alter the intensity I(ci , σ). To evaluate the undetermined value σ, the numerical approximation conducts the principle of To evaluate the undetermined value σ, the numerical approximation conducts the principle of minimizing the square root of sum of squared difference between the experimental measurement minimizing the square root of sum of squared difference between the experimental measurement intensity (mi)(m and theoretical one i, σ), which is expressed by Equation (5) as intensity ) and theoretical oneI(c I(c , σ), which is expressed by Equation (5) as i i v 8 u 8 Error ( ) u ( I (ci , ) mi ) 2 Error (σ ) = t ∑i 1( I (ci , σ ) − mi )2 (5) (5) i =1 The error function Equation (5) was calculated and plotted versus σ in Figure 4. The error function Equation (5) was calculated and plotted versus σ in Figure 4. Figure 4. The distribution of error between the experimental and theoretical values in different σ. Figure 4. The distribution of error between the experimental and theoretical values in different σ. σ was found to be 0.976 according to the minimum of error function shown in Figure 4. TheThe σ was found to be 0.976 according to the minimum of error function shown in Figure 4. The The theoretical intensity based on σ = 0.976 matches very well with the measured one as shown in theoretical intensity based on σ = 0.976 matches very well with the measured one as shown in Figure 3. Figure 3. 3. Experimental Setup 3. Experimental Setup In the proposed experimental scheme, scheme, the laser Melles Griot, In the proposed experimental laser light lightsource source(25LHP925-249, (25LHP925-249, Melles Griot, Carlsbad, USA) fitted with an attenuator as shown in Figure 5. When rotary stage Carlsbad, CA,CA, USA) waswas fitted with an attenuator as shown in Figure 5. When thethe rotary stage (SGSP60YAW, Opto Sigma, Santa Ana, CA, USA) was rotated in a small angle and the laser beam was shifted, the hitting area on the detector was changed and might be partially outside the sensing zone, it would cause the variation of detection intensity, as shown in Figures 3 and 5. To avoid measurement errors caused by the inclined hexagonal mirror and the unstable laser intensity, the Sensors 2016, 16, 1301 5 of 9 (SGSP-60YAW, Opto Sigma, Santa Ana, CA, USA) was rotated in a small angle and the laser beam was shifted, the hitting area on the detector was changed and might be partially outside the sensing zone, it would cause the Sensors2016, 1301variation of detection intensity, as shown in Figures 3 and 5. To avoid measurement 5 of Sensors2016, 16,16, 1301 5 of 9 9 errors caused by the inclined hexagonal mirror and the unstable laser intensity, the position calibration position calibration the mirror was performed and a beam splitter (BS) was used split athe reference of the mirror was performed and was a beam splitter (BS) was used to split a reference light from laser, position calibration ofof the mirror performed and a beam splitter (BS) was used toto split a reference light from the laser, respectively. The reference light intensity (Ir) detected by the reference power respectively. The reference light intensity (Ir) is detected by the reference powerby detector (PDr) and the light from the laser, respectively. The reference light intensity (Ir) is is detected the reference power detector (PDr) and the test light intensity (It) detected the test power detector (PDt) (for intensity test light (PDr) intensity (It) istest detected by the test power detector (PDt) (for intensity stability the resolution detector and the light intensity (It) is is detected byby the test power detector (PDt) (for intensity stability the resolution the power was chosen to 1and µW this study). Both are of the power detector was chosen to bedetector 1detector µW inwas this study). Both Irin are error-prone due toand a noise stability the resolution ofof the power chosen to bebe 1ItµW in this study). Both It It and Ir Ir are error-prone duetoto noise andunstable unstable source(i.e., (i.e.,variations variations laserof intensity relative the and unstable due source (i.e., variations in laser intensity relative to the duration usage), relative the expression error-prone a anoise and source ininlaser intensity totothe duration usage), the expression It/Ir would be used instead the purpose of noise-elimination. of It/Ir would be used instead for the purpose of be noise-elimination. Therefore, thisofsystem will present duration ofof usage), the expression ofof It/Ir would used instead forfor the purpose noise-elimination. Therefore, this system will present highly stable measurements. highly stable measurements. Therefore, this system will present highly stable measurements. Figure Experimental architecture. Figure 5. 5. Experimental architecture. Figure 5. Experimental architecture. Results and Discussions 4. 4. Results and Discussions 4. Results and Discussions 4.1. Experimental Results 4.1. Experimental Results This study proposed a method measuring small-angle variations detecting variations proposed method forfor measuring small-angle variations variations This study proposed aa method for measuring small-angle variations byby detecting thethe variations light intensity. The rotation the hexagonal mirror a small angle causes the laser beam intensity. Δθ causes the laser beam toto ofof light intensity. The rotation ofof the hexagonal mirror byby a small angle ∆θΔθ causes the laser beam to parallel shifted ΔZ (given in Equation (1)), and this affects the intensity (given in Equation (4)) bebe parallel shifted byby ΔZ (given in Equation (1)), and this affects the intensity (given in Equation (4)) ∆Z the light entering the PDt; therefore, the rotation angle Δθ can be determined the variations light entering the PDt; therefore, the rotation angle Δθ can bebe determined byby the variations ofof ofof the entering the PDt; therefore, the rotation angle ∆θ can determined by the variations the intensity. Figure showsthe theexperimental experimentalresults resultsof thetest testlight light intensity (It). Considerable the intensity. Figure (It). Considerable of the intensity. Figure6 66shows shows the experimental results ofofthe the test intensity (It). Considerable ◦ and ◦ , and variation (high sensitivity) light intensity observed between 0.6° and 1.2°, and there especially variation (high sensitivity) inin light intensity is is observed between 0.6° and 1.2°, variation (high sensitivity) in light intensity is observed between 0.6 1.2 there is is especially ◦ ◦ good linearity the range 0.75° and 1.1°; therefore, the ranges are used measuring small-angle good linearity inin the range 0.75° 1.1°; the ranges good linearity in the range ofof 0.75 and 1.1 ; therefore, are used forfor measuring small-angle variations. Figure 6 shows that the theoretical results are consistent with the measured ones. variations. Figure 6 shows that the theoretical results are consistent with the measured ones. variations. Figure 6 shows that the theoretical results are consistent with the measured ones. ◦ )). Figure 6. Intensity versus angle variation (Power (mW) – Δθ (°)). Figure 6.6. Intensity versus angle variation (Power (mW) − ∆θ ((°)). Figure Intensity versus angle variation (Power (mW) – Δθ 4.2. The Measurement Linearity and Reference Light Correction 4.2. The Measurement of of Linearity and Reference Light Correction Figure7 7depicts depictsthe therelationship relationshipbetween betweenthe theangle anglevariation variationand andthe theintensity intensityininthe thehighly highly Figure sensitive region Figure The highly sensitive region between 0.75° and 1.1° was adopted. Figure sensitive region ofof Figure 6. 6. The highly sensitive region between 0.75° and 1.1° was adopted. InIn Figure 7, 7, 2 2 a curve the linear regression showed the linearity the measurement was high = 0.9987). a curve ofof the linear regression showed the linearity ofof the measurement was high (R(R= 0.9987). Sensors 2016, 16, 1301 6 of 9 4.2. The Measurement of Linearity and Reference Light Correction Figure 7 depicts the relationship between the angle variation and the intensity in the highly sensitive region of Figure 6. The highly sensitive region between 0.75◦ and 1.1◦ was adopted. In Figure 7, a curve of 16, the1301 linear regression showed the linearity of the measurement was high (R2 = 0.9987). 6 of 9 Sensors2016, Sensors2016, 16, 1301 6 of 9 Figure versus angle angle variation. variation. Figure 7. 7. The The linear linear regression regression of of intensity intensity versus versus angle variation. This This reference reference correction correction system system (Figure (Figure 5) 5) enables enables the the simultaneous simultaneous detection detection of of the the test test and and This reference correction system (Figure 5) enables the simultaneous detection of the test and reference lights’ intensities. The correction is done by dividing the test light’s intensity by the reference lights’ intensities. The correction is done by dividing the test light’s intensity by the reference lights’ intensities. The correction is done by dividing the test light’s intensity by the reference reference light’s intensity. The left vertical axis of Figure 8 is the value of It/Ir. The right vertical axis is reference light’s The intensity. The left vertical axis 8ofisFigure 8 is of theIt/Ir. valueThe of It/Ir. rightaxis vertical is light’s intensity. left vertical axis of Figure the value rightThe vertical is theaxis ratio the ratio It/Ir multiplied by the stable-state intensity of the reference light (9 mW was the stable-state the ratio It/Ir multiplied by the stable-state intensity of the reference light (9 mW was the stable-state It/Ir multiplied by the stable-state intensity of the reference light (9 mW was the stable-state intensity intensity in which is for clarity of physical quantity. Figure 88 shows intensity in this this experiment), experiment), which for is added added for the the clarity of the thequantity. physicalFigure quantity. Figurethat, shows in this experiment), which is added the clarity of the physical 8 shows after 2 = 0.9985). that, after the reference correction, there was still good linearity (the linear regression, R 2 that,reference after the correction, reference correction, was still good(the linearity linear regression, R = 0.9985). the there was there still good linearity linear(the regression, R2 = 0.9985). Figure 8. Test light intensity divided by the reference light intensity for determining the small-angle Figure 8. Test light intensity divided by the reference light intensity for determining the small-angle regression curve. variation variation and and plotted plotted against against the the linear linear regression curve. 4.3. The Sensitivity and 4.3. The The Sensitivity Sensitivity and and Resolution Resolution ◦ in the ◦ The is superior to (mW/°) ∆power/ ∆θ) of architecture 0.6 The sensitivity sensitivity (S (S == Δpower/Δθ) Δpower/Δθ) of this this architecture architectureis issuperior superiorto to444(mW/ (mW/°)) in in the the range range of of 0.6° 0.6° to to ◦ ◦ inthe 1.2° 1.2 (mW/ therange rangeof of0.75° 0.75◦to to1.0° 1.0◦as asshown shownin inFigure Figure9. 9.If Ifthe thelaser laserhas hasgood good intensity intensity 1.2° and and to to 13 13 (mW/°) (mW/°))in in the range of 0.75° to 1.0° as shown in Figure 9. If the laser has good intensity and and the the detector detector is is of of aa high high resolution, resolution, the the sensitivity sensitivity and and resolution resolution for for the the measurement measurement of of angle angle variations can be improved. The relationship between Δθ and Δpower can be expressed as follows: variations can be improved. The relationship between Δθ and Δpower can be expressed as follows: power power power power(()) (6) (6) Sensors 2016, 16, 1301 7 of 9 and the detector is of a high resolution, the sensitivity and resolution for the measurement of angle variations can be improved. The relationship between ∆θ and ∆power can be expressed as follows: ∆θ = Sensors2016, 16, 1301 Sensors2016, 16, 1301 ∂θ ∂power (θ ) ∆power (6) 7 of 9 7 of 9 As revealed in Equation (6), ∆θ can be estimated by measuring ∆power. In addition, the resolution of this system [14,18,19] can be defined as power 1 err powererr err power powererr 1 (7) (7) err ∆power err power S 1S err power ∆θ = ∆powererr ∆θerr = (7) ∆power S The resolution resolution of of the the power power detector detector in in this this study study is is 11 µW. µW. The The maximum maximum and and minimum minimum The The resolution ofthe thesignal powererror detector in this study is1.4 1 µW. The maximum and minimum standardof the standard deviations of are 2.7 µW and nW. The average standard deviation standard deviations of the signal error are 2.7 µW and 1.4 nW. The average standard deviation of the −4° deviations of the signal are 2.7levels µW and nW.found The average standard of the to signal signal error is is 1.2 1.2 µW. The error resolution Δθ1.4 err are from Figure 10 deviation to be superior 10−4 signal error µW. The resolution levels Δθ err are found from Figure 10 to be superior to 33 ×× 10 ° − 40 error is 1.2from µW. The resolution levels ∆θ10 found from Figure 10 to to be 1.0°, superior to 3 × 10 They in can err−50are in the ranges 0.6° to 1.2° and 9.3 × in the ranges from 0.75° respectively. −50 in the 1.2° and9.3 9.3××10 10− 50 in the ranges rangesfrom from0.75 0.75° respectively. ◦ and ◦ to to ◦ , respectively. theranges rangesfrom from 0.6° 0.6◦ to to 1.2 in the 1.01.0°, TheyThey can can be evaluated by the reciprocal of the sensitivity (S) (Figure 9) and Equation (7) [19,20] at the average be evaluated by the reciprocal ofofthe (Figure9)9)and andEquation Equation [19,20] at average the average be evaluated by the reciprocal thesensitivity sensitivity (S) (S) (Figure (7)(7) [19,20] at the standard deviation deviation of of the the signal signal error error Δpower Δpowererr err = 1.2 µW. standard = 1.2 µW. standard deviation of the signal error ∆powererr = 1.2 µW. Figure 9. 9. The sensitivity sensitivity of experimental experimental architecture architecture (σ (σ is is 0.976). 0.976). Figure Figure The 9. The sensitivityof of experimental architecture (σ is 0.976). Figure The resolutionof of experimental experimental architecture (σ (σ is 0.976). Figure 10.10. The resolution architecture is 0.976). 0.976). Figure 10. The resolution of experimental architecture (σ is 5. Conclusions Conclusions 5. The proposed proposed hexagonal hexagonal mirror mirror architecture architecture can can be be used used to to measure measure small-angle small-angle variations variations in in aa The new and and simple simple method. method. Through Through the the observation observation of of the the light light intensity intensity variation, variation, the the angle angle variation variation new Sensors 2016, 16, 1301 8 of 9 5. Conclusions The proposed hexagonal mirror architecture can be used to measure small-angle variations in a new and simple method. Through the observation of the light intensity variation, the angle variation can be determined. The proposed design can be applied to detect reference light intensity and to eliminate the factors caused by the laser intensity variation, which would affect the precision of the measurement. The proposed structure is easy to assemble, low-cost, and highly stable. Based on these advantages, it can be effectively used to measure small-angle variations. The resolution and sensitivity are 3 × 10−40 and 4 mW/◦ in the angle interval of 0.6◦ , and 9.3 × 10−50 and 13 mW/◦ in the interval of 0.25◦ , respectively. Supplementary Materials: The supplementary materials are available online at http://www.mdpi.com/14248220/16/8/1301/s1, Hexagonal Mirror, Square Mirror. Acknowledgments: The authors thank Pin-ruei Huang, Yi-Chi Wang and Jiun-Hong Lin for their knowledge and mold manufacturing assistance on the optical system. The authors would like to thank the Ministry of Science and Technology of R.O.C., for financially supporting this research under contract no. MOST 104-2221-E-002-017. Author Contributions: Meng-Chang Hsieh designed the experiments; Meng-Chang Hsieh performed the experiments; Meng-Chang Hsieh and Jiun-You Lin analyzed the data; Chia-Ou Chang is the thesis advisor. All the three authors were engaged in writing this paper. Conflicts of Interest: The authors declare no conflict of interest. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Hsieh, M.-C.; Chiu, Y.-H.; Lin, S.-F.; Chang, J.-Y.; Chang, C.-O.; Chiang, H.-K. Amplification of the Signal Intensity of Fluorescence-Based Fiber-Optic Biosensors Using a Fabry-Perot Resonator Structure. Sensors 2015, 15, 3565–3574. [CrossRef] [PubMed] Wang, Y.; Liang, L.; Yuan, Y.; Xu, G.; Liu, F. A two fiber Bragg gratings sensing system to monitor the torque of rotating shaft. Sensors 2016, 16. [CrossRef] [PubMed] Hsieh, M.-C.; Lin, J.-Y.; Chen, Y.-F.; Chang, C.-O. Measurement of small angle based on a (1 0 0) silicon wafer and heterodyne interferometer. Opt. Rev. 2016, 3, 1–5. [CrossRef] Liu, Y.; Kuang, C.; Ku, Y. Small angle measurement method based on the total internal multi-reflection. Opt. Laser Technol. 2012, 44, 1346–1350. [CrossRef] Iwasaki, T.; Takeshita, T.; Arinaga, Y.; Sawada, R. Torque measurement device using an integrated micro displacement sensor. Sens. Mater. 2013, 25, 601–608. Xiao, X.; Gao, Y.; Xiang, J.; Zhou, F. Laser-induced thermal effect in surface plasmon resonance. Anal. Chim. Acta 2010, 676, 75–80. [CrossRef] [PubMed] Lin, J.-Y.; Liao, Y.-C. Small-angle measurement with highly sensitive total-internal-reflection heterodyne interferometer. Appl. Opt. 2014, 53, 1903–1908. [CrossRef] [PubMed] Zhang, S.; Kiyono, S.; Uda, Y. Nanoradian angle sensor and in situ self calibration. Appl. Opt. 1998, 37, 4154–4159. [CrossRef] [PubMed] García-Valenzuela, A.; Sandoval-Romero, G.-E.; Sánchez-Pérez, C. High-resolution optical angle sensors: Approaching the diffraction limit to the sensitivity. Appl. Opt. 2004, 43, 4311–4321. [CrossRef] [PubMed] Hogan, J.-M.; Hammer, J.; Chiow, S.-W.; Dickerson, S.-D.; Johnson, M.-S.; Kovachy, T.; Sugarbaker, A.; Kasevich, M.A. Precision angle sensor using an optical lever inside a Sagnac interferometer. Opt. Lett. 2011, 36, 1698–1700. [CrossRef] [PubMed] Xie, H.; Vitard, J.; Haliyo, S.; Régnier, S. Optical lever calibration in atomic force microscope with a mechanical lever. Rev. Sci. Instrum. 2008, 79. [CrossRef] [PubMed] Dixon, P.-B.; Starling, D.-J.; Jordan, A.-N.; Howell, J.-C. Ultrasensitive beam deflection measurement via interferometer weak value amplification. Phys. Rev. Lett. 2009, 102. [CrossRef] [PubMed] Yukita, S.; Shiokawa, N.; Kanemaru, H.; Namiki, H.; Kobayashi, T.; Tokunaga, E. Deflection switching of a laser beam by the Pockels effect of water. Appl. Phys. Lett. 2012, 100. [CrossRef] Chiu, M.-H.; Lee, J.-Y.; Su, D.-C. Complex refractive-index measurement based on Fresnel’s equations and the uses of heterodyne interferometry. Appl. Opt. 1999, 38, 4047–4052. [CrossRef] [PubMed] Sensors 2016, 16, 1301 15. 16. 17. 18. 19. 20. 9 of 9 Shiokawa, N.; Tokunaga, E. Quasi first-order Hermite Gaussian beam for enhanced sensitivity in Sagnac interferometer photothermal deflection spectroscopy. Opt. Express 2016, 24, 11961–11974. [CrossRef] [PubMed] Ok, G.; Choi, S.-W.; Park, K.H.; Chun, H.S. Foreign object detection by sub-Terahertz quasi-Bessel beam imaging. Sensors 2013, 13, 71–85. [CrossRef] [PubMed] Alda, J. Laser and Gaussian beam propagation and transformation. Encycl. Opt. Eng. 2013, 2013, 999–1013. Wang, S.-F. A Small-displacement sensor using total internal reflection theory and surface plasmon resonance technology for heterodyne interferometry. Sensors 2009, 9, 2498–2510. [CrossRef] [PubMed] Lin, J.-Y.; Chen, K.-H.; Chen, J.-H. Measurement of small displacement based on surface plasmon resonance heterodyne interferometry. Opt. Lasers Eng. 2011, 49, 811–815. Hsieh, M.-C.; Lin, J.-Y.; Chang, C.-O. Measurement of small wavelength shifts based on total internal reflection heterodyne interferometry. Chin. Opt. Lett. 2016, 14. Available online: https://www.osapublishing. org/col/abstract.cfm?uri=col-14-8-081202 (accessed on 15 August 2016). © 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).