Fluke Presents

advertisement

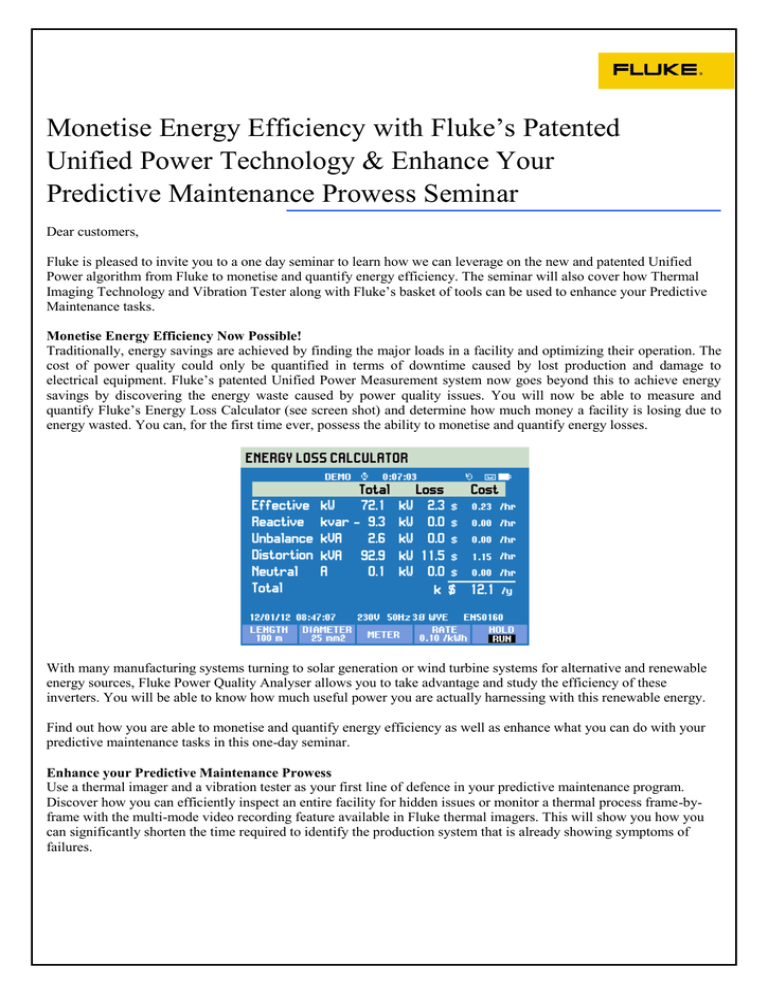

Monetise Energy Efficiency with Fluke’s Patented Unified Power Technology & Enhance Your Predictive Maintenance Prowess Seminar Dear customers, Fluke is pleased to invite you to a one day seminar to learn how we can leverage on the new and patented Unified Power algorithm from Fluke to monetise and quantify energy efficiency. The seminar will also cover how Thermal Imaging Technology and Vibration Tester along with Fluke’s basket of tools can be used to enhance your Predictive Maintenance tasks. Monetise Energy Efficiency Now Possible! Traditionally, energy savings are achieved by finding the major loads in a facility and optimizing their operation. The cost of power quality could only be quantified in terms of downtime caused by lost production and damage to electrical equipment. Fluke’s patented Unified Power Measurement system now goes beyond this to achieve energy savings by discovering the energy waste caused by power quality issues. You will now be able to measure and quantify Fluke’s Energy Loss Calculator (see screen shot) and determine how much money a facility is losing due to energy wasted. You can, for the first time ever, possess the ability to monetise and quantify energy losses. With many manufacturing systems turning to solar generation or wind turbine systems for alternative and renewable energy sources, Fluke Power Quality Analyser allows you to take advantage and study the efficiency of these inverters. You will be able to know how much useful power you are actually harnessing with this renewable energy. Find out how you are able to monetise and quantify energy efficiency as well as enhance what you can do with your predictive maintenance tasks in this one-day seminar. Enhance your Predictive Maintenance Prowess Use a thermal imager and a vibration tester as your first line of defence in your predictive maintenance program. Discover how you can efficiently inspect an entire facility for hidden issues or monitor a thermal process frame-byframe with the multi-mode video recording feature available in Fluke thermal imagers. This will show you how you can significantly shorten the time required to identify the production system that is already showing symptoms of failures. Learn how you can switch between focus-free and manual focus with one finger with Fluke’s revolutionary IROptiFlexTM focus system to help you perform industrial, electrical and mechanical inspections significantly faster than before. The industry’s first point-and-shoot IR-Fusion technology camera gives aligned digital and infrared images to help you determine and diagnose problems faster and easier. For years, technicians struggled to decipher machine vibration - an early sign of mechanical failure - using a dowel, a screwdriver or a stethoscope. While widely used, these solutions require a trained ear and often do not identify the root cause of a mechanical condition, leaving maintenance teams guessing and unable to make the right repair decisions. Many maintenance teams simply need fast and actionable answers. Typical vibration analyzers and software are intended for monitoring machine condition over the longer term, but they require special training and investment that may not be possible in many companies. Find out how you are able to troubleshoot mechanical problems and quickly understand the root cause of equipment condition without the need for sophisticated equipment. Together with the Power Quality Analyzer (PQA), you can locate, predict, prevent and trouble-shoot power quality problems in three-phase and single-phase power distribution systems. Using the advanced PowerWave function in PQA, you will be able to continuously capture waveforms for voltage and current within the specified time, and display on screen in high detail. You are also able to derive the power waveform from the data. The PowerWave feature is particularly useful if you are testing standby generation systems and UPS systems where reliable switch-ons can be vital. Through real-life applications and case studies, the interactive seminar will explore how Fluke tools can keep you powerful in your everyday job. There will be time set aside for demo and hands-on session to address the questions that you have. Outline of Seminar: Quantify energy losses with Fluke’s patented Unified Power Measurement Algorithm Monetise energy losses with Fluke’s Energy Loss Calculator Measuring the efficiency of inverters used in Renewal Energy Systems Inspect an entire facility for hidden issues or monitor a thermal process efficiently Troubleshoot mechanical problems and quickly understand the root cause of equipment condition without need for sophisticated equipment High speed data capture for motor and generator performance using PowerWave function Case study & applications Who should attend? Anyone and who wish to learn how to monetise and quantify energy efficiency Engineers who wish to test power inverters Electricians, utility, plant and mechanical maintenance, field and service technicians and engineers and consultants who perform thermal scanning, vibration monitoring, Power Quality analysis, troubleshooting & energy audit, plant and equipment maintenance. Professionals involved in evaluating performance of motor and generator like standby generation systems and UPS systems Details of seminar: Date: 18th Apr 2012 – Ho Chi Minh City, Vietnam 19th Apr 2012 – Vung Tau, Vietnam Time: 8:30 am – 12:00pm Location Ho Chi Minh City Venue: Ball Apollo Room - Liberty Central Hotel Address: 177-179 Le Thanh Ton – Dist 1, HCM http://libertycentralhotel.com/ Vung Tau Venue: DIC STAR HOTEL Address: 169 Thuy Van Str., Vung Tau city Web: http://www.dictt.com.vn/dicstar/ Fee Free! Speaker Biodata: Joseph Ong Joseph has a degree of Master in Information Technology from University of Newcastle with a Level II in Infrared Thermography and Level I Vibration Analysis. He is currently the Senior Product Consultant in Fluke South East Asia Pte Ltd. With more than 17 years of experience in pre-sales and post-sales application support on electrical and electronic testing instruments, Joseph is a very experienced trainer in power quality analysers and calibration equipment. So, don’t wait further. Sign up for this seminar now before seats run out. Best regards, Mr Yeo Cheng Ngee IG Sales Director Registration Form Fluke Energy Efficiency & PDM Seminar Country Venue Date Ho Chi Minh, Vietnam Liberty Central Hotel 18 Apr 2012 Vung Tau, Vietnam DIC STAR HOTEL 19 Apr 2012 For more information on this seminar, please feel free to contact us. Thank you. Yes, I / we will be attending the Fluke PDM & Optimising Energy Efficiency Seminar Participant Name ________ Designation Email ________ Direct Tel Participant Name ________ Designation Email * Contact Person __________________________ ________ ________ Direct Tel _________ ________ Designation Company _ ________ Address _________________ __ ________ Tel Fax __________________________________ Email Complete coupon and fax to (65) 6799-5577. Seats are allocated on a first-come-first-serve basis. * Please complete if contact person is different from participant’s name(s). Ms. Joanna Wong (65) 6799-5575 Email: Joanna.Wong@fluke.com Ms. Claryce Lim (65) 6799-5204 Email: Claryce.Lim@fluke.com ________