Playground Safety: Applicable Standards, Guidelines and Protective

advertisement

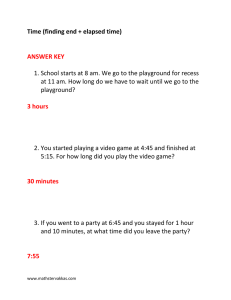

RISK CONTROL SERVICES : from Liberty Mutual Insurance Playground Safety: Applicable Standards, Guidelines and Protective Surfacing HIGHLIGHTS: • Adequate surfacing in a playground area will help reduce the likelihood of life-threatening injuries. • Installing wear mats under swings and slide exits helps reduce ground cover displacement • Consider marking equipment supports with a minimum fill level to aid in maintaining the original depth of material. Playground equipment can be found in a number of facilities: commercial child care, apartment complexes, parks and recreation areas, restaurants, hotels, schools and churches. With the number of play areas available, it is important that the owners or supervisors of these play areas take the time to inspect the equipment and grounds regularly. Inspection and maintenance are key ingredients to creating a safe area that children can freely play in without threat of harm. This document provides a high level overview of playgrounds from a safety perspective and outlines some of the things that should be watched and A playground at an elementary school considered regarding playground makes good use of landscape timber surfacing. When implementing a new for ground cover containment. playground surface, it is recommended that local jurisdictional requirements be researched, and a Certified Playground Safety Inspector (CPSI) be consulted in order to address specific issues. It is important that owners, operators and those who perform maintenance and inspections on these facilities have a good understanding of the following: • Applicable overall playground guidelines and standards. • Playground protective surfacing guidelines. • Identification of common hazards on playgrounds, including entrapment and impalement hazards. • Playground equipment “Fall Height” and “Use Zones.” • How to maintain and inspect playgrounds. • The importance of adequate signage and supervision. RC 8095 © 2013 Liberty Mutual Insurance – All Rights Reserved April 2013 Applicable Playground Guidelines and Standards The Consumer Product Safety Commission’s (CPSC) Public Playground Safety Handbook Publication 325 is a nationally recognized and commonly cited reference for voluntary playground safety guidelines and is a free download from the CPSC website. The American Society for Testing and Materials International (ASTM) offers another document, F1487 Standard Consumer Safety Performance Specification for Playground Equipment for Public Use, which is recognized as the national voluntary standard. This document is available for purchase from ASTM. Local Jurisdiction Information It is important to be aware of local jurisdictional requirements. Some states have adopted in whole or in part CPSC and/or ASTM requirements. For a general overview of individual state requirements, the International Playground Contractor’s Association (NPCAI) maintains a stateby-state summary at their web site. Certified Playground Safety Inspector (CPSI) The Certified Playground Safety Inspector (CPSI) Program is offered by the National Certification Board in coordination with the National Park and Recreation A community playground with no Association. Courses are offered to individuals certified appropriate ground cover underneath to inspect playgrounds for safety hazards and to ensure the swing sets. compliance with national standards set by the American Society for Testing and Materials (ASTM) and the Consumer Product Safety Commission. A professional must successfully pass the CPSI examination to receive the 3 year certification. An inspector with a CPSI certification can identify hazards on public playground equipment and ranks those hazards according to injury potential. A certified inspector can advise how to remove the hazards and establish a system of inspections and maintenance. The program is open to all interested in playground safety. For additional information about this program visit the NRPA’s website. Playground Protective Surfacing Guidelines Playgrounds should not be installed or operated without protective surfacing of some type. Concrete, asphalt or other hard surfaces should never be directly under playground equipment. Grass, dirt and compacted clay are not considered protective surfacing. Pea gravel, sand, shredded/recycled rubber mulch, wood mulch and wood chips along with material (including unitary surfaces) tested to ASTM F1292 standards are appropriate playground surface materials. CPSC’s Handbook Publication 325 Guide to Loose Fill Groundcover Depth Minimum Compressed Loose Fill Groundcover Inches of Loose Fill Material Protects to Fall Height (feet) 6* Shredded/recycled rubber 10 9 Sand 4 9 Pea Gravel 5 9 Wood Mulch 7 9 Wood Chips 10 *Shredded/recycled rubber loose-fill surfacing does not compress in the same manner as other loose-fill materials. However, care should be taken to maintain a constant depth as displacement may still occur. Loose-fill materials will compress at least 25% over time due to use and weathering. This must be considered when planning the playground. For example, if the playground will require 9” of wood chips, then the initial fill level should be 12”. RC 8095 2 Loose-fill surfacing requires frequent maintenance and measuring (See Figure 1) to ensure surfacing levels never drop below the minimum depth. Areas under swings and at slide exits are more susceptible to displacement; special attention must be paid to maintain these areas. Additionally, wear mats can be installed in these areas to reduce displacement. The perimeter of the playground should provide a method of containing the loose-fill materials. Consider marking equipment supports with a minimum fill level to aid in maintaining the original depth of material. Fall heights should be considered when applying fill to the play area. For instance, if the tallest piece of equipment measures 7’, it would take a minimum 9” of wood mulch protection to be considered safe. Figure 1: Illustrates ground cover measurement. Adequate surfacing is one of the most important factors in reducing the likelihood of life-threatening injuries. However, some injuries from falls, including broken limbs, may occur no matter what playground material is used. Applicable Definitions Fall Height: the vertical distance between the highest “designated play surface” on a piece of equipment and the protective surfacing beneath it. Designated Play Surface: any elevated surface for standing, walking, crawling, sitting or climbing, or a flat surface greater than 2” wide by 2” long, having an angle less than 30° from horizontal. Loose-Fill Surfacing Material: a material used for protective surfacing in the “use zone” that consists of loose particles such as sand, gravel, engineered wood fibers, or shredded rubber. Figure 2: Illustrates wear mat at the foot of a slide chute. Use Zone: is the surface under and around a piece of equipment onto which a child falling from or exiting from the equipment would be expected to land. These areas are also designated for unrestricted circulation around the equipment. Unitary Surfacing Material: a manufactured material used for protective surfacing in the “use zone” that may be rubber tiles, mats or a combination of energy absorbing materials held in place by a binder that may be poured in place at the playground site and cures to form a unitary shock absorbing surface (see Figure 2). References Consumer Product Safety Commission’s (CPSC) Public Playground Safety Handbook Publication 325. The illustrations, instructions and principles contained in the material are general in scope and, to the best of our knowledge, current at the time of publication. No attempt has been made to interpret any referenced codes, standards or regulations. Please refer to the appropriate code-, standard-, or regulation-making authority for interpretation or clarification. Provided that you always reproduce our copyright notice and any other notice of rights, disclaimers, and limitations, and provided that no copy in whole or in part is transferred, sold, lent, or leased to any third party, you may make and distribute copies of this publication for your internal use. © 2013 Liberty Mutual Insurance. All rights reserved. RC 8095