Complete Lab Safety Manual - Environmental Health and Safety

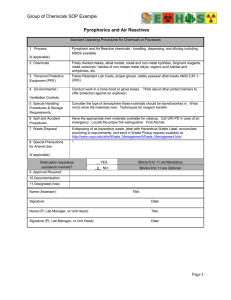

advertisement