A Compact 500 KV/50 ns High Voltage Resistive Probe with High

advertisement

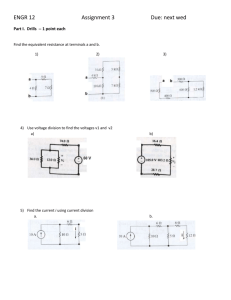

Pulsed Power Technology A Compact 500 KV/50 ns High Voltage Resistive Probe with High Division Ratio S.J. Mousavi, G.H. Rahimi, H. Khadem Kalan, J. Safaee, and M. Barati Electronic and Communication Research Center, Majdzadeh, Tehran, 1355874541, I.R. IRAN Phone :+9 8(021) 55765748, E-mail: mousavi314@gmail.com Abstract – Resistive probes have been developed for fast rise time, high voltage measurements in many pulsed power applications. This paper describes the design, construction, calibration and testing of a fast rise time resistive high voltage probe. Physically, the compact probe consists of two stages. The first stage is the liquid resistor portion which is responsible for the majority of the division ratio. The second stage of the divider is composed of discrete high frequency resistors in a small, electrically shielded box. The probe is calibrated in time-domain and frequency domain precisely. The frequency response of the probe was extracted by a network analyzer using a novel technique. The time domain calibration is done by using a homemade 2 kV/50 ns pulser with a standard Pintek HV-39pro (40 kV/220 MHz) probe. The resistive probe can easily capture a voltage pulse of 500 kV/50 ns generated by a Marx generator through a dummy load and then it decrease the high voltage pulse with high enough division ratio (14000) for sampling oscilloscope without any distortion or high voltage problem. details. The divider was calibrated through the 16 kv/50 ns Marx Generator (MG) by Pintek HV39pro probe. The divider could successfully capture the output pulse of MG without any distortion. The results of time domain calibration are in good agreement with 10 MHz bandwidths obtained from the frequency calibration. Finally, the divider proves its good performance in measuring of the 420 kv MG comparing by simulation result. 2. Principle and modeling A voltage divider can be easily constructed as a tube filled with a liquid resistive solution, with a top and bottom electrode (Fig. 1). An intermediate tap (a grid, plate, etc.) connects to the liquid solution and experiences only a fraction of the full voltage applied. The distance between the tap and the bottom electrodes sets the dividing ratio. The liquid column between tap (mid electrode) and ground is called lower arm, while the one between tap and HV electrode is called upper arm of the LRD. 1. Introduction Measurement of high voltage (HV), steep front, and short duration pulses has received considerable attention in many fields, such as pulsed gas lasers, pulsed x-ray generators and transients in power systems [l–3]. The most important instrumentation in high voltage measurements is the divider, as the magnitude of the voltage can vary from tens of kilovolts to hundreds of kilovolts. For practical purposes, not only extremely high division ratio but also wide bandwidth of the divider should be achieved simultaneously [3]. A liquid resistive divider (LRD) often is selected as its construction is relatively simple and it allows for high ohmic values. The frequency response of such a high impedance resistive divider is limited by its stray capacitances to the high voltage and ground terminals. This problem is usually allayed by field control, using electrode geometries chosen to make the electric field density almost constant along the resistor. Lengths of divider are important in this way because it shape the electric field. On the other hand, to obtain a divider with high ratio; LRDs must be constructed in long lengths. In this paper a two stage LRD which is consists of potassium dichromate solution with high division ratio and acceptable length is described. Furthermore, the overall structure of divider is depicted in HV Electrode Insulator Column Solution Mid Electrode (Tap) Ground Electrode Fig. 1. Simple liquid resistive divider (LRD) For a divider implemented as a vertical column, along all of its length, the product of the resistance and the capacitance between any two points (neglecting the inductance) is constant when it is compensated. Resistance variations due to temperature or concentration changes are reflected identically in lower and upper arm of LRDs and the division ratio is thus unchanged. The resistive and capacitive parts of both arms are balanced by their geometrical symmetry (i.e. by their inverse dependence from section and length). This 292 Oral Session means that even changes in the tube diameter along its vertical axis will not influence the divider balance. Use of two series divider which is called “two stage divider” is interested for increasing the division ratio. Fig. 2 demonstrate the circuit model of two stage divider. Actually, the second stage is constructed of low inductance resistors having good frequency response. First stage high specific heat, which exceeds that for metals by an order of magnitude; a high power; a rapid recovery of electric strength after an occasional breakdown; etc. 3.1. First stage The dissolved substance was used in LRD is potassium dichromate (K2Cr2O7). Referring to [4] Brass material was selected for electrodes as a compatible materials for potassium dichromate solution of LRD. Cross section of lower arm of LRD is shown in Fig. 3. Second stage Body Mid Electrode Ground Electrode Fig. 2. Circuit model of two stage LRD a Referring to [4] and concerning details mentioned above the circuit model of two stage divider can be extracted as shown in Fig. 2. Also, the value of elements can be estimated as below: l l RHV HV ; RLV LV ; A A CHV 0 A A ; CLV 0 , dHV dLV (1) in which: lHV dHV is the length of high voltage arm; b lLV dLV is the length of lo voltage arm; Fig. 3. Lower arm cross section of LRD (a); structure dimension (b) A is the iameter of LRD; is the resistivity of liquid solution; ε is the permittivity of solution. The division ratio (DR) of this model could be evaluated as follow: RLV R2 (2) DR . RLV RHV R1 R 2 According to Eq. (2), the division ratio is affected by lower and upper arm lengths. Decreasing the lower LV arm length and increasing the higher HV arm length, both lead to the more division ratio. In practice, decreasing of LV arm length to a few millimeters is difficult. In addition, increasing of HV arm could be result in long structure. 3. Overall structure It is preferable to use mixtures of salts and acids solution as elements with active electrical resistances in pulsed power. Their considerable characteristics are as follows [4]: a high electric strength of solutions (up to 300 kV/cm for a microsecond pulse duration); a high electric energy dissipated in a unit mass because of the In this figure, the housing cover is made of polyamide material. By the special shape of the ground electrode support we allow the bubbles to easily escape in the driver filling process. As shown in Fig. 3, the mid electrode is insulated from ground electrode by piece of Teflon substance. The LRD column is formed by centralizing two insulators tubes. Therefore, all (ground, mid and HV) electrodes are constructed in ringing shape to reduce the area of effective electrode surfaces and increase the total resistance of LRD. To achieve the acceptable ratio, the lengths of upper arm and lower arm was selected 25 cm and 2 mm respectively which leads to division ratio of 125. The choice of solution concentration was performed in order to achieve 5 kΩ total resistance in LRD. If the compact divider is interested the divider should be submerged in the transformer oil to avoid any unwanted flashover. In Fig. 3, b the dimensions of final structure is shown . 3.2. Second stage Output of first stage of LRD is fed to a low inductance 5.6 KΩ resistance as a upper element (R1 in Fig. 2) of 293 Pulsed Power Technology subsequent stage. Final output of LRD is transmitted to oscilloscope by 50 Ohm terminated RG-402 cable. To sum up, the total theoretical division ratio of LRD will be as follows : 5600 / 50 125 –1 line fixture was associated with LRD. As demonstrate in Fig. 7, the cut-off 3 dB frequency is around 10 MHz. 14000–1. CH2 4. Calibration CH4 After assembling, we calibrated the LRD with the standard 40 kV/220 MHz HV_39pro probe manufactured by Pintek, and a Tektronix 2 kV/250 MHz P6150. The first reference pulse which was used as calibration pulse is shown in Fig. 4, with 50 ns rise time and around 1 kV magnitude. Characteristic of pulse registered by P6150 probe. As seen in Fig. 5 LRD output appropriately follow the reference pulse. 1200 Amplitude Fig. 6. Comparison of Marx Generator Pulse measurements by 15HF-HVP and LRD (CH2 and CH4 represent the reference and LRD waveform, respectively) 1000 800 600 400 200 0 -200 -400 -600 -1 0 1 2 3 4 5 6 7 8 9 Time 10–7 Fig. 4. Calibration pulse acquired with P6150 probe Amplitude 0.1 0.08 0.06 Fig. 7. Frequency response of LRD acquired by ROHDE&SCHWARZ FSP SPECTRUM ANALYSER 0.04 0.02 Final calibration is extracting the frequency response of LRD. In this manner, a 50 Ω transmission line fixture was associated with LRD. As demonstrate in Fig. 7, the cut-off 3 dB frequency is around 10 MHz. As be seen in Fig. 7, the attenuation ratio of LDR is about 83 dB which leads to DR of LRD as follow: 0 -0.02 -0.04 -0.06 -1 0 1 2 3 4 5 6 7 Time Fig. 5. Registered waveforms by LRD 8 9 10–7 In addition, calibration of LRD was done by 16 kV MG pulse for HV performance certification. Registered waveforms are shown in Fig. 6 that certify the good performance of LRD. The division ratio of around 14000 is inferred. Final calibration is extracting the frequency response of LRD. In this manner, a 50 Ω transmission line fixture was associated with LRD. As demonstrate in Fig. 7, the cut-off 3 dB frequency is around 10 MHz. Final calibration is extracting the frequency response of LRD. In this manner, a 50 Ω transmission 10(93/ 20) 104.15 14125. 5. High voltage experimental verification To verify the LRD measurement, output pulse of a MG with 420 kV amplitude was measured and experimental results was obtained. To compare and verify the captured pulse shape, the test stand was modeled (Fig. 8) and simulated through commercial circuit analysis. Figures 9 and 10 display the simulation and experimental results, respectively. These figures confirm the good LRD performance. 294 Oral Session L1 1 R1 2 5.6u 2.5 1.5u 1 U1 2 V R_HVLD C1 R_Load 14.28n IC = 500k 5k 74 0 0 0 Fig. 8. Schematic model of system is drawn in Capture CIS KV Time Fig. 9. Simulation result of modeled system in Fig. 8 6. Conclusion The compact HV and fast tow stage liquid resistive divider is described in this paper. Also, the overall structure and analytic model of divider is presented. Calibration process was done with both Tektronix P6150 2 kV/250 MHz and Pintek HV-39pro 40 kV/220 MHz probes. Frequency response of divider was registered by the ROHDE&SCHWARZ FSP spectrum analyzer and 10 MHz bandwidth was obtained. Finally, reliable HV performance of divider was experienced through a 420 kV Marx generator and was certified with simulation result. References Fig. 10. Experimental MG pulse obtained from LRD [1] Z.Y. Lee, Rev. Sci. Instrum., 54, 1060–1062 (1983). [2] D.M. Barret, S.R. Byron, E.A. Crawford, D.H. Ford, W.D. Kimura, and M.J. Kusher, Rev. Sci. Instrum. 56, 2111–2115 (1985). [3] S.A. Boggs and N. Fujimoto, IEEE Trans. Elect. Insulation EI-19, 87–92 (1984). [4] A.I. Gerasimov, “Aqueous-Solution High-Voltage Resistors: Development, Study, and Application (Review),” 49, 1, pp. 1–26 (2006). 295