Inspection checklist

advertisement

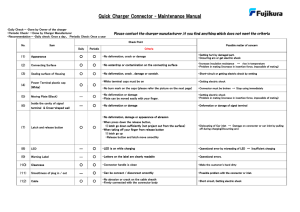

JAHL-40147 Attachment 2 Quick charge cable inspection details < JAE connector > ・ Daily inspections: Equipment supervisors/managers (for example, the manager of a gas station), subcontractors, etc. ・Regular inspections: Charger distributors (charger manufacturers), subcontractors, etc. ・Recommended inspection frequency: Once a day for daily inspection, once a year for regular inspection Inspection requirement No. Inspection item Daily 1 Connector appearance 2 Connector bonding surface ○ ○ Periodic ○ ○ Judgment criteria ・No deformation, cracks, damage, etc., can be detected through visual inspection. Reference diagram - ・No water drops or foreign objects are attached to the connector bonding surface. ① 3 Housing sealing surface 4 Power terminal 5 Power terminal resin cap 6 Signal terminal ○ ○ ○ ○ ・Injury caused by damaged parts. ・Arc generation or electric shock due to damaged insulation. ・Increase in resistance of terminal contacts due to attached foreign object. → Temperature increase. ・Increase in connection force required or connection impossible due to the foreign object. ○ ・No deformation, cracks, damage, scratches, etc., can be detected through visual inspection. ・Short circuit or electric shock due to ingress of water. ○ ・No deformation, scratches, etc., can be detected through visual inspection. ・Increase in resistance due to terminal contact failure → Temperature increase. ・Increase in connection force required/connection impossible. ○ ○ ② ・All resin caps are attached. ・Electric shock from touching terminals. ・No deformation, scratches etc., can be detected through visual inspection. ・Increase in resistance due to terminal contact failure → Cannot charge. ・Increase in connection force required/connection impossible. ③ ○ ○ ・No deformation, damage, etc., can be detected through visual inspection. ○ ○ ・No deformation, damage, abrasions, etc., can be detected through visual inspection. ・Latch moves normally when it is pressed. ④ ○ ○ ・No exposed internal buffer materials or insulation layers due to abrasions or cracks on the sheath surface. ・No loose connectors. - ・Short circuit or electric shock due to exposed copper conductor. 10 Connector insertion/removal - ○ ・Smooth insertion and removal into/from the inlet . - ・Failure due to defective connector (inlet). 11 Electromagnetic lock - ○ ・Locks when charging and the connector cannot be removed. 7 Cross-shaped walls in signal terminal cavities Possible effect of defect 8 Latch 9 Cable ・Insufficient protection for signal terminals. → Signal terminal deformation. ・Incomplete hook lock to inlet. → Damage on connector or inlet due to loose connection during charging (arc generation) . ・Damage on the connector or inlet due to loose connection during charging (arc generation) . ⑤ ・Incorrect operation due to loss of “Charging” display. → Incomplete charging. 12 LED lamp - ○ ・LED turns on during charging. 13 Cleaning ○ ○ ・Areas where hands touch must be clean. - ・Feeling of discomfort by charge operator. 14 Loose screw ○ ○ ・No screw is loose or missing. - ・Connector broken apart due to missing screw. → Failure. ⑥ ・Connector cannot be removed. ⑦ ・Occurrence of failure due to misunderstanding. 15 Release button ○ ○ ・No deformation, cracks, damage, etc., can be detected through visual inspection. ・Latch moves normally according to the movement of the release button when it is pressed. ・Latch returns when the release button is released. 16 Caution Label ○ ○ ・The label does not peel off, and each characters donot disappear. JAHL-40147 Attachment 3 Inspection Method and Details ① No. 2 connector bonding surface/No. 3 housing sealing surface ・Bonding surface: Check the condition of the connector bonding area (shaded area). ・Sealing surface: Check the inner walls of each individual room (dotted line area shown above). ② No. 4 power terminals/No. 5 resin caps Power terminals: 2 ・Resin cap attached to the tip of power terminal (shaded area parts) ③ No. 6 signal terminals/No. 7 cross-shaped walls in signal terminal cavities Signal terminals: 3 Cross-shaped walls: 2 locations Signal terminals: 4 ・Cross-shaped walls in signal terminal cavities (dotted line area shown above) JAHL-40147 Attachment 3 ④No. 8 latch ・Slightly press the latch inward towards the case and check if it moves smoothly. ・Also, check if it returns smoothly when the latch is released. When the latch is pressed Latch ⑤ No. 11 electromagnetic lock/No. 12 LED lamp Press ・To check the operation status of the electromagnetic lock, slightly press the release button with your finger while charging a vehicle. ⇒ Stop using the product and request repair if the button is pressed but “UNLOCK” remains displayed on the incomplete connection indicator or charging stops. Incomplete connection indicator Release button Stop using the product if “UNLOCK” appears during charging. Red LED is on (Charging) ⑥No. 15 release button Press ・Press the release button with your finger to check if the button moves smoothly. ・Press the release button with your finger to check if the latch moves inward smoothly. ・Check if the release button and latch return smoothly when the release button is released. Latch Release button JAHL-40147 Attachment 3 ⑦No. 16 Caution Label ・The label does not peel off, and each characters donot disappear.