Study of short-circuiting between adjacent joints under electric field

advertisement

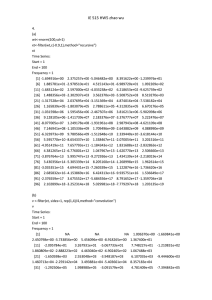

Microelectronics Reliability 42 (2002) 1945–1951 www.elsevier.com/locate/microrel Study of short-circuiting between adjacent joints under electric field effects in fine pitch anisotropic conductive adhesive interconnects Y.W. Chiu a a,* , Y.C. Chan a, S.M. Lui b Department of Electronic Engineering, City University of Hong Kong, 83 Tat Chee Avenue, Kowloon, Hong Kong b Varitronix Limited, 22 Chun Cheong Street, TKO Industrial Estate, Tseung Kwan O, Hong Kong Received 2 April 2002; received in revised form 14 May 2002 Abstract Anisotropic conductive adhesive film (ACF) has been extensively used in the liquid crystal display (LCD) industry for decades on chip-on-glass (COG) applications. It offers the advantages in terms of fine-pitch capability and more environment compatibility. One of the very important performance requirements of using ACF in fine pitch interconnection is not to create leakage of electric current between adjacent joints as it may lead to abnormal display segments/pixels of the LCD. In this work, the possibility of short-circuiting between adjacent joints in fine pitch ACF interconnections under the effects of electric field was investigated. Insulation resistance measurements of the selected adjacent joints against electric field strength 1 V/lm for a 24 h testing duration were discussed and analyzed. The results showed a strong dependence of curing degree of the ACFs on the chance of short-circuiting between adjacent joints under field effects. Ó 2002 Elsevier Science Ltd. All rights reserved. 1. Introduction Direct mounting of chip-on-glass (COG) substrate using anisotropic conductive adhesive film (ACF) is being widely used to satisfy the increasing demand for finer pitch interconnections in the liquid crystal display (LCD) industry. Although the extensively use of ACF for electrical conduction in LCD applications has been industrialized for many years, it is still under development and have stimulated significant interest. ACF interconnection is a rapid developing technology having the advantages of being lead-free, offers finer pitch capability, and lower cost with less processing steps at lower bonding temperatures. ACF is composite in nature, containing conductive particles in an insulating adhesive matrix. The principle of ACF joints in * Corresponding author. Fax: +852-2788-7579. E-mail addresses: eeywchiu@cityu.edu.hk (Y.W. Chiu), eeycchan@cityu.edu.hk (Y.C. Chan). COG assemblies is by interposing the adhesive so as to trap conductive particles between flip chip bumps and substrate tracks. Pressure and heat (thermo-compression) are applied simultaneously so that the conductive particles can make contact with both bumps and substrate tracks and to be electrically connected. A sufficient number of the conducting particles must be trapped during the bonding process to guarantee the electric contact with both conductor surfaces, but on the other hand, the particles loading should be kept low enough (ranging between 0.5 and 5 vol.% of conducting particles) [1], so that the material is not conductive between particles. Theoretically, the conductivity of ACF material is restricted to the z-direction only and with electrical isolation provided in the x–y plane. However, for very fine pitch applications, such as chips with less than 15 lm bump gap, it becomes more challenging to maintain in-plane electrical insulation. One of the important reliability issues concerning the use of ACF for fine pitch interconnections is the possibility of short-circuiting 0026-2714/02/$ - see front matter Ó 2002 Elsevier Science Ltd. All rights reserved. PII: S 0 0 2 6 - 2 7 1 4 ( 0 2 ) 0 0 0 9 7 - 5 1946 Y.W. Chiu et al. / Microelectronics Reliability 42 (2002) 1945–1951 between adjacent joints under applied electric field. Instability of joints is frequently found over time when voltage is applied, particularly at situations where cluster of conductive particles are trapped between bump gaps. A proposed failure mechanism––movement of conductive particles at a microscopic level in the presence of applied electric field––will be discussed. Previous studies have shown the movement of charged conducting particles under electric field in other applications such as viscous insulating liquid [2,3]. Modelling fluid flow for ACF during assembly [1,4] and study on the probability of bridging between bumps has also been studied earlier [1]. In this work, COG test vehicles using two different types of ACFs were prepared under various extent of curing reaction. The focus is on comparing the dependence of short-circuiting on the curing degree of the ACFs under the effects of electric field strength. Fourier transform infrared spectrophotometer (FT-IR) was employed to investigate the degree of cure as a function of time. The use of voltage source for insulation resistance measurement was performed to investigate the possibility of short-circuiting between joints. Table 1 Specifications of ACF 1 and ACF 2 Description ACF 1 ACF 2 Thickness (lm) Structure Conductive particle 30 Single layer Ni/Au plated resin Yes 30 Double layer Ni/Au plated resin No 51 125 51 111 Insulating coating on particle surface Particle size (lm) Tg (°C) glass substrate is 1.1 mm thick and the conductive trace pattern is sputter-deposited indium tin oxide, ITO (less than 1 lm thick). Two different types of thermosetting ACFs (ACF 1 and ACF 2), employing a random dispersion of conductive particles, were used in this study. They are commercially available and believed to have the capability for fine pitch interconnection. The detailed specifications given by the manufacturers are summarised in Table 1. 2.2. Bonding process 2. Experimental 2.1. Test chips, glass substrates and ACF materials In the design of test chip and glass substrate used in this study, five bumps with 10 or 15 lm bump gap are considered as a set of measuring unit. Two individual bumps are designed for insulation resistance test and three connecting bumps are intended for contact resistance test, as shown in Fig. 1. The test chips have a size of 3 11 mm2 , and there are 300 bumps around the periphery, with bump area of 50 70 lm2 . The bumps are electroplated with gold and the bump height is approximately 17 lm. A total of 24 sets of bumps with a choice of 10 or 15 lm bump gaps are available for insulation resistance measurement from a single chip. The All glass substrates were carefully cleaned using organic solvent, such as acetone, prior to use in order to remove any contaminants. ACFs were cut to the correct size to cover the bonding area automatically by the Toray SA2000 flip chip bonder and were preliminarily bonded to the glass substrate using low pressure (0.07 MPa) and low temperature (95 °C) for 2 s. After preliminary bonding, the separator was peeled off from the adhesive film immediately. Then the substrate pattern and the position of the chip bumps were aligned. Finally, the chip was bonded to the glass substrate by applying heat and pressure simultaneously for a specific duration. The bonding conditions are shown in Table 2. 2.3. Curing process Curing degree of the two ACFs was examined by using FT-IR spectroscopy. A Perkin–Elmer Spectrum One FT-IR Spectrometer, with a resolution of 4 cm1 , was used to get spectra from samples prepared at T ¼ 180 °C for five different reaction times (t ¼ 0, 5, 10, 15 and 20 s), see Fig. 2 for the typical spectra of ACF 1 and ACF 2 at t ¼ 0 s. Table 2 Bonding conditions for the two types of ACFs Description Fig. 1. Layout of a set of measuring unit on test chip. Bonding temperature (°C) Bonding pressure (MPa) Bonding time (s) ACF 1 180 0.18 5, 10, 20 ACF 2 Y.W. Chiu et al. / Microelectronics Reliability 42 (2002) 1945–1951 1947 Fig. 2. FT-IR spectra of the two different ACFs, (a) ACF 1 and (b) ACF 2, at bonding time t ¼ 0 s. The extent of curing reaction (a) at time t was calculated from the initial area of epoxy and reference peak, Aepoxy;0 and Aref;0 respectively, and their corresponding values at time t, Aepoxy;t and Aref;t , according to the following equation: a¼1 Aepoxy;t =Aref;t Aepoxy;0 =Aref;0 ð1Þ The peak at 915 cm1 was used to measure the amount of remaining epoxy group. The aromatic ring band at 1507 cm1 , which did not vary during cure, was considered as the internal reference [5–7]. Two enlarged views of the epoxy group absorption for ACF 1 and ACF 2, which comprises of peaks at 915 cm1 , are shown in Figs. 3 and 4 respectively. 2.4. Insulation resistance test Open-short test using a digital multi-meter was performed prior to insulation resistance test. Test joints were inspected and selected under an optical microscope. Only pairs of open-circuited adjacent joints with cluster of particles trapped in between were chosen to undergo the insulation resistance test (see Fig. 5). As the particles are expected to move at a microscopic level only, the said joints may give a higher chance of obtaining the predicted results. As measurement of insulation resistance is an indicator of short-circuiting, high resistance value (>108 X) indicates no current flow between adjacent joints while low resistance value (<104 X) indicates shorting is pre- sent. In this study, insulation resistance was measured between adjacent termini (bump gap, 10 or 15 lm) with the use of a Keithley 617 digital electrometer. A constant voltage was applied and resistance value was continuously measured and recorded during the aging process. Pre-selected samples cured for three different curing durations (t ¼ 5, 10 and 20 s) were tested under electric field strength of 1 V/lm for 24 h. 3. Results and discussion As thermo-compression is applied during bonding process, the ACF first softens and begins to flow and finally becomes hardened when the curing reaction has completed. The chemistry behind this is that the curing of ACF begins with the formation and linear growth of polymer chain in the epoxy resin that soon begins to branch, and then to cross-link. Finally, finishes as a three-dimensional, highly cross-linked chemical network [8]. As the reaction proceeds, transformation of epoxy resin from a rubbery state to a glassy state and becomes hardened [1]. Properties of an ACF depend on the degree of cross-linking from the curing reaction. In general, the cross-linking in the epoxy resin means the degree of curing [8] and its completeness greatly affects the rigidity of the ACF. From the results of FT-IR analysis, the continual decreasing of the epoxy band area at 915 cm1 over time shows that there is progressively consumption of epoxy group in cross-linking during the curing reaction. The lesser the epoxy band area remained, the more complete the cross-linking and 1948 Y.W. Chiu et al. / Microelectronics Reliability 42 (2002) 1945–1951 Fig. 3. Enlarged view of changes in epoxy absorption peaks for ACF 1, curing temperature at 180 °C for (a) t ¼ 0 s, (b) t ¼ 5 s, (c) t ¼ 10 s, (d) t ¼ 15 s and (e) t ¼ 20 s. Fig. 4. Enlarged view of changes in epoxy absorption peaks for ACF 2, curing temperature at 180 °C for (a) t ¼ 0 s, (b) t ¼ 5 s, (c) t ¼ 10 s, (d) t ¼ 15 s and (e) t ¼ 20 s. the stronger the chemical bonding, hence, the higher the rigidity of ACF. In other words, undercured ACF such as sample bonded at t ¼ 5 s (<50% cured) was observed to have a relatively large epoxy band area remained at 915 cm1 after thermo-compression, hence, a lower cross-link density and a weaker bonding force. Therefore, higher mobility of conductive particles may then be allowed, especially if an external electric field is applied. Conductive particles are randomly distributed over the adhesive film and the final positions reached by the particles are determined by the flow of the adhesive during the bonding process [4]. In the case when a cluster of particles are trapped between two adjacent bumps and exposed to electric field, the particles may be charged. If the applied electric field is high enough, the forces acting on the charged conductive particles can Y.W. Chiu et al. / Microelectronics Reliability 42 (2002) 1945–1951 1949 Fig. 5. Photograph of cluster of conductive particles trapped between a 15 lm bump gap: (a) top view and (b) cross-sectional view. become strong enough to overwhelm the holding forces of particles by the adhesive (such as viscous drag), the particles may start to move and pull adjacent particles closer to form conductive chains. Hence, causing undesirable shorting. A schematic representation of the particle movements under field effect is shown in Fig. 6. Based on the FT-IR spectra obtained, higher degree of curing will result in more reacted epoxy. The extent of curing reaction of the two ACFs can be calculated from Eq. (1) and is plotted as a function of cure time in Fig. 7 with the same curing temperature at 180 °C. The overall reaction rate (%) of ACF 1 is higher than that of ACF 2 under the same curing times (Fig. 7). When processed under the same bonding temperature, the extent of reaction increases with time. The rate of reaction is rapid at the beginning and slows down after t ¼ 10 s. A reaction rate of 80% or above is reached for both ACFs after curing for 10 s. From the results of the insulation resistance test, short-circuiting failures were found only from the samples cured at t ¼ 5 s. Examples of the changes in insulation resistance during the 24 h measurement for the failed (i.e. short-circuit) and passed (i.e. open-circuit) test samples were shown in Figs. 8–10. A dramatic drop of resistance from a high magnitude (ranged from GX to TX) to a low resistance (kX) was observed in the failed samples (see Fig. 8), whilst samples cured at both t ¼ 10 and 20 s (see Figs. 9 and 10 respectively) survived the test rather well. Although some of them might have experienced slight fluctuations of resistance over the test period, they still stayed at a high resistance level and no short-circuiting was found after the 24 h test. Fig. 11 shows the statistics of short-circuiting failures found after the insulation resistance test. At electric field of 1 V/lm, higher chance of shorting (25% failure) was found in both types of ACF at cure time t ¼ 5 s, where Fig. 6. Schematic representation of particle movements under electric field effects. 1950 Y.W. Chiu et al. / Microelectronics Reliability 42 (2002) 1945–1951 Fig. 10. Examples of failed samples cured at t ¼ 20 s after the insulation resistance test. Fig. 7. Plots of reaction rate (%) versus cure time (s) at cure temperature 180 °C. Fig. 11. Percentage failures of ACF 1 and ACF 2 against different degree of cure after applying electric field strength at 1 V/ lm for 24 h. Fig. 8. Examples of failed samples cured at t ¼ 5 s after the insulation resistance test. Fig. 9. Examples of failed samples cured at t ¼ 10 s after the insulation resistance test. their degrees of cure were below 50%. None was found from samples with cure time at both 10 and 20 s (above 80% cured) after 24 h. These results showed that the degree of curing of ACF plays an important role in determining the possibility of short-circuiting between adjacent joints under the field effects. Chances of failure were found higher in the undercured samples and a certain degree of curing (in this case, >80% cured) was needed for obtaining stable conductive adhesive joints without short-circuiting under the effects of electric field. One could see that the results of the two ACFs are very similar although the structure of conductive particles between the two is different, as particles in ACF 1 containing insulation layer at their outermost. There should be no electron flow between a perfect insulator and Au bump, even if they are in contact. Particles with insulation, therefore, should not be charged up and would not be affected by the field. However, failures were found and this may be explained by the wear-out Y.W. Chiu et al. / Microelectronics Reliability 42 (2002) 1945–1951 1951 under the field effects at a microscopic level and are seemed to be connected as conductive chains. Hence, the adjacent joints become short-circuited. All failures found in this study were long-term shorting; these results were well matched with our hypothesis, as the moved particles will remain in their final positions after withdrawal from the electric field and causes permanent failure. It can be concluded that curing degree of the ACFs will greatly influence the chance of short-circuiting between adjacent joints under electric field effects and there is no doubt that proper curing is very important for joint reliability. Acknowledgements Fig. 12. Schematic diagrams of different mode of frictions during bonding process: (a) particle-to-particle, (b) particleto-bump and (c) particle-to-substrate. mechanism of insulation layer during the bonding process. The insulation layer of the particles is very thin. It is only around 0.2–0.4 lm thick. When heat and pressure are applied during bonding, the adhesive resin is pressed out of the clearance between the Au bumps and the glass substrate with an accompanying flow of particles. Some of the particles are trapped in between the bonding electrodes while some of them are squeezed out of these narrow gaps to the bump gap. The frictions between particle-to-particle (Fig. 12a) or particle-tobump (Fig. 12b) or even particle-to-substrate (Fig. 12c) can easily damage or break the insulation layers, especially in the area where cluster of particles is present. Hence, the Au layer underneath is being exposed and the particles become conductive. Under applied electric field, short-circuiting problem may then happen. 4. Conclusions In this study, a higher chance (25%) of short-circuiting, under an applied electric field was found in the undercured ACF samples (<50% cured) after the insulation resistance test. However, none of the samples were found short-circuited in ACF samples with more than 80% cured. We believe that in the presence of electric field, the bonding force of the undercured ACFs may not be strong enough to hold the conductive particles in place. Particles may be allowed to move closer together The authors would like to acknowledge the financial support provided by the Hong Kong Research Grant Council fund for Co-operative Research Center on Conductive Adhesive Technology for High Density Electronic Packaging (project no. 8720003) and the Hong Kong SAR Government––Innovation and Technology Fund (ITF), University-Industry Collaboration Programme (project no. UIT/15). The authors also wish to thank Ms. Edwina Luk of City University of Hong Kong for proof reading. References [1] Liu J. Conductive adhesives for electronics packaging. UK: Electrochemical Publications Ltd; 1998. p. 99–116. [2] Choi C, Yatsuzuka K, Asano K. Dynamic motion of a conductive particle in viscous fluid under DC electric field. IEEE Trans Ind Appl 2001;37(3):785–91. [3] Atten P, Boissy C, Foulc JN. Attraction force between slightly conducting spheres immersed in a dielectric liquid. In: Conference Record of the ICDL Õ96, Italy, 15–19 July 1996. [4] Dudek R, Meinel S, Schubert A, Michel B, Dorfmuller L, Knoll PM, et al. Flow characterization and thermomechanical response of anisotropic conductive films. IEEE Trans Compon Pack Technol 1999;22(2):177–85. [5] Cherdoud-chihani A, Mouzali M, Abadie MJM. Study of crosslinking AMS/DGEBA system by FTIR. J Appl Polym Sci 1998;69:1167–78. [6] Mijovic J, Andjelic S. Monitoring of reactive processing by remote mid infra-red spectroscopy. Polymer 1996;37(8): 1295–303. [7] Meyer F, Sanz G, Eceiza A, Mondragon I. The effect of stoichiometry and thermal history during cure on structure and properties of epoxy networks. Polymer 1995;36(7): 1407–14. [8] May CA. Epoxy resins. New York: Marcel Dekker Inc; 1988.