Factory Mutual - Dura-Line

advertisement

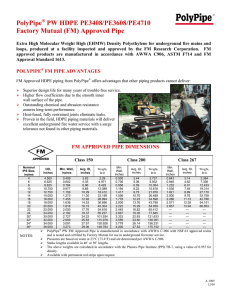

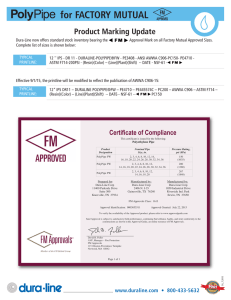

Factory Mutual Po ly Pip eF AC TO RY M UT UA L FM PE3408/PE4710 High Performance Pipe for Underground Fire Protection Systems FEATURES: • Heat-fused, fully restrained, leak proof joints • Maintains optimum flow rates due to resistance to corrosion & biological growth • Fatigue resistant • NSF-61 & NSF-14 certified • Meets ASTM D3350 cell classification PE445574C • Material grades PE3408/PE4710/PE100 per PPI TR-4 • AWWA C901 / ASTM D3035 & AWWA C906 / ASTM F714 SAMPLE PRINTLINE: 4'' IPS - DR 11 - DURALINE-POLYPIPE®FW - PE3408 - ANSI AWWA C906-PC150-PE4710-ASTM F714-200PSI (Resin Code)Y(##) - 5GC - (DDMMMYY) - NSF-61 - <FM> - (###) FT APPLICATION: Underground Fire Protection Systems SIZE RANGE: 2” – 36” (PC150, PC200) 2” – 20” (PC267) COLOR/STRIPE: Solid black, or with Stripe: red DL_5.2015 PolyPipe is manufactured with high performance resins engineered with outstanding resistance to Slow Crack Growth (SCG) and Rapid Crack Propagation (RCP). The fatigue resistance of these resins improves design life in water systems where cyclic pressure surges exist. Dura-Line is ISO 9001 certified and PolyPipe is qualified using exacting laboratory procedures and test methods, and a consistent uncompromised quest for design and manufacturing excellence. www.duraline.com • 800-433-5632 Factory Mutual PE3408/PE4710 – FACTORY MUTUAL (FM) PIPE FM APPROVED PIPE DIMENSIONS Nominal IPS Size Inches OD Inches Min. Wall, Inches 2 3 4 6 8 10 12 14 16 18 20 22 24 30 32 34 36 2.375 3.500 4.500 6.625 8.625 10.750 12.750 14.000 16.000 18.000 20.000 22.000 24.000 30.000 32.000 34.000 36.000 0.216 0.318 0.409 0.602 0.784 0.977 1.159 1.273 1.455 1.636 1.818 2.000 2.182 2.727 2.909 3.091 3.273 1.917 2.825 3.663 5.348 6.963 8.678 10.293 11.302 12.916 14.531 16.145 17.760 19.375 24.218 25.833 27.447 29.062 0.642 1.395 2.306 4.997 8.470 13.157 18.508 22.315 29.146 36.888 45.541 55.105 65.579 102.467 116.585 131.613 147.553 Min. Wall, inches 0.264 0.389 0.500 0.736 0.958 1.194 1.417 1.556 1.778 2.000 2.222 2.445 2.667 3.333 3.556 3.778 4.000 • PolyPipe® FM Approved Pipe is manufactured in accordance with AWWA C-901 & C-906 with NSF-61 approved resins and is tested and certified by Factory Mutual for use in underground firewater service. Class 200 (DR9) Avg. ID, Weight, inches lb/ft 1.816 2.676 3.440 5.064 6.593 8.218 9.747 10.702 12.231 13.760 15.289 16.818 18.347 22.933 24.462 25.991 27.520 0.766 0.642 2.751 5.963 10.106 15.618 22.085 26.628 34.779 44.017 54.342 65.754 78.253 122.270 139.116 157.049 176.069 Min. Wall, inches 0.339 0.500 0.643 0.946 1.232 1.536 1.821 2.000 2.286 2.571 2.857 ------------- Class 267 (DR7) Avg. ID, inches 1.656 2.440 3.137 4.619 6.013 7.494 8.889 9.760 11.154 12.549 13.943 ------------- Weight lb/ft 0.948 2.058 3.402 7.374 12.498 19.416 27.312 32.930 43.010 54.435 67.203 ------------- • Pressures are based on water at 23°C (73.4°F) and are determined per AWWA C-906. • Sticks lengths available in 40’ or 50’ lengths. • The above weights are calculated in accordance with the Plastics Pipe Institute (PPI) TR-7. DL_5.2015 NOTES: Class 150 (DR11) Avg. ID, Weight, Inches lb/ft www.duraline.com • 800-433-5632 Factory Mutual PE3408/PE4710 – FACTORY MUTUAL (FM) PIPE TYPICAL PHYSICAL PROPERTIES PROPERTY Density, Natural Density, Black Melt Index (190°C/2.16 kg) Flow Rate (190°C/21.6 kg) Tensile Strength @ Yield Ultimate Elongation Flexural Modulus 2% Secant Environmental Stress Crack Resistance (ESCR) PENT Brittleness Temperature Hardness, Shore D Vicat Softening Temperature Izod Impact Strength (Notched) Volume Resistivity Thermal Expansion Coefficient ASTM TEST METHOD *NOMINAL VALUES SI UNITS ENGLISH UNITS D1505 D1505 D1238 D1238 D638 D638 D790 0.949 gm/cc 0.960 gm/cc 0.08 gm/10 min. 7.5 gm/10 min. 24.8 MPa >800% 1,034 MPa ----3,600 psi >800% 150,000 psi F1473 D746 D2240 D1525 D256 D991 >500 hrs <-117°C 64 124° 0.42 KJ/m >1015 ohm-cm 2x10-4 cm/cm/°C >500 hrs. <-180°F 64 255°F 8 ft – lbf/in -8.0x10-5 in/in/°F CELL CLASSIFICATION: D3350 445574C PPI HYDROSTATIC DESIGN BASIS (HDB) D2837 11.0 MPa @ 23°C (As listed in PPI TR-4) 6.9 MPa @ 60°C PPI Hydrostatic Design Stress (HDS) 6.9 MPa @ 23°C (As established by the Hydrostatic Stress Board (HSB) of the Plastics Pipe Institute (PPI)) Grade PE47 1,600 psi @ 73.4°F 1,000 psi @ 140°F 1,000 psi @ 73.4°F DL_5.2015 *Nominal values are intended to be guides only, and not as specification limit. *Some of the data listed above was determined from compression molded test specimens: therefore, may deviate from pipe specimens www.duraline.com • 800-433-5632