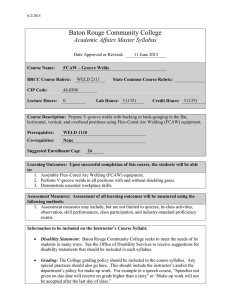

Mechanical Fastened vs. Welded Assembly C/S Mechanical Fastening

advertisement

Mechanically fastened extruded aluminum has been an Industry standard for many years. Construction Specialties, Inc., has engineered and furnished thousands mechanically fastened SunShade systems. We have furnished mechanically assembled products on thousands of jobs throughout the world. Technical Information Construction Specialties, Inc., has chosen mechanical fastening over welded construction for the following reasons: Configurations including adjacent blade overlap, make access to the weld areas extremely limited. In the shadow of the blades, welds appear dark. In direct sunlight welds appear as bright spots from all angels. Welding reduces outrigger strength. Will the outrigger fail? Do the calculations provided by the vendor allow for reduction? Actual installation of a major competitor’s Welded SunShade If a weld should crack during shipment, handling and/or erection, or if the SunShade is damaged, repair of welded louvers is extremely difficult. Welded areas are highly visible from the interior and exterior of the building. Features of Mechanical Fastened Sunshades ♦ Provides strength and durability ♦ Easily removed, straightened or replaced ♦ Make your building look more attractive C/S Mechanical Fastening Mechanical Fastened vs. Welded Assembly Mechanical Fastened vs. Welded Assembly Mechanically assembled extruded aluminum has been an industry standard as well as C/S standard since they were first marketed in the 1940’s. ♦ Configurations including adjacent blade overlap, make access to the weld areas extremely limited. It is very difficult to perform and inspect the tack welds to insure quality welds with full penetration through the joint. ♦ If a weld should crack during shipment, handling and/or erection, or if the louver is damaged, repair of welded louvers is extremely difficult. Adjacent welds must be broken to provide access and all broken welds must be cleaned off by chipping or machining. All finishes around the weld must be removed by sanding to prevent contamination of new welds. This causes substantial costs and delays. Mechanical Fastened Mechanical Fastened SunShade’s add a clean, smooth, esthetic appeal to a building. Welded SunShade’s are unattractive; Welds ♦ Inconsistent sizes & ♦ ♦ ♦ ♦ ♦ ♦ spacing Splatter Burn thru Can’t be ground smooth Discolor when anodized Reflect sunlight in all directions Show as shadows from below C/S Custom Grilles® Construction Specialties, Inc. USA Cranford, NJ 07016/49 Meeker Ave./Tel: (800) 631-7379/Fax: (908) 272-2920 Web Site: www.c-sgroup.com