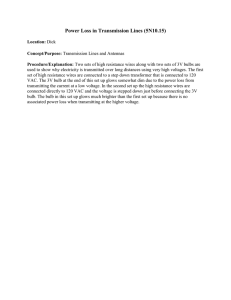

an investigation of the response of incandescent lamps

advertisement