Ohio EPA Laboratory Manual for Microbiological

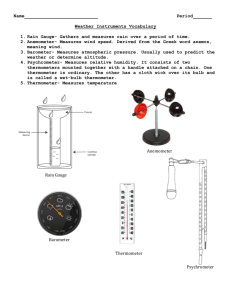

advertisement