Section - 7 - All Tender

advertisement

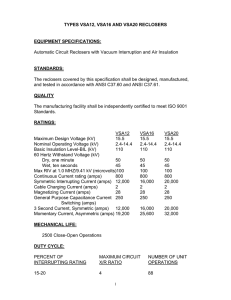

Section - 7 TECHNICAL SPECIFICATION OF 11KV Three Phase Automatic Circuit Recloser (ACR) 630A 11kv_acr_spc & gtp_ajgar_design2 1 Technical Specification of 11KV Three Phase Automatic Circuit Recloser (ACR) 630A 7.1 SCOPE: This standard covers the electrical, mechanical and performance requirements for three phase, automatic circuit reclosers for use on the overhead distribution system and in 33/11 KV, 5/6.67MVA Rural type substations. 7. 2 GENERAL: Reclosers furnished specifications shall conform in all respects to the requirements of this standard. These reclosers shall be suitable for use in a tropical climate with high relative humidity. The text, tables, figures and performances are part of this standard. This section of the document includes the design, manufacture, testing & inspection of 11kV ACR as specified. 7. 3 CLIMATE DATA: The equipments to be supplied against this tender shall be suitable for satisfactory use under the following climatic condition: Climate : Tropical, intense sunshine, heavy rain, humid. Maximum Humidity and Temperature sometimes occur simultaneously. Maximum Temperature 400 C : Minimum Temperature 030 C : Maximum yearly weighted average temperature 300 C : Relative humidity 50-100% : Annual mean Relative Humidity 75% : Average annual rain fall 3454 mm : Maximum wind velocity 200 km/ hour : 80 days/ year Average isokeraunic level : Maximum altitude above the sea level : Atmospherically, Mechanical and Chemical impurities : 300 metres Moderately polluted 11KV ACR as specified will be installed in tropical locations and in a hot humid environment with presence of the insects and vermin. The information is given as a guide for Tenders and no responsibility for its accuracy will be accepted, nor will any claim based on the above be entertained. 7. 3 SYSTEM PARTICULARS: Sl. no. 1. 3. 4. 5. 6. 7. 8. System Characteristics Voltage Level Normal System Voltage, kV Maximum System Voltage, kV System Frequency, Hz Phase Rotation (Anti-Clock wise) Type of System Grounding Rated Fault Level (3-Phase Symmetrical), MVA 3 sec. Basic Installation Level, kV 11kv_acr_spc & gtp_ajgar_design2 2 230 245 50 RST Solid 16300 132 145 50 RST Solid 6000 33 36 50 RST Solid 1500 11 12 50 RST Solid 500 750 650 170 75 7.4 RATINGS: Reclosers' shall have rating as defined in ANSI/IEEE Standard C37.60 (I) as summarised below: 4.1 a. b. 4.2 a. b. c. 4.3 4.4 4.5 4.6 4.7 4.8 Service Conditions: Temperature-up to 45°C. Altitude-up to 1,000 meters. Rated Voltage: Nominal system voltage-11,000volt Rated maximum voltage -15,000 volts. Power frequency withstand voltage-50 KV Rated frequency - 50 Hertz Rated minimum current shall be as shown in Table 1. Rated minimum tripping current shall be as shown in Table 1 with a tolerance of ± 5 percent. Rated symmetrical interrupting current shall be as in Table - I with asymmetrical relationships as defined in ANSI/IEEE C37.60. Rated symmetrical making current shall be the same value as the Rated symmetrical interrupting current, with asymmetrical relationships as defined in ANSI/IEEE C37.60. Rated minimum Impulse Withstand Voltage - 110 KV. 7.5 DESIGN: Design of the 11KV class III recloser shall be in accordance with ANSI/IEEE C37.60. The recloser shall be designed to provide self-contained distribution circuit protection with series trip, solenoid operation and electronic control single break contact structure and fault interruption under vacuum. The vacuum interrupters shall be in accordance with ANSI/IEEE C37.85. The recloser shall be accordance with ANSI/IEEE C37.85. The recloser shall be designed to sense line-toground, line-to-line or three-phase fault currents and interrupt all three phases of the distribution circuit simultaneously. The recloser shall be equipped with a electronic type ground trip and sensitive ground trip feature. For fault target, Automatic Circuit recloser will be provided with an indicator for detection of fault current on individual phase or ground. If the Electronic Control cubicle of Reclosers or Recloser itself require an auxiliary transformer, the manufacturer must provide the same at his cost. The recloser shall be provided with in-built auxiliary transformer of required rating to provide power supply to the control panel. 7.6 DESIGN FEATURES ARE SUMMARISED BELOW: The Recloser head shall be fabricated of corrosion resistant materials or provided with an impact and corrosion resistant finish and should also be suitable for storage in uncovered areas and shall be provided with the following features: 1. a: Universal clamp type terminals which will accept #6 AWG to 350 MCM copper or aluminium conductors either horizontally or vertically. In place of universal clamp insulated and water blocked cable tails of proper voltage and current rating is acceptable. 11kv_acr_spc & gtp_ajgar_design2 3 b: c: d: e: f: g: h: i: j: 2 a) b) c) 03 Wet process polymer bushings with bushing clamps bolted to head with bird guard protection to provide a fully insulated bushing arrangement. Lifting strap designed to lift the entire recloser and to lift the head and operating mechanism, so positioned that the recloser will remain vertical when lifted. Manual Operating Provision: Recloser shall be provided with a manual operating lever, which is suitable for operating with a hot stick or other suitable manual operating means. Non-reclosing lever/feature to set recloser to lock out after one operation. Counters: An operation counter shall be provided to indicate the total number of operations of the recloser. The counter shall be visible with recloser in service. Attachment clamps and an "o-ring" seal to fix tank to head in such a manner as to provide a positive, moistureproof seal. Closing tool port for manually closing de-energized recloser, provisions should be made for manually closing de-energized recloser without un-tanking it. A manual closing tool shall be provided with each recloser. Alternatively closing and tripping by LV solenoid and control cubicle is acceptable. Nameplate (s) listing factory ratings and settings of the recloser, with provisions for changing of nameplate data when field changes are made affecting operating characteristics of the recloser. Nameplate information shall include, but not be limited to the following: Manufacturer's Identification Contract number and IFB number Recloser type Recloser serial number. Rated maximum voltage Rated continuous current. Rated tripping current. Rated symmetrical interrupting current. Rated impulse withstand voltage. Number of fast operations & also identification of Operational Curve. Number of slow operations & also identification of Operational Curve Total operations to lock-out. Designation of operating curves. BIL Rating. Nominal system voltage. Year of manufacture. The recloser tank shall be fabricated of corrosion resistant steel, and provided with an impact and corrosion resistant finish and should also be suitable for storage in uncovered area and provided with a mating surface for the head so that leaks will not occur and that the recloser will remain mechanically operable at the maximum operating pressure generated by normal operation of the recloser. The tank shall have the following features: Mounting lugs for mounting the recloser in a substation frame or cross arm mounting hanger. Ground connector to accept #8 to #2/0 AWG copper or aluminum conductors. The finish shall be a thermosetting impact and corrosion resisting, acrylic paint (ANSI Colour # 70) over inhibiting epoxy prime coat. Provision shall be made for personnel to readily check the insulating gas pressure with the recloser energized. 11kv_acr_spc & gtp_ajgar_design2 4 4 5 6 7 8 9 10 Indicator markings shall show the safe operating ranges of pressures. The electronic ground trip device shall be self-contained and independent. 11 KV three phase recloser shall be equipped with multi - ratio current transformers for the purpose of metering and protection. The recloser shall be provided with multifunction meter to read the following parameters: ampere, voltage, KW demand, KVAR, KWH and Power factor. The protection C.T. shall cover the entire protection range of the device. Protection setting through the full range of the device should be programmable without changing the CTs. Minimum ground fault current at 11 KV bus is approximately 50amps. So the time current characteristic curve for ground tripping must be rational with the phase current tripping and minimum line to ground fault, current. The minimum phase or ground trip currents should be changeable externally in the control cubicle or in the electronic panel or by changing the CT ratio. Bidder should supply minimum three (3) copies of catalogue showing the exploded view of each type (s) of equipment along with part numbers so that each component can be identified. With each equipment one (1) copy of the operational manual should also be supplied. Lock washers - all -electrical connections, bushing mounting bolts and coyer attachment bolts require lock washers. Lock washers shall be fabricated from materials that comply with the requirements of ANSI 1318.21.1. Substation Mounting frame - The three - phase reclosers shall be mounted in a height - adjusting mounting frame to maintain a minimum ground distance of two hundred seventy five centimeters (9') to live parts and two hundred forty four centimeters (8') to any bushing porcelain above the concrete foundation. The mounting frame shall be made of steel to provide a sturdy, stable foundation for the recloser and be complete with provisions to secure the frame to the recloser concrete foundation plus secure the recloser to the mounting frame. The substation mounting frame shall have provisions to mount a recloser tank lowering windless compatible with substation mounting frame. For grounding purposes, all redoser mounting frames are to be drilled for two 1.42875 centimeters (9/16") round holes spaced on 4.445 centimetres (1.75") centres and located on opposite corner legs 30.48 centimetres (1') from the bottom of the frame. The mounting frame shall be hot dipped galvanized after fabrication. The battery for operating the Recloser’s components and control should be easily replaceable. Bushing should be Polymer Type. Related software & accessories for ACR is within the scope of supply. 7.7 OPERATION CHARACTERISTICS: 1. 2. a. Operation - 11 KV Class III recloser shall be capable of sensing and interrupting fault current within the range of its maximum trip and maximum interrupting ratings. For permanent faults, the recloser shall lockout after two, three or four operations depending on the control settings Operations depending on the control settings. Operation of a typical class III recloser with four operations (two fast and two slow) to lock-out. Co-ordination- Class III 11 KV recloser shall have dual time-current capability. They shall have capability for field adjustment and selection of alternative curves (Standard inverse, very inverse or extremely inverse) in order to properly coordinate with the source relay characteristics curve sequence of operation and number of operations to lock-out. The recloser shall be capable of field adjustment to co-ordinate with the (I) 11 KV line recloser, (2) 33KV power fuse. Beginning at the 33 KV source in the direction of the 11 KV load, the arrangements is as follows: 33KV power fuse, substation power transformer, class III 11 K V recloser. Load side (11KV) - In the 11 KV distribution system there are different sizes of 11 KV line recloser from 11kv_acr_spc & gtp_ajgar_design2 5 b. c. d. 3. a. b. c. 4. 5. different manufacture. The 3 phase class III 11 KV, 3 phase reclosers must trip and lock - out later than 11 KV line reclosers, which may be set for two fast curve and two delayed curve operations to lock-out. Between the fast and slow operations there must be sufficient time delay to allow for operation of fuses. Source side (33KV) - the substation is 33/11 KV delta-wye. 100E standard speed fuses are installed in the 33KV source side of the substation, Class III 11KV 3 phase reclosers must trip to lock-out faster than the minimum melting time of the indicated power fuse. The class III-11KV reclosers must trip to lock-out before the 33KV fuse For bid evaluation, each supplier must furnish drawings showing proposed recloser time-current characteristics of operating curves. Number of Operations - Factory settings for phase and ground trip operating sequences shall be as given in Table 1. Class III reclosers shall have provision for field adjustment to provide the following options on either phase or ground trip: Number of fast operations - one, two, three or four. Total operations to lock - out, two; three or four. Non-reclosing features - operable by external lever or provision in electronic control to provide one operation to lockout without reclosing. Reclosing Interval - Adjustable from 0.6 to 1000 seconds. Reset Time: The reset time of the reclosers should be variable from 2 seconds to 120 seconds. 7.8 STANDARDS: TABLE 1 CURRENT RATINGS AND OPERATING SEQUENCES STANDARD - CLASS III, 11 KV THREE PHASE RECLOSERS Rated Symmetrical Interrupting Capacity Amps 12,500 Minimum Trip Amps Variable from 50 to 630 Phase trip Number of Operations Fast Slow Curve Curve 0-4 0-4 Ground trip Minimum Trip Amps Variable from 50 to 630 7.9 INFORMATION REQUIRED: The Tenderer/ Manufacturer as per tender requirements shall provide all information. Besides these, the following information/Documents has to be submitted along with the tender:(a) Manufacturer’s drawing showing Outline dimension, Cross-sectional & General arrangement drawings of offered type equipment with mounting structure arrangement. (b) Manufacturer’s Printed Catalogue describing specification and technical data of the offered type equipment. (c) The Tenderer/Manufacturer shall submit with the bid the testing procedure & list of testing/measuring equipment, meters etc. used for Factory test witness. (d) Construction, Installation, Operation & Maintenance Manual. (e) Manufacturer's valid ISO Certificate. 11kv_acr_spc & gtp_ajgar_design2 6 7.10 DOCUMENTATION: The following documents are to be submitted along with the Tender for the similar or higher rating of same ACR otherwise the bid will be rejected: A. C OMMERCIAL Tenderer shall be eligible as per ITT Clause No. 4 and they should submit Bid validity, Bid Bond, Bid Bond validity, Price Schedule, Delivery Schedule, Authorisation of the signatory, Tender Submission Sheet, Tenderer Information Sheet & Documentary evidence for establishing the Tenderer’s Qualifications, etc. and all other documents including information related to rejection clause as per Tender Document. B. TECHNICAL 1) Guaranteed Technical Particulars (GTP) shall be properly filled up and signed by both Manufacturer & Tenderer; 2) Letter of authorization from the Manufacturers, in case, the Bidder is not the manufacturer, in prescribed Form; 3) Minimum 02(Two) nos. of Manufacturer’s Supply record for similar or higher Ampere rating of same voltage class of offered type 11KV ACR within the last 5 (five) years from the date of tender opening in the following format (The supply record covering at least 25% of the total offered amount/ tendered quantity in a single contract will be considered only): Sl. No. Name, Address, Phone No., email & Fax No. of the Purchaser Contract No. & Date Contract Value Description of Material with Quantity Date of Completion of Supply 4) Satisfactory Performance Certificates from at least 2 (two) Electricity Utility for similar or higher Current rating of same voltage class of offered Model/Type 11kV ACR at least 3(three) years operation within the last 5 (five) years from the date of opening. 5) Type Test Reports (as stated in Clause 7.11) for similar or higher current rating of same voltage class of offered Model/Type of 33kV ACR from KEMA, Netherlands; CESI, Italy; CPRI, India; ASTA, China; China Electric Power Research Institute (CEPRI), China; KERI, Korea as per relevant Standards (unless otherwise specified). 6) 7.11 Outline and General Arrangement drawings of the offered type ACR. TEST REPORTS: The following test reports along with test results for the similar or higher current rating of same voltage class, offered Model/Type 11kV ACR in accordance with the Latest version of ANSI/IEEE C37.60 standard, which are issued by an approved, internationally acknowledged, reputable independent testing laboratory or Institute by confirming design to the tender document shall be submitted with the offer. Design tests shall be carried out by the manufacturer from KEMA, Netherlands; CESI, Italy; CPRI, India; ASTA, China; China Electric Power Research Institute (CEPRI), China; KERI, Korea in accordance with Section 6 of ANSI/IEEE C37.60. The Manufacturer shall submit certified copies of design test reports along with bid document. Design tests on II KV Class III reclosers shall include, but not be limited to, the following: 11kv_acr_spc & gtp_ajgar_design2 7 a. b. j. k. l. m. n. o. p. j. k. Impulse withstand voltage test Power frequency withstand voltage test Interruption tests Making current tests. Minimum tripping current tests. Radio influence voltage tests. Temperature rise test. Time-current tests. Mechanical operations test. Transformer magnetising current interruption test. Simulated surge arrester operation test. Production tests shall be carried out by the manufacturer in conformity with the latest revision of Section 7 of ANSI/IEEE C3 7.60. The manufacturer shall submit certified copies of production test reports. Production tests on 11 KV Class III reclosers shall include, but not be limited to, the following: a. Calibration test. b. Control, secondary devices and accessory devices tests .. c. Dielectric withstands test -1minute dry, low frequency. d. No load operating test. e. Mechanical operations test. 7.12 TEST REPORT: The Bidder shall furnish the following type test reports as per latest revision of ANSI/IEEE C37.60 standard, which are issued by an approved, internationally acknowledged, reputable KEMA, Netherlands; CESI, Italy; CPRI, India; ASTA, China; China Electric Power Research Institute (CEPRI), China; KERI, Korea by confirming design to the tender document with his bid proposal for each size and Class of recloser otherwise the bid will be rejected. a. b. c. d. 7.13 Symmetrical interrupting current. Impulse withstands voltage. Power frequency withstand voltage at 60 seconds: Time current curves of the recloser phase and ground trip plotted to the same ·scale. The curves shall be based on tests conducted at 25° C. SPARE PARTS: The bidder shall include separately with his offer a list of manufacturer's recommended spare parts for two (2) years operation per unit price quoted for each of the items. The cost of spare parts will not be considered in the tender evaluation. The purchaser reserves the option of purchasing any or all of the spare parts listed. 7.14 OTHER STANDARDS: The dimensional and performance requirements of the 11 KV Class III recloser based on other internationally recognized standards are acceptable only if the requirements of such standards are equivalent to or exceed the requirements quoted in this document. As co-ordination with other reclosers and sectionalizing devices is critical for protection of the distribution systems, the standards in this document covering operating characteristics shall be strictly adhered to. 11kv_acr_spc & gtp_ajgar_design2 8 BIBLIOGRAPHY OF REFERENCED STANARDS (Latest Edition) : 1: 2: 3: 4: 5) 6. ANSI/IEE C37.60, American National Standard for Overhead, Pad- Mounted, Dry Vault and Submersible Automatic Circuit Reclosers and Fault Interrupters for AC Systems. ASTM 03487, Standard Specification for Mineral Insulating Oil Used in Electrical Apparatus. ANSIC57. 13 American National Standard for Instrument Transformers. ANSI B 18. 21.1, American National Standard for lock washers. C37.61 American National Standard guide for the application operation & maintenance of Automatic Circuit Recloser. Equivalent Standard. 7.15 APPROVAL OF DRAWINGS & SPECIFICATIONS: Design & Drawing, Specification, Features & Accessories, Guaranteed Technical Particulars (GTP) and Manufacturer’s Printed Catalogue describing specification and technical data of offered Model/Type 11KV ACR shall be submitted to the Engineer, Director, Design & Inspection–II, BPDB by the Bidder for approval, prior to the manufacturing of the goods. The Bidder shall have to submit 3 (three) sets of the same for approval within 15 days from the date of signing the Contract. 7.16 TESTS AT MANUFACTURERS WORKS General Functional electrical, material, mechanical and hydraulic tests shall be carried out at manufacturers’ premises. The extent and method of recording the results shall be agreed by the Purchaser in ample time to enable the tests to be satisfactorily witnessed or to make any changes to the proposed program of tests. Material Tests The supplier shall provide test pieces free of charge as required to enable the quality of the material to be determined at the supplier’s expense. Purchaser may at its own discretion and by specific arrangement accept certified particulars of tests carried out in the absence of his authorized representative. Type Test Type tests are required to prove the general design of the offered equipments/ materials. The Tenderer shall submit the type test reports of the offered equipments/ materials from internationally reputed independent testing laboratory as per latest version of relevant IEC/ BS or ANSI/IEEE C37.60 standards as mentioned in the tender. Routine Tests All equipments/ materials shall be subjected to routine tests as per latest version of relevant IEC/ BS or equivalent international standards as mentioned in the contract at the manufacturers works and shall include, but not be limited to, an operational test. 7.17 Technical Orientation and Quality Test Witness The Purchaser shall have the right to inspect/test the goods/materials to confirm their conformity with the specification. The purchaser shall be entitled at all reasonable time during manufacture to inspect, examine and test of goods/materials at the manufacturers’ premises, workmanship and performance. 11kv_acr_spc & gtp_ajgar_design2 9 The Routine test shall be carried out as per latest version of relevant IEC/ BS or ANSI/IEEE C37.60 standards as mentioned in the contract at the manufacturer premises or other places where the test facilities are available. The Supplier shall, after consulting the purchaser, give notice to the Purchaser in writing of the date and the place where the material or equipment will be ready for quality witness testing. When the purchaser intends to attend the test he shall promptly inform the supplier accordingly in writing, so that he can take action. The purchaser shall give the supplier timely notice in writing of his intention to attend the test. Where the supplier provides for tests on the premises of the supplier or of any manufacturer of the supplier, except where otherwise specified, shall provide free of charge such assistance, labor, materials, electricity, fuel, stores, apparatus and instruments as may be requisite and as may be reasonably demanded to carry out such test efficiently. These tests shall be performed as per latest version of relevant IEC/ BS or ANSI/IEEE C37.60 standards as mentioned in the contract and only routine tests as agreed upon, will be performed. As and when the purchaser is satisfied that any materials/ equipments have passed the tests referred to in this clause, purchaser shall notify the contractor in writing to that effect. Should any inspected/ tested goods fail to conform to the specification, the Purchaser shall have the right to reject any of the items or complete batch if necessary. In that case Supplier has to replace the equipment and to make good of them and the supplier shall conduct similar pre-delivery Inspection and factory tests without any financial involvement to the purchaser. In case any of the Equipment found not conforming to the specification at the time of post landing Inspection, the supplier will in no way be relieved from the responsibility of replacing them on making them good at their own cost, despite the Equipment were found good at the time of Factory Acceptance Test. Nothing in this clause shall in any way release the supplier from any warranty or other obligations under the contract. If the offered goods are manufactured outside the purchaser’s country then BPDB’s Inspection Team shall have to conduct Technical Orientation and Quality Test Witness at the manufacturer’s factory premises. The cost incurred for this purpose shall be borne by the contractor and the cost in this regard shall be deemed is included in the offered price. The cost of Air Tickets (both way) from Bangladesh to Manufacturer’s Country (place of Technical Orientation and Quality Test Witness), Hotel Accommodation etc. will be borne by the Supplier. Other than this, the Supplier will pay a standard amount of pocket money per day (excluding journey period). The period for this purpose is more or less 07 (seven) days (excluding travel period). All the cost for this purpose shall be deemed to be included in the offered price. No goods shall be packed, prepared for shipment/delivery unless it has been approved including factory Test reports and written instructions have been issued by the Purchaser. 11kv_acr_spc & gtp_ajgar_design2 10 7.14 POST-LANDING INSPECTION AND TESTING : The Supplier shall inform the purchaser immediately after arrival of the goods at the designated store of BPDB (as per delivery schedule). An Inspection team of BPDB shall perform the post-landing inspection in presence of supplier's representative. The Supplier shall arrange the program of post-landing inspection. Any defect or damage found at post-landing inspection, the defective or damaged materials/ goods to be replaced by the supplier at his own cost within the stipulated time. The purchaser’s right to inspect, test (where necessary) and reject the goods after delivery at the designated store of BPDB shall in no way be limited or waived by reason of the goods having previously been inspected, tested and passed by the purchaser prior to the good's delivery. The Inspection team will check the physical conditions and quantity of the goods delivered. If necessary, the inspection team will select the sample of good(s) and sent the selected sample goods to CERS, BPDB or BUET/ CUET/DUET/ KUET /RUET (as selected by the inspection team) to carryout the test(s) as per contract to confirm the conformity to the approved Technical Specifications, Guaranteed Technical Particulars (GTP), drawings and relevant standards. If the tested sample(s) fail to confirm the specifications in tests, the full consignment will be rejected. All cost of testing of Materials/ Goods including carrying, loading, un-loading etc. will be borne by the supplier. 11kv_acr_spc & gtp_ajgar_design2 11 Section - 8 GUARANTEED TECHNICAL PARTICULAR's of 11 KV AUTO CIRCUIT RECLOSERS (630A) 11kv_acr_spc & gtp_ajgar_design2 12 TECHNICAL PARTICULARS & GUARANTEES OF 11 KV AUTO CIRCUIT RECLOSERS (To be filled up by the Manufacturer in the Manufacturer Letterhead Pad with appropriate data) SL. Manufacturer’ guaranteed Description BPDB Requirement No. technical particulars 1 Manufacturer’s name and Address To be mentioned 2 3 Country of Origin Type and Model Reference/Design standard(BS/IEC or ANSI/IEEE C37.60) Catalogue no. of proposed item Interrupting medium Control System Ground trip mechanism Insulating Medium Nominal System voltage Maximum Voltage BIL Rated Frequency Power frequency withstand voltage Rated Continuous Current Maximum Rated Current Symmetrical Interrupting Current Symmetrical Making Current To be mentioned To be mentioned 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 To be mentioned To be mentioned Vacuum Electronic Electronic SF6/ Vacuum Type 11 kV 15 kV 110 kV 50 Hz 50 kV 630 Amps 630 Amps 12,500 Amps 31,250 Amps Phase : 50 ~ 630 Amps Rated Minimum Tripping Current Ground : 50 Amps Break Contact Structure Single Break No. of fast Operation 0 to 4 No. of delayed operation 0 to 4 1,2,3 or 4 (depending No. of operations to lockout on setting) Adjustable 0.6 to 1000 Reclosing Time Interval sec Resetting time Adjustable 2 ~ 120 sec Provision for three phase Amp. Ammeter for phase Measurement current measurement To be mentioned Co-ordination Capability (TCC standard inverse, very Curves) inverse and extremely inverse curve Corrosion resistance Recloser Head material 11kv_acr_spc & gtp_ajgar_design2 13 SL. No. Description 29 Recloser tank 30 Recloser bushing 31 Operations Counter 32 33 34 35 36 Gas pressure indicator 38 Sub-station Structure/frame 39 Design & Product test 41 42 43 44 45 46 Manufacturer’ guaranteed technical particulars Corrosion resistance steel Polymer bushing with bird guard Shall indicate total operation Manual Operating Provision & Shall be provided Lockout Indicator Protection & Metering CT ratio To be mentioned Universal clamp to accommodate 6 AWG to Connector 350 MCM Cu or Aluminum Provision for different trip Without changing CT’s current setting or without untanking 10 meter control cable Cable for control/meter box shall be provided 37 40 BPDB Requirement Shall be included mounting Shall be submitted as per tender Fault Locator feature(in control panel) Capacitor Voltage Divider Input available Battery Nominal Voltage Nominal Capacity(Ah) of Battery Self discharge Time(Battery) Shall be provided Versus Service Life Time(Battery) Auxiliary Input Voltage Yes/No Yes/No To be mentioned To be mentioned To be mentioned To be mentioned 220 V Manufacturer’s seal & signature 11kv_acr_spc & gtp_ajgar_design2 Bidder’s seal & signature 14 8.02. SCHEDULE OF MANUFACTURER’S NAME AND PLACES OF MANUFACTURE & TESTING Item No Description Manufacturer's Name Lot-1 33 AUTOMATIC CIRCUIT RECLOSER (ACR) 800A Lot-2 11 AUTOMATIC CIRCUIT RECLOSER (ACR) 630A 11kv_acr_spc & gtp_ajgar_design2 15 Place of Manufacture Place of Testing & Inspection 8.03. SCHEDULE OF PROPOSED STANDARDS IN WHICH TRANSFORMERS & PANELS SHALL BE PROVIDED The Bidder shall indicate the standard to which the materials offered by him conform to. Should these standards differ from the specified standard in any respect the Bidder shall detail the differences between the proposed and specified standard. Item No Description Standard Lot-1 33 AUTOMATIC CIRCUIT RECLOSER (ACR) 800A Lot-2 33 AUTOMATIC CIRCUIT RECLOSER (ACR) 630A 11kv_acr_spc & gtp_ajgar_design2 16 Section - 9 DRAWINGS To be submitted by the Bidder 11kv_acr_spc & gtp_ajgar_design2 17