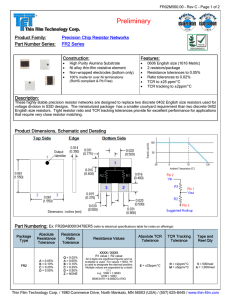

TaNFilm® Precision Molded DIP Resistor Network

advertisement

aNFilm® Precision Molded Resistors IP Resistor Network TaNFilm® Precision Molded Make Possible ® TaNFilm Precision Molded DIP Resistor Network 0 Series TaNFilm® ® Precision Molded TaNFilm Precision Molded os tolerances to ±0.05% DIP Resistor Network M900 Series olute TCR to ±25ppm/°C DIP Resistor Network DIP Resistor Network Ratios to tolerances to ±0.05% erior TCR tracking ±5ppm/°C M900 Series Ratios Absolute TCR to ±25ppm/°C •schematics tolerances to ±0.05% tom circuit M900 Series available M900 Series Superior TCR tracking to ±5ppm/°C • Absolute TCR to ±25ppm/°C • Ratios tolerances to ±0.05% Pb and 100% matte tin terminations available • Ratios tolerances to ±0.05% •• Superior TCR tracking to ±5ppm/°C Custom circuit schematics available Absolute TCR to ±25ppm/°C •• Absolute TCR to ±25ppm/°C Custom circuit schematics available • Superior to ±5ppm/°C Sn/PbTCR and tracking 100% matte tin terminations available Superior TCR tracking ••• Sn/Pb and 100% mattetotin±5ppm/°C terminations available ® Custom circuit schematics available s TaNFilm M900 series resistor networks are designed for • Custom circuit schematics available • Sn/Pb and 100% matte tin terminations available Pb-free parts comply with EU Directive 2011/65/EU (RoHS2) in applications requiring a high degree of reliability, Allstability, • Sn/Pb and 100% ® matte tin terminations available IRC’s TaNFilm M900 series resistor networks are designed for tolerance, excellent TCR tracking, noise. stability, The molded construction provides exce use applications requiring a high and degreelow ofare reliability, ® IRC’sinTaNFilm M900 series resistor networks designed for ® nsional stability for automatic insertion. Our continuous feed, high vacuumprovides sputtering process ins tight excellent TCRresistor and of low noise. The molded construction excellent IRC’sintolerance, TaNFilm M900 series are designed for use applications requiring a tracking, high networks degree reliability, stability, dimensional stability for automatic insertion. Our continuous feed, high vacuum sputtering process insures use intolerance, applications requiring a tracking, high degree stability, rm properties from network toTCR network. Precise state-of-the-art trimming enables us to easily tight excellent and of lowreliability, noise. The moldedlaser construction provides excellent uniform properties from network network.and Precise state-of-the-art laservacuum trimming enables us to easily zero tight tolerance, excellent TCR to tracking, low noise. The molded construction provides excellent dimensional stability for automatic insertion. Our continuous feed, high sputtering process insures e tightestin ratios. Passivated Tantalum Nitride resistor fifeed, lm ensures performance far superior to mil the tightest ratios. Passivated resistor film ensures far superior to insures military dimensional stability for automatic insertion. Our continuous high vacuum process uniform properties from network toTantalum network. Nitride Precise state-of-the-art laserperformance trimmingsputtering enables us to easily zero ifications uniform and provides excellent environmental protection. specifi and provides excellent environmental protection. properties fromPassivated network toTantalum network. Precise state-of-the-art laserperformance trimming enables us to easily zero in the cations tightest ratios. Nitride resistor film ensures far superior to military in the cations tightest and ratios. Passivated Tantalum Nitride protection. resistor film ensures performance far superior to military specifi provides excellent environmental The versatile of our excellent photo-etch process makes it possible to supply virtually any circuit configuration specifi cations nature and provides environmental protection. versatile needed naturetoof our photo-etch process makes it possible to anya modest circuit configura meet special customer requirements. Custom designs cansupply be easilyvirtually achieved The versatile nature of our photo-etch process makes it circuit possible to supply virtually any circuitwith configuration set up charge. Military available on allCustom units. ed to meet special customer requirements. circuit designs can be easily achieved The versatile nature ofscreening our photo-etch process makes possible to supply virtually any circuitwith confi needed to meet special customer requirements. Customit circuit designs can be easily achieved aguration modest with a mo needed to meet special customer requirements. Custom circuit designs can be easily achieved with a modest p charge.setMilitary screening available on on allallunits. up charge. Military screening available units. set up charge. Military screening available on all units. Electrical Data Electrical Data Resistance Data ectricalElectrical Data Schematic Range ematic Absolute Resistance Tolerance Absolute (Ω) Schematic Resistance Range Absolute Tolerance Resistance Schematic Range 10 (Ω) - 49.9 F, G, J Tolerance Absolute (Ω) Range (Ω) A 10 -A49.9 A A 50.0 - 199 200 - 999 B 1.0K -B400K B 50 - 149 B Optional Ratio Optional Tolerance Optional Ratio Optional Ratio Tolerance F, G Tolerance Ratio 10Tolerance - -49.9 F, 50.0 199 F, G, G, JJ D,F,F,GG 10 - 49.9 F, G, J F, G Tolerance 50.0 199 F, G, J J 200 -- 999 B, D, F, G, A, D, B, F, D, G F, G 50.0 - 199 D, F, G F, G, J F, G, J F, G 200 -- 400K 999 B, D, D, F, F, G, G, JJ A, B, B, D, D, F, F, G G 1.0K B, A, 200 - 999 B, D, F, G, J A, B, D, F, G F, G, J B, D,A,F, G 1.0K 400K 50 -- 149 B, D, D, F, F, G, G, JJ B,B,D,D,F,F,GG 1.0K - 400K B, D, F, G, J A, B, D, F, G 50 --149 B, D, D, F, F, G, G, JJ B, D, D, F, F, G 150 499 B, D, F, G,B, F,F,GG 50B, - 149 B,JD, F, G, J A, B, D, B, D, G 150 499 B, D, F, G, J B, D, F, G 500 - 999 B, D, F, G, J B, D, F, G 150 - 499 B, D, F, G B, D, F, G,B,JD, F, G, J A, B, D, F, G 500 -- 200K 999 B, D, D, F, F, G, G, JJ B, D, D, F, F, G G 1.0K B, B, 500 - 999 B, D, F, G, J B, D, F, G D, F, G,B,JD, F, G, J B, D,B,F,D,G 1.0KB, - 200K F, G 1.0K - 200K B, D, F, G, J B, D, F, G 150 - 499 B, D, F, G,cation J B, D, F, G Package Specifi Data Package Specifi cation Data 500 - 999 B, D, F,Power G,cation J (W) Voltage B, D, F,Rating G Package Specifi Data Package Schematic Package Power16-pin (W) Voltage _____ Rating Schematic Package Rating 1.0K - 200K 8-pin B, D,14-pin F,Power G, J (W) Voltage B, D, F, notGto √ PxR Schematic A 0.8 1.4 1.6 _____ 8-pin 14-pin 16-pin 100V _____ 8-pin 14-pin 16-pin √exceed PxR not to B 0.7 1.3 1.5 A 0.8 1.4 1.6 PxR not to √exceed 100V A 0.8 1.4 1.6 Custom circuits testing available. values below 200Ω. 100V B and special 0.7 1.3 *Contact 1.5factory forexceed B 0.7 1.3 1.5 Absolute TCR (ppm/°C) Absolute TCR Absolute TCR (ppm/°C) ±50; ±100; ±300 TCR (ppm/°C) Absolute ±50; ±100; ±300 (ppm/°C) ±25; ±50; ±100; ±300 ±50; ±100; ±300 ±25; ±25; ±50; ±50; ±100; ±100; ±300 ±300 ±25; ±50; ±100; ±300 ±50; ±100; ±300 ±25; ±50; ±50; ±100; ±100; ±300 ±300 ±25; ±25; ±50; ±100; ±300 ±25; ±50; ±100; ±300 ±25; ±50; ±100; ±300; ±100±300 ±25; ±50; ±100; ±300 ±300; ±100 ±300; ±100; ±50 ±25; ±50; ±100; ±300 ±300; ±100 ±300; ±25; ±50;±100; ±100;±50 ±300 ±300; ±100; ±50 ±25; ±50; ±100; ±300 ±25; ±50; ±50; ±100; ±100; ±300 ±300 ±25; ±25; ±50; ±100; ±300 ±300; ±100 ±25; ±50; ±100; ±300 ±25; ±50; ±100; ±300 ±20 ±10 ±20 ±10 ±5 ±10 ±5 ±5 ±5 ±5 ±50 ±5 ±50 ±20 ±50 ±20 ±5 ±20 ±5 ±5 ±5 ±5 ±5 ±300; ±100; ±50 Temperature ±25; ±50; ±100; ±300 Substrate Range Temperature Substrate Temperature Range Substrate ±25; ±50; ±100; ±300 Range -55°C to +150°C 99.5% Alumina -55°C to +150°C 99.5% Alumina -55°C to +150°C 99.5% Alumina ckage Specification Data ematic Element Tracking TCR Power Element (ppm/°C) Tracking TCR (mW) Element Power Tracking TCR (ppm/°C) Power ±20 Tracking (mW) (ppm/°C) TCR (mW) (ppm/°C) 200 ±20 Element Power (mW) 200 200 ±10 200 ±5 ±5 100 100 100 ±50 ±20 Lead Finish ±5 Options Lead Finish Lead Finish Options ±5 Options Sn/Pb solder plate 100% matte tin plate Sn/Pb solder plate Sn/Pbmatte solder 100% tinplate plate 100% matte tin plate 100 Noise Noise Noise <-30dB <-30dB <-30dB Custom circuits and special testing available. *Contact factory for values below 200Ω. Custom circuits General Noteand special testing available. *Contact factory for values below 200Ω. IRC reserves the right to make changes in product specification without notice or liability. General Note All information is subject to IRC’s own data and is considered accurate at time of going to print. General Note Temperature Range TT Electronics reserves the right to make changes in product specification without notice or liability. IRC reservesNote the right to make changes in product specification without notice or liability. General © IRC Advanced Film South Staples Street • Corpus Christi Texas 78411 USAof going to print. Allinformation information is subject toDivision TTdata Electronics’ own data and considered at time All is subject IRC’s own and•is4222 considered accurate atis time of toaccurate print. IRC reserves the right to to make changes in product specifi cation without notice or going liability. Telephone: 361is992 7900to• Facsimile: • Website:accurate www.irctt.com All information subject IRC’s own 361 data992 and3377 is considered at time of going to print. © IRC Advanced Film Division • 4222 South Staples Street • Corpus Christi Texas 78411 USA © TT Electronics Telephone: 361 992 7900 Film •plc Facsimile: 361 992 3377 www.irctt.com © IRC Advanced Division • 4222• Website: South Staples Street • Corpus Christi Texas 78411 USA Telephone: 361 992 7900 • Facsimile: 361 992 3377 • Website: www.irctt.com Package Power (W) 8-pin 14-pin 16-pin Voltage Rating _____ √ PxR not to Substrate subsidiary of LeadTTAelectronics Finish plc A subsidiary M900 Series Issue January 2009 Sheet 1 ofof3 www.ttelectronicsresistors.com Options TTAelectronics subsidiaryplc of TT electronics M900 Series Issue January 2009 Sheet 1 ofplc3 M900 Series Issue January 2009 Sheet 1 of 3 11.14 Sn/Pb solder plate No TaNFilm Precision Molded DIPSeriesResistor Network M900 ® Molded TaNFilm® Precision DIP Resistor Networks Make Possible Environmental Data MIL-PRF-83401 Limits (Delta R%) TaNFilm Test Data (Delta R%) Test Per MIL-PRF-83401 M K H Max Typical Thermal Shock And Power Conditioning 0.7 0.7 0.5 0.10 0.02 Low Temperature Operation 0.5 0.25 0.1 0.1 0.02 Short-term Overload 0.5 0.25 0.1 0.05 0.02 Terminal Strength 0.25 0.25 0.25 0.1 0.02 Resistance To Solder Heat 0.25 0.25 0.1 0.1 0.02 Moisture Resistance 0.5 0.5 0.4 0.1 0.02 Shock 0.25 0.25 0.25 0.1 0.02 Vibration 0.25 0.25 0.25 0.1 0.02 Life 2.0 0.5 0.5 0.1 0.02 High Temperature Exposure 1.0 0.5 0.2 0.1 0.02 Low Temperature Storage 0.5 0.25 0.1 0.1 0.02 25°C Double Load 2.0 0.5 0.5 0.05 0.02 Schematic Data N N R1 R1 1 2 3 1 Schematic A Isolated Note: N = number of pads © IRC Advanced Film Division • 4222 South Staples Street • Corpus Christi Texas 78411 USA Telephone: 361 992 7900 • Facsimile: 361 992 3377 • Website: www.irctt.com 2 3 Schematic B Bussed (highest number pin is common) M900 Series Issue January 2009 Sheet 2 of 3 General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. www.ttelectronicsresistors.com © TT Electronics plc 11.14 TaNFilm Precision Molded DIP Resistor Network M900 Series ® TaNFilm® Precision Molded DIP Resistor Networks Make Possible Physical Data A Max 8 Pin .465 14 Pin .765 16 Pin .865 .310 ±.010 A +.005 .260 -.000 .035 ±.010 +.005 .180 -.007 .331 Max +.015 .135 -.010 .010 ±.002 .065 .080 ±.005 .100 ±.010 Typ Nonaccumulative +.005 -.003 .320 .360 .019 ±.002 Ordering Data Sample Part No. DPB - M989 - 02 - 1002 - F B Style M954, M954LF = 8-pin DIP, schematic B M959, M959LF = 8-pin DIP, schematic A M987, M987LF = 14-pin DIP, schematic B M989, M989LF = 14-pin DIP, schematic A M998, M998LF = 16-pin DIP, schematic B M999, M999LF = 16-pin DIP, schematic A Note: LF indicates 100% matte tin terminations TCR Code 01 = ±100ppm/°C; 02 = ±50ppm/°C; 03 = ±25ppm/°C Resistance 4-Digit resistance code Ex: 1002 = 10KΩ; 50R1 = 50.1Ω Absolute Tolerance Code G = ±2%; F = ±1%; D = ±0.5%; C = ±0.25%; B = ±0.1% Optional Ratio Tolerance to R1 G = ±2%; F = ±1%; D = ±0.5%; C = ±0.25%; B = ±0.1%; A = ±0.05% © IRC Advanced Film Division • 4222 South Staples Street • Corpus Christi Texas 78411 USA Telephone: 361 992 7900 • Facsimile: 361 992 3377 • Website: www.irctt.com M900 Series Issue January 2009 Sheet 2 of 3 General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. www.ttelectronicsresistors.com © TT Electronics plc 11.14