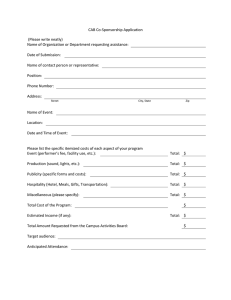

MT500B AP IV

PRODUCT INFORMATION GUIDE

William Zak

Sales Engineer / Marketing Specialist

February 2004

MT500B

AUTOPOWER IV

TABLE OF CONTENTS

CHALLENGER ® MT500B SERIES

INTRODUCTION.................................................................................

GENERAL.........................................................................................................1

DESCRIPTION OF PRODUCT .................................................................... 2-3

MARKET ..........................................................................................................4

SPECIFICATIONS ..............................................................................

MT525B .................................................................................................... 5 - 15

MT535B .................................................................................................. 16 - 26

MT545B .................................................................................................. 27 - 37

MT555B ..................................................................................................38 – 48

MT565B .................................................................................................. 49 - 59

FEATURES AND BENEFITS .............................................................

Overall..................................................................................................... 60 - 61

Engine..................................................................................................... 62 - 65

Transmission........................................................................................... 66 - 69

Differential, Brakes, & Final Drive ........................................................... 70 - 72

Axle and Wheels .............................................................................................73

Front Axle................................................................................................ 74 - 77

Tires ........................................................................................................ 78 - 79

Power Take Off ....................................................................................... 80 - 81

Hydraulics ............................................................................................... 82 - 91

Operator Environment........................................................................... 92 - 103

Serviceability.......................................................................................104 – 107

COMPETITIVE COMPARISONS........................................................................

MT525B vs.......................................................................................... 108 - 111

MT535B vs.......................................................................................... 112 - 115

MT545B vs.......................................................................................... 116 - 119

MT555B vs..........................................................................................120 – 123

MT565B vs.......................................................................................... 124 - 127

I

INTRODUCTION

CHALLENGER

®

MT SERIES

GENERAL

The new Challenger® tractors have been developed to meet the needs of today’s progressive growers. Advanced styling combined with high performance features provide improved versatility and outstanding reliability.

While designing these new features, Challenger® engineers were dedicated to providing a tractor that has proven durability and exceptional operator comfort and convenience. Advanced engine and power train technology define the 60 to 225 horsepower Challenger® tractors. This allows better compatibility with a wide variety of equipment and will make owning an Challenger® tractor more appealing to owners and operators across a larger spectrum of needs and demands.

1

INTRODUCTION

CHALLENGER

®

MT SERIES

DESCRIPTION OF PRODUCT

The CHALLENGER ® Series tractor family is comprised of the following models:

The Challenger MT400B Series tractors feature amenities that the customers have asked for.

Caterpillar engines provide durable and reliable power for tough jobs. A 16X16 transmission provide the customer with easier operation and lower maintenance costs. The cabs have been designed with efficient air conditioning operation and control. Easy to remove engine side panels still make tractor service convenient.

The Challenger MT500B Series tractors have been developed to meet a wider variety of demands. More chassis designs are offered in a broader horsepower range. Five cab tractors will meet the demands of customers needing a highly flexible loader tractor or small to mid size row crop tractor. The 500B tractors will meet the needs of today’s farmers, landscapers or municipalities.

2

INTRODUCTION

CHALLENGER

®

MT SERIES

Four models make up the Challenger MT 600 Series of tractors. These are heavy duty row crop tractors that bring measurable meaning to field productivity and operator comfort. All four models are powered by SISU turbocharged engines. All four models feature an electronic controlled Powershift transmission. And all four tractors have convenient operator controls found in a comfortable cab.

3

INTRODUCTION

CHALLENGER

®

MT SERIES

MARKET

The North American tractor market continues to expand and develop into many different areas. With a wide variety of different attachments, these machines are ideally suited for customers ranging from weekenders to municipalities and farmers.

Some potential customers include:

• Corporate Farmers

• Specialty Farmers

• Traditional Farmers

• Hobby Farmers

• Government

• Municipalities

• Construction

4

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

GENERAL

Make ................................................................................................................... Challenger

Model ......................................................................................................................... MT525B

Class ......................................................................................................... Mid Size Row Crop

Type Isolation-Mounted Cab, 2WD or 4WD

PTO AND DRAWBAR PERFORMANCE

PTO hp @ Rated Engine rpm hp (kW) ........................................................95 (70.8) @ 2,200

Fuel Consumption @ Rated Engine rpm gph (lph) ..............................................................

Fuel Consumption @ Rated Engine rpm hp h/gal (kW.h/l) ..................................................

PTO hp @ Standard PTO rpm hp (kW)....................................................................................

Fuel Consumption @ Standard PTO rpm gph (lph) .............................................................

Fuel Consumption @ Standard PTO rpm hp h/gal (kW.h/l) .................................................

Maximum Drawbar hp (Unballasted) (PFA) hp (kW) ................................................................

Fuel Consumption @ Maximum DBhp gph (lph)..................................................................

Fuel Consumption @ Maximum DBhp hp·h/gal (kW.h/l)......................................................

Maximum PTO Torque @ Rated Speed lbf-ft (N·m).................................................................

Maximum PTO Torque @ rpm lbf-ft (N·m) ...............................................................................

PTO Torque Rise .....................................................................................................................

Official Test ....................................................................................... Manufacturer’s Estimate

ENGINE GENERAL

Model ............................................................................................................. Caterpillar 3056

Type .......................................................................... In-Line, 4-Cycle, Direct Injection, Diesel

Cylinder Head Design .................................................One Piece, Cast Iron, Overhead Valve

Number of Cylinders...............................................................................................................6

Bore in (mm)............................................................................................................ 3.94 (100)

Stroke in (mm)......................................................................................................... 5.00 (127)

Displacement CID (L) .......................................................................................... 365 (5.985L)

Compression Ratio........................................................................................................17.5: 1

Aspiration ..........................................................................Turbocharged - Charge Air Cooled

Starting Aid........................................................................................................... Thermostart

Block Heater.....................................................................750 Watt Coolant Heater (Optional)

Challenger ® has a company policy of continuous improvement; therefore,

Specifications are subject to change without notice.

5

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

ENGINE SYSTEMS

Cooling System

Type ........................................................................ Pressurized Liquid, Forced Circulation

Temperature Control ..........................................................................................Thermostat

Fan

Number of Blades......................................................................................................9

Diameter in (mm)........................................................................................ 21.6 (550)

Drive ............................................................................................................... Viscous

Air Intake System

Intake Location................................................................................................. Top of Hood

Air Cleaner

Type.............................................................................................Dry Donaldson FPG10

Number of Elements ........................................................ 2: 1 Primary and 1 Secondary

Material..................................................................................................... Pleated Paper

Restriction Indicator ...................................................................................Warning Light

Exhaust System

Type ................................................................................ Vertical, at Right, Front Cab Post

Muffler Location .............................................Integral w/External Elbow and Vertical Stack

Fuel Injection System

Type of Injection......................................................................................................... Direct

Injection Pump ...........................................................................................................Bosch

Type....................................................................................................... Electronic VP30

Drive ............................................................................................................Timing Gear

Injectors ......................................................................................... Bosch DSLA Multi-Hole

Governor

Type.................................................................................................................Electronic

Governed Speed Range rpm .........................................................................800 – 2350

Rated Engine rpm ........................................................................................................2200

Lubrication System

Type ................................................................ Full Pressure, Full Flow w/Bypass & Cooler

Filter .......................................................................................................... Spin-on Canister

Number of Filters ...............................................................................................................2

Pump Type...................................................................................................................Gear

Pump Drive ........................................................................................................ Crankshaft

6

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

ENGINE SYSTEMS (Cont.)

Crankcase, Cylinder Block, & Cylinder Head

Cylinder Block .................................................... Cast Iron, Six-Cylinder Parent Bore Block

Cylinder Head .............................................................. One-Piece, Cast, Overhead Valves

Pistons ...........................................................Cast Aluminum Alloy, Controlled Expansion,

Top Ring Insert, Re-Entrant Bowl

Crankshaft............................................................................................... Cold Drop Forged

Number of Main Bearings ..................................................................................................7

POWER TRAIN

Clutch

AutoPower IV ® Transmission Tractors

Type.........................................................................................................Wet, Multi-Disc

Number of Discs ............................................................................................................5

Main Disc Diameter in (mm) ................................................................................ 9 (230)

Control ................................................. Foot Pedal and PowerControl Modulating Valve

Actuation...........................................................................................................Hydraulic

Free-Play Adjustment ................................................................................Self-Adjusting

Type.......................................................Inching Pedal, Electronic Transmission Control

Transmission

AutoPower IV ®

Type....................................................Mechanical, Transmission w/4-Speed Powershift

PowerShuttle............................................................................ Left Side of Steering Wheel

Speeds ..................................................................................... 32 Forward, 32 Reverse

Gears................................................................................ 4 Synchronized, 4 Powershift

Ranges ................................................................ 2 Synchromesh and Dual Wet Clutch,

Electronic Controlled Hydraulic Shuttle

Creeper...................................................................................... Optional, 4:1 Reduction

Differential and Final Drive

Type ........................................................ Primary Reduction - Spiral Hypoid Ring & Pinion

Secondary Reduction – Planetary Gear Set

Differential Lock

Type.......................................................................... Sliding Collar, Engage On-The-Go

Engagement ........................................................................................ Electro-Hydraulic

Final Drive............................................................................................... Inboard Planetary

7

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Differential and Final Drive (Cont.)

Brakes

Rear..................................................................................................... Inboard Wet Disc

Actuation...........................................................................................................Hydraulic

Parking Brake .....................................Hand Operated Lever, Multi-Disc, Acts on Pinion

AutoPower IV® Transmission

Travel Speeds @ Rated Engine rpm (18.4R38 REAR TIRES)

1 2 3 4 mph (kph) mph (kph) mph (kph) mph (kph)

Trans.

Speed

A

Forward B

Turtle C

D

A

Forward B

Rabbit C

D

1.34 (2.17)

1.57 (2.54)

1.85 (2.99)

2.17 (3.50)

5.04 (8.12)

5.90 (9.51)

6.97 (11.22)

8.15 (13.13)

2.03 (3.27)

2.37 (3.83)

2.52 (4.52)

3.29 (5.29)

7.62 (12.27)

8.92 (14.36)

10.55 (16.95)

12.32 (19.84)

3.01 (4.85)

3.52 (5.67)

4.16 (6.70)

4.87 (7.84)

11.28 (18.16)

13.21 (21.26)

15.59 (25.09)

18.24 (29.37)

4.67 (7.52)

5.46 (8.80)

6.45 (10.39)

7.55 (12.16)

17.51 (28.18)

20.49 (32.98)

24.10 (38.93)

A

Reverse B

Turtle C

D

A

Reverse B

Rabbit C

D

1.34 (2.17)

1.57 (2.54)

1.85 (2.99)

2.17 (3.50)

5.04 (8.12)

5.90 (9.51)

6.97 (11.22)

8.15 (13.13)

2.03 (3.27)

2.37 (3.83)

2.52 (4.52)

3.29 (5.29)

7.62 (12.27)

8.92 (14.36)

10.55 (16.95)

12.32 (19.84)

3.01 (4.85)

3.52 (5.67)

4.16 (6.70)

4.87 (7.84)

11.28 (18.16)

13.21 (21.26)

15.59 (25.09)

18.24 (29.37)

Standard Speed x .25 = Creeper Speed (Turtle Range Only)

4.67 (7.52)

5.46 (8.80)

6.45 (10.39)

7.55 (12.16)

17.51 (28.18)

20.49 (32.98)

24.10 (38.93)

8

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Rear Axle

Type ..........................................................................................................................Flange

Tread Settings in (mm)

Welded Steel .......................................................................... 66.9 (1700) – 73.5 (1868)

Manual Adjust Steel................................................................ 56.4 (1432) – 76.9 (1954)

Cast PAVT ............................................................................. 54.4 (1382) – 88.1 (2238)

Maximum Permissible Rear Tire Diameter in (mm).............................................. 72 (1834)

Maximum Permissible Axle Static Load Limit lb (kg)..................................... 12,345 (5600)

2WD Adjustable Front Axle

Type ....................................................................................Telescopic, Box-In-Box Design

Steering Angle degrees....................................................................................................55

Tread Setting

Adjustment Increments in (mm) ...................................................................... 3.94 (100)

Tread Adjustment Range (10:00 x 16 Tire)

Wheel Turned In in (mm).................................................... 64.1 (1629) – 79.9 (2029)

Wheel Turned Out in (mm) ................................................. 67.2 (1707) – 83.0 (2107)

Wheel Turned In Wide Row Crop in (mm).......................... 73.2 (1861) – 92.9 (2361)

Wheel Turned Out Wide Row Crop in (mm) ....................... 76.4 (1939) – 96.0 (2439)

Maximum Permissible Axle Static Load Limit lb (kg)....................................... 4,652 (2110)

4WD Front Axle

Type ............................................................Center Pivot, Mechanical Drive, Carraro 20.19

Standard ....................................................................................................Fixed Front Axle

Optional.............................................................................. Hydraulic Suspeded Front Axle

Steering Angle degrees....................................................................................................55

Drive.............................................................................................. Centerline Splined Shaft

Drive Ratio ..................................................................................................................1.337

Method of Engagement....................................... Electro-Hydraulic, Wet, Multi-Disc Clutch

Differential Lock

Type............................................................................................................Sliding Collar

Method of Engagement ............................Electro-Hydraulic, Simultaneous w/Rear Axle

Tread Settings in (mm)................................................................ 61.7 (1567) – 80.8 (2053)

Maximum Permissible Axle Static Load Limit lb (kg)....................................... 7,054 (3200)

9

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Power Take-Off

Type .................................................................................................................Independent

Speeds rpm...........................................................................................................540/1000

Optional ................................................................................................................Economy

Control .........................................................................................Electro-Hydraulic Control

Clutch...........................................................................................................Wet, Multi-Disc

Clutch Disc Diameter in (mm) ............................................................................. 5.31 (135)

Shaft Configuration .................................................................................... Interchangeable

540 rpm in (mm) .............................................................................. 1.375 (35), 6 Spline

1000 rpm in (mm) .......................................................................... 1.375 (35), 21 Spline

Engine/PTO Speed Ratio

540 rpm ....................................................................................540 @ 1980 Engine rpm

1000 rpm ................................................................................1000 @ 2000 Engine rpm

Economy 540/1000..................................................................... 1533/1548 Engine rpm

HYDRAULICS AND HITCH

Closed Center System

Type .............................................................Closed-Center, Pressure, Flow Compensated

Drive....................................................................................................................PTO Shaft

Flow gpm (lpm) (2200 erpm)............................................................................... 29.0 (110)

Pressure psi (bar) .............................................................................................. 2900 (200)

Remote Valves standard (optional)........................................................................... 2 (3,4)

Dual Flow System (Load Sensing)

Type .....................................................................................................................Dual Flow

Drive....................................................................................................................PTO Shaft

Flow gpm (lpm) (2200 erpm)............................................................................... 26.4 (110)

Pressure psi (bar) .............................................................................................. 2900 (200)

Remote Valves standard (optional)........................................................................... 2 (3,4)

Filters

Number ..............................................................................................................................2

Type ............................................................... External Suction Strainer and Canister Filter

Remote Auxiliary Hydraulic Valves

Number .........................................................................................2 Standard, 3/4 Optional

Type .................................... ISO, 1

2 ND

ST 4 Position, w/Float, Motor, Kickout and Flow Control

4 Position w/Float, Kickout, Zero Leak and Flow Control

10

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

HYDRAULICS AND HITCH (Cont.)

Three-Point Hitch

ASAE Hitch Category.....................................................................................................II/III

Hitch Lower Links

Standard ........................................................................................................Extendable

Number of Lift Cylinders......................................................................................2, External

Controls

Armrest ....................................................... Height/Depth, Raise/Lower, Transport Lock

Right Side Console ...........................Position/Draft Intermix, Maximum Height of Raise,

Rate of Drop, Active Transport

External ...............................................Raise and Lower Buttons on Both Rear Fenders

Draft Sensing .............................................................................Electronic Lower Link Pins

Lift Capacity @ 24 in lb (kg) ........................................7,110 (3225), 8,884 (4030) Optional

Type of Stabilizers ..............................................................................................Telescopic

Drawbar

Type

Row Crop.................................................................................... Narrow Swing w/Clevis

Maximum Vertical Static Load

Row Crop lbs (kg) ....................................................................................... 3,821 (1733)

11

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

OPERATOR AREA

Cab and Controls

Type ................................................................Isolation-Mounted Cab with A/C and Heater

Glass Area sq ft ...............................................................................................................61

Sound Level in Cab dB (A)...............................................................................................71

Pedals ..................................................................................................................Pendulum

Steering Wheel ............................................................................................. Tilt/Telescope

Roll Over Protective Structure (ROPS) .........................................................Integral w/Cab

Seat..............................................................Deluxe, Air Suspension, Swivel and Seat Belt

Instructor’s Seat ...........................................................................w/Backrest and Seat Belt

Instrumentation

Gauges ...........................................Tachometer, Fuel, Temperature (Coolant), Hourmeter

Digital Readouts............................... PTO Speed, Ground Speed, Dynashuttle ® A, B, C, D

Warning Lights ................. Alternator Charge, Engine Oil Pressure, Air Cleaner Restriction

Differential Lock Engage, High Beam, Directional & Hazard Lights,

Parking Brake, Transmission Oil Low Pressure,

Hydraulic Filter, 4WD Engage, Transmission High Range,

PTO Engage 540, 1000, Economy

ELECTRICAL SYSTEM

Starting and Charging

Type of System ............................................................................ 12-Volt Negative Ground

Alternator .............................................................................................................. 120 Amp

Starter ...................................................................................................................... 3.0 kW

Battery.......................................................................................................... Two - 600CCA

Lighting

Front......................................................................... 2 Front Grille Hi/Lo Beam Headlights,

2 Double Element Field Lights Above Windshield,

2 Field Lights on Hand Rail

Rear ................................................... 2 Double Element Field Lights Above Rear Window

Hazard Flashers...............................Red Tail Lights, Flashing Safety/Turn Indicator Lights

Trailer Plug....................................................... Standard, Rear-Mounted 7 Terminal ASAE

Horn ...................................................................................................................... Standard

12

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

CAPACITIES

Engine

Crankcase w/Filter qt (L) .................................................................................... 15.3 (14.5)

Fuel Tank gal (L)

Standard ............................................................................................................ 71 (270)

Cooling System qt (L)............................................................................................ 29.6 (28)

Power Train

Transmission and Final Drives

AutoPower IV ® Transmission gal (L)................................................................. 17.7 (67)

Power Steering System............................................................... Common w/Transmission

Hydraulic System ........................................................................ Common w/Transmission

4WD Differential qt (L)............................................................................................... 6.3 (6)

Suspended 4WD Differential qt (L) ........................................................................... 9 (8.5)

4WD Planetary Final Drives - Each qt (L) ............................................................ 0.7 (0.66)

13

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

DIMENSIONS AND WEIGHTS - 2WD Cab

With 18.4R38 Rear and 10.00 x 16 Front Tires

Dimensions

Wheel Base [B] in (mm) .................................................................................. 112.1 (2848)

Overall Length [A] in (mm) .............................................................................. 168.5 (4279)

Overall Height

Top of Cab [C] in (mm) .............................................................................. 112.8 (2865)

Overall Width [D]

Minimum in (mm) .......................................................................................... 81.1 (2060)

Maximum in (mm) ....................................................................................... 107.4 (2728)

Rear Axle Flange to Flange [H]..................................................................... 69.8 (1772)

Ground Clearance

Under Drawbar [E] in (mm) ............................................................................. 15.4 (392)

Weights

Approximate Shipping Weight

AutoPower IV ® lb (kg) ............................................................................... 10,730 (4867)

14

SPECIFICATIONS

CHALLENGER MT525B AUTOPOWER IV ®

DIMENSIONS AND WEIGHTS – 4WD Cab

With 18.4R38 Rear and 14.9R28 Front Tires

Dimensions

Wheel Base [A] in (mm) .................................................................................. 109.5 (2780)

Overall Length [B] in (mm) .............................................................................. 171.0 (4344)

Overall Height

Top of Cab [C] in (mm) .............................................................................. 112.8 (2865)

Overall Width [D]

Minimum in (mm) .......................................................................................... 81.1 (2060)

Maximum in (mm) ....................................................................................... 107.4 (2728)

Rear Axle Flange to Flange [H]..................................................................... 69.8 (1772)

Ground Clearance

Under Drawbar [E] in (mm) ............................................................................. 15.4 (392)

Weights

Approximate Shipping Weight

AutoPower IV ® lb (kg) ............................................................................... 11,546 (5237)

15

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

GENERAL

Make ................................................................................................................... Challenger

Model ......................................................................................................................... MT535B

Class ......................................................................................................... Mid Size Row Crop

Chassis Type.................................................................Isolation-Mounted Cab, 2WD or 4WD

PTO AND DRAWBAR PERFORMANCE

PTO hp @ Rated Engine rpm hp (kW) ......................................................105 (78.3) @ 2,200

Fuel Consumption @ Rated Engine rpm gph (lph) ..............................................................

Fuel Consumption @ Rated Engine rpm hp h/gal (kW.h/l) ..................................................

PTO hp @ Standard PTO rpm hp (kW)....................................................................................

Fuel Consumption @ Standard PTO rpm gph (lph) .............................................................

Fuel Consumption @ Standard PTO rpm hp h/gal (kW.h/l) .................................................

Maximum Drawbar hp (Unballasted) (PFA) hp (kW) ................................................................

Fuel Consumption @ Maximum DBhp gph (lph)..................................................................

Fuel Consumption @ Maximum DBhp hp·h/gal (kW.h/l)......................................................

Maximum PTO Torque @ Rated Speed lbf-ft (N·m).................................................................

Maximum PTO Torque @ rpm lbf-ft (N·m) ...............................................................................

PTO Torque Rise .....................................................................................................................

Official Test ....................................................................................... Manufacturer’s Estimate

ENGINE GENERAL

Model ............................................................................................................. Caterpillar 3056

Type .......................................................................... In-Line, 4-Cycle, Direct Injection, Diesel

Cylinder Head Design .................................................One Piece, Cast Iron, Overhead Valve

Number of Cylinders...............................................................................................................6

Bore in (mm)............................................................................................................ 3.94 (100)

Stroke in (mm)......................................................................................................... 5.00 (127)

Displacement CID (L) .......................................................................................... 365 (5.985L)

Compression Ratio........................................................................................................17.5: 1

Aspiration ..........................................................................Turbocharged - Charge Air Cooled

Starting Aid........................................................................................................... Thermostart

Block Heater.....................................................................750 Watt Coolant Heater (Optional)

Challenger has a company policy of continuous improvement; therefore,

Specifications are subject to change without notice.

16

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

ENGINE SYSTEMS

Cooling System

Type ........................................................................ Pressurized Liquid, Forced Circulation

Temperature Control ..........................................................................................Thermostat

Fan

Number of Blades......................................................................................................9

Diameter in (mm)........................................................................................ 21.6 (550)

Drive ............................................................................................................... Viscous

Air Intake System

Intake Location................................................................................................. Top of Hood

Air Cleaner

Type.............................................................................................Dry Donaldson FPG10

Number of Elements ........................................................ 2: 1 Primary and 1 Secondary

Material..................................................................................................... Pleated Paper

Restriction Indicator ...................................................................................Warning Light

Exhaust System

Type ................................................................................ Vertical, at Right, Front Cab Post

Muffler Location .............................................Integral w/External Elbow and Vertical Stack

Fuel Injection System

Type of Injection......................................................................................................... Direct

Injection Pump ...........................................................................................................Bosch

Type........................................................................................................... Rotary VP 40

Drive ............................................................................................................Timing Gear

Injectors ......................................................................................... Bosch DSLA Multi-Hole

Governor

Type.................................................................................................................Electronic

Governed Speed Range rpm .........................................................................800 – 2350

Rated Engine rpm ........................................................................................................2200

Lubrication System

Type ................................................................ Full Pressure, Full Flow w/Bypass & Cooler

Filter .......................................................................................................... Spin-on Canister

Number of Filters ...............................................................................................................2

Pump Type...................................................................................................................Gear

Pump Drive ........................................................................................................ Crankshaft

17

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

ENGINE SYSTEMS (Cont.)

Crankcase, Cylinder Block, & Cylinder Head

Cylinder Block .................................................... Cast Iron, Six-Cylinder Parent Bore Block

Cylinder Head .............................................................. One-Piece, Cast, Overhead Valves

Pistons ...........................................................Cast Aluminum Alloy, Controlled Expansion,

Top Ring Insert, Re-Entrant Bowl

Crankshaft............................................................................................... Cold Drop Forged

Number of Main Bearings ..................................................................................................7

POWER TRAIN

Clutch

AutoPower IV ® Transmission Tractors

Type.........................................................................................................Wet, Multi-Disc

Number of Discs ............................................................................................................5

Main Disc Diameter in (mm) ................................................................................ 9 (230)

Control ................................................. Foot Pedal and PowerControl Modulating Valve

Actuation...........................................................................................................Hydraulic

Free-Play Adjustment ................................................................................Self-Adjusting

Type.......................................................Inching Pedal, Electronic Transmission Control

Transmission

AutoPower IV ®

Type....................................................Mechanical, Transmission w/4-Speed Powershift

PowerShuttle............................................................................ Left Side of Steering Wheel

Speeds ..................................................................................... 32 Forward, 32 Reverse

Gears................................................................................ 4 Synchronized, 4 Powershift

Ranges ................................................................ 2 Synchromesh and Dual Wet Clutch,

Electronic Controlled Hydraulic Shuttle

Creeper...................................................................................... Optional, 4:1 Reduction

Differential and Final Drive

Type ........................................................ Primary Reduction - Spiral Hypoid Ring & Pinion

Secondary Reduction – Planetary Gear Set

Differential Lock

Type.......................................................................... Sliding Collar, Engage On-The-Go

Engagement ........................................................................................ Electro-Hydraulic

Final Drive............................................................................................... Inboard Planetary

18

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Differential and Final Drive (Cont.)

Brakes

Rear..................................................................................................... Inboard Wet Disc

Actuation...........................................................................................................Hydraulic

Parking Brake .....................................Hand Operated Lever, Multi-Disc, Acts on Pinion

AutoPower IV® Transmission

Travel Speeds @ Rated Engine rpm (18.4R38 REAR TIRES)

1 2 3 4 mph (kph) mph (kph) mph (kph) mph (kph)

Trans.

Speed

A

Forward B

Turtle C

D

A

Forward B

Rabbit C

D

1.32 (2.12)

1.54 (2.48)

1.82 (2.93)

2.13 (3.43)

4.94 (7.95)

5.78 (9.30)

6.82 (10.98)

7.98 (12.85)

1.99 (3.20)

2.33 (3.75)

2.75 (4.43)

3.21 (5.18)

7.46 (12.01)

8.73 (14.05)

10.31 (16.59)

12.07 (19.42)

2.95 (4.74)

3.45 (5.55)

4.07 (6.55)

4.77 (7.67)

11.05 (17.78)

12.93 (20.81)

15.26 (24.56)

17.86 (28.75)

4.57 (7.36)

5.35 (8.61)

6.32 (10.17)

7.39 (11.90)

17.14 (27.58)

20.06 (32.28)

23.67 (38.10)

A

Reverse B

Turtle C

D

A

Reverse B

Rabbit C

D

1.32 (2.12)

1.54 (2.48)

1.82 (2.93)

2.13 (3.43)

4.94 (7.95)

5.78 (9.30)

6.82 (10.98)

7.98 (12.85)

1.99 (3.20)

2.33 (3.75)

2.75 (4.43)

3.21 (5.18)

7.46 (12.01)

8.73 (14.05)

10.31 (16.59)

12.07 (19.42)

2.95 (4.74)

3.45 (5.55)

4.07 (6.55)

4.77 (7.67)

11.05 (17.78)

12.93 (20.81)

15.26 (24.56)

17.86 (28.75)

Standard Speed x .25 = Creeper Speed (Turtle Range Only)

4.57 (7.36)

5.35 (8.61)

6.32 (10.17)

7.39 (11.90)

17.14 (27.58)

20.06 (32.28)

26.67 (38.10)

19

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Rear Axle

Type ..........................................................................................................................Flange

Tread Settings in (mm)

Welded Steel .......................................................................... 69.7 (1771) – 76.9 (1952)

Manual Adjust Steel................................................................ 58.9 (1495) – 86.6 (2199)

Cast PAVT ............................................................................. 56.9 (1445) – 90.6 (2301)

Optional............................................................................................................Bar 82”/113”

Diameter in (mm) .................................................................................................... 3.2 (82)

Tread Settings

Short Axle – Steel Min/Max, in (mm) ..................................... 62.6 (1590) to 87.0 (2215)

Short Axle – Cast Semi Dish Min/Max, in (mm) ..................... 55.5 (1409) to 80.0 (2032)

Short Axle – Cast Flat Min/Max, in (mm) ............................... 66.6 (1691) to 91.0 (2311)

Long Axle – Steel Min/Max, in (mm) .................................... 62.6 (1590) to 112.1 (2848)

Long Axle – Cast Semi Dish Min/Max, in (mm).................... 55.5 (1409) to 105.1 (2670)

Long Axle – Cast Flat Min/Max, in (mm).............................. 66.6 (1691) to 116.3 (2953)

Maximum Permissible Rear Tire Diameter in (mm).............................................. 72 (1834)

Maximum Permissible Axle Static Load Limit lb (kg)..................................... 12,897 (5850)

2WD Adjustable Front Axle

Type ....................................................................................Telescopic, Box-In-Box Design

Steering Angle degrees....................................................................................................55

Tread Setting

Adjustment Increments in (mm) ...................................................................... 3.94 (100)

Tread Adjustment Range (10:00 x 16 Tire)

Wheel Turned In in (mm).................................................... 64.1 (1629) – 79.9 (2029)

Wheel Turned Out in (mm) ................................................. 67.2 (1707) – 83.0 (2107)

Wheel Turned In Wide Row Crop in (mm).......................... 73.2 (1861) – 92.9 (2361)

Wheel Turned Out Wide Row Crop in (mm) ....................... 76.4 (1939) – 96.0 (2439)

Maximum Permissible Axle Static Load Limit lb (kg)....................................... 4,652 (2110)

4WD Front Axle

Type ............................................................Center Pivot, Mechanical Drive, Carraro 20.22

Standard ....................................................................................................Fixed Front Axle

Optional............................................................................ Hydraulic Suspended Front Axle

Steering Angle degrees....................................................................................................55

Drive.............................................................................................. Centerline Splined Shaft

Drive Ratio ..................................................................................................................1.328

Method of Engagement....................................... Electro-Hydraulic, Wet, Multi-Disc Clutch

Differential Lock

Type............................................................................................................Sliding Collar

Method of Engagement ............................Electro-Hydraulic, Simultaneous w/Rear Axle

Tread Settings in (mm)................................................................ 61.7 (1567) – 80.8 (2053)

Maximum Permissible Axle Static Load Limit lb (kg)....................................... 7,496 (3400)

20

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Power Take-Off

Type .................................................................................................................Independent

Speeds rpm...........................................................................................................540/1000

Optional.................................................................................................................Economy

Control .........................................................................................Electro-Hydraulic Control

Clutch...........................................................................................................Wet, Multi-Disc

Clutch Disc Diameter in (mm) ............................................................................. 5.31 (135)

Shaft Configuration .................................................................................... Interchangeable

540 rpm in (mm) .............................................................................. 1.375 (35), 6 Spline

1000 rpm in (mm) .......................................................................... 1.375 (35), 21 Spline

Engine/PTO Speed Ratio

540 rpm ....................................................................................540 @ 1980 Engine rpm

1000 rpm ................................................................................1000 @ 2000 Engine rpm

Economy 540/1000..................................................................... 1533/1548 Engine rpm

HYDRAULICS AND HITCH

Closed Center System

Type .............................................................Closed-Center, Pressure, Flow Compensated

Drive....................................................................................................................PTO Shaft

Flow gpm (lpm) (2200 erpm)............................................................................... 29.0 (110)

Pressure psi (bar) .............................................................................................. 2900 (200)

Remote Valves standard (optional)........................................................................... 2 (3,4)

Dual Flow System (Load Sensing)

Type .....................................................................................................................Dual Flow

Drive....................................................................................................................PTO Shaft

Flow gpm (lpm) (2200 erpm)............................................................................... 26.4 (110)

Pressure psi (bar) .............................................................................................. 2900 (200)

Remote Valves standard (optional)........................................................................... 2 (3,4)

Filters

Number ..............................................................................................................................2

Type ............................................................... External Suction Strainer and Canister Filter

Remote Auxiliary Hydraulic Valves

Number .........................................................................................2 Standard, 3/4 Optional

Type .................................... ISO, 1

2 ND

ST 4 Position, w/Float, Motor, Kickout and Flow Control

4 Position w/Float, Kickout, Zero Leak and Flow Control

21

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

HYDRAULICS AND HITCH (Cont.)

Three-Point Hitch

ASAE Hitch Category.....................................................................................................II/III

Hitch Lower Links

Standard ........................................................................................................Extendable

Number of Lift Cylinders......................................................................................2, External

Controls

Armrest ....................................................... Height/Depth, Raise/Lower, Transport Lock

Right Side Console ...........................Position/Draft Intermix, Maximum Height of Raise,

Rate of Drop, Active Transport

External ...............................................Raise and Lower Buttons on Both Rear Fenders

Draft Sensing .............................................................................Electronic Lower Link Pins

Lift Capacity @ 24 in lb (kg) ............................................................................ 9,336 (4235)

Type of Stabilizers ..............................................................................................Telescopic

Drawbar

Type

Row Crop.................................................................................... Narrow Swing w/Clevis

Maximum Vertical Static Load

Row Crop lbs (kg) ....................................................................................... 3,821 (1733)

22

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

OPERATOR AREA

Cab and Controls

Type ................................................................Isolation-Mounted Cab with A/C and Heater

Glass Area sq ft ...............................................................................................................61

Sound Level in Cab dB (A)...............................................................................................71

Pedals ..................................................................................................................Pendulum

Steering Wheel ............................................................................................. Tilt/Telescope

Roll Over Protective Structure (ROPS) .........................................................Integral w/Cab

Seat..............................................................Deluxe, Air Suspension, Swivel and Seat Belt

Instructor’s Seat ...........................................................................w/Backrest and Seat Belt

Instrumentation

Gauges ...........................................Tachometer, Fuel, Temperature (Coolant), Hourmeter

Digital Readouts............................... PTO Speed, Ground Speed, Dynashuttle ® A, B, C, D

Warning Lights ................. Alternator Charge, Engine Oil Pressure, Air Cleaner Restriction

Differential Lock Engage, High Beam, Directional & Hazard Lights,

Parking Brake, Transmission Oil Low Pressure,

Hydraulic Filter, 4WD Engage, Transmission High Range,

PTO Engage 540, 1000, Economy

ELECTRICAL SYSTEM

Starting and Charging

Type of System ............................................................................ 12-Volt Negative Ground

Alternator .............................................................................................................. 120 Amp

Starter ...................................................................................................................... 3.0 kW

Battery......................................................................................................... Two - 600 CCA

Lighting

Front......................................................................... 2 Front Grille Hi/Lo Beam Headlights,

2 Double Element Field Lights Above Windshield,

2 Field Lights on Hand Rail

Rear ................................................... 2 Double Element Field Lights Above Rear Window

Hazard Flashers...............................Red Tail Lights, Flashing Safety/Turn Indicator Lights

Trailer Plug....................................................... Standard, Rear-Mounted 7 Terminal ASAE

Horn ...................................................................................................................... Standard

23

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

CAPACITIES

Engine

Crankcase w/Filter qt (L) .................................................................................... 15.3 (14.5)

Fuel Tank gal (L)

Standard ............................................................................................................ 71 (270)

Cooling System qt (L)............................................................................................ 29.6 (28)

Power Train

Transmission and Final Drives

AutoPower IV ® Transmission gal (L)................................................................. 17.7 (67)

Power Steering System............................................................... Common w/Transmission

Hydraulic System ........................................................................ Common w/Transmission

4WD Differential qt (L)............................................................................................... 6.3 (6)

Suspended 4WD Differential qt (L) ........................................................................... 9 (8.5)

4WD Planetary Final Drives - Each qt (L) .......................................................... . 0.7 (0.66)

24

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

DIMENSIONS AND WEIGHTS - 2WD Cab

With 18.4R38 Rear and 10.00 x 16 Front Tires

Dimensions

Wheel Base [B] in (mm) .................................................................................. 112.1 (2848)

Overall Length [A] in (mm) .............................................................................. 168.5 (4279)

Overall Height

Top of Cab [C] in (mm) .............................................................................. 112.8 (2865)

Overall Width [D]

Minimum in (mm) .......................................................................................... 81.1 (2060)

Maximum in (mm) ....................................................................................... 144.5 (3669)

Rear Axle Flange to Flange [H]..................................................................... 72.2 (1834)

Ground Clearance

Under Drawbar [E] in (mm) ............................................................................. 15.4 (392)

Weights

Approximate Shipping Weight

AutoPower IV ® lb (kg) ............................................................................... 10,988 (4984)

25

SPECIFICATIONS

CHALLENGER MT535B AUTOPOWER IV ®

DIMENSIONS AND WEIGHTS – 4WD Cab

With 18.4R38 Rear and 14.9R28 Front Tires

Dimensions

Wheel Base [A] in (mm) .................................................................................. 109.5 (2780)

Overall Length [B] in (mm) .............................................................................. 171.0 (4344)

Overall Height

Top of Cab [C] in (mm) .............................................................................. 112.8 (2865)

Overall Width [D]

Minimum in (mm) .......................................................................................... 81.1 (2060)

Maximum in (mm) ....................................................................................... 144.5 (3669)

Rear Axle Flange to Flange [H]..................................................................... 72.2 (1835)

Ground Clearance

Under Drawbar [E] in (mm) ............................................................................. 15.4 (392)

Weights

Approximate Shipping Weight

AutoPower IV ® lb (kg) ............................................................................... 11,949 (5420)

26

SPECIFICATIONS

CHALLENGER MT545B AUTOPOWER IV ®

GENERAL

Make ................................................................................................................... Challenger

Model ......................................................................................................................... MT545B

Class ......................................................................................................... Mid Size Row Crop

Chassis Type.................................................................Isolation-Mounted Cab, 2WD or 4WD

PTO AND DRAWBAR PERFORMANCE

PTO hp @ Rated Engine rpm hp (kW) ......................................................115 (85.8) @ 2,200

Fuel Consumption @ Rated Engine rpm gph (lph) ..............................................................

Fuel Consumption @ Rated Engine rpm hp h/gal (kW.h/l) ..................................................

PTO hp @ Standard PTO rpm hp (kW)....................................................................................

Fuel Consumption @ Standard PTO rpm gph (lph) .............................................................

Fuel Consumption @ Standard PTO rpm hp h/gal (kW.h/l) .................................................

Maximum Drawbar hp (Unballasted) (PFA) hp (kW) ................................................................

Fuel Consumption @ Maximum DBhp gph (lph)..................................................................

Fuel Consumption @ Maximum DBhp hp·h/gal (kW.h/l)......................................................

Maximum PTO Torque @ Rated Speed lbf-ft (N·m).................................................................

Maximum PTO Torque @ rpm lbf-ft (N·m) ...............................................................................

PTO Torque Rise .....................................................................................................................

Official Test ....................................................................................... Manufacturer’s Estimate

ENGINE GENERAL

Model ............................................................................................................. Caterpillar 3056

Type .......................................................................... In-Line, 4-Cycle, Direct Injection, Diesel

Cylinder Head Design .................................................One Piece, Cast Iron, Overhead Valve

Number of Cylinders...............................................................................................................6

Bore in (mm)............................................................................................................ 3.94 (100)

Stroke in (mm)......................................................................................................... 5.00 (127)

Displacement CID (L) .......................................................................................... 365 (5.985L)

Compression Ratio........................................................................................................17.5: 1

Aspiration ..........................................................................Turbocharged - Charge Air Cooled

Starting Aid........................................................................................................... Thermostart

Block Heater.....................................................................750 Watt Coolant Heater (Optional)

Challenger has a company policy of continuous improvement; therefore,

Specifications are subject to change without notice.

27

SPECIFICATIONS

CHALLENGER MT545B AUTOPOWER IV ®

ENGINE SYSTEMS

Cooling System

Type ........................................................................ Pressurized Liquid, Forced Circulation

Temperature Control ..........................................................................................Thermostat

Fan

Number of Blades......................................................................................................9

Diameter in (mm)........................................................................................ 21.6 (550)

Drive ............................................................................................................... Viscous

Air Intake System

Intake Location................................................................................................. Top of Hood

Air Cleaner

Type.............................................................................................Dry Donaldson FPG10

Number of Elements ........................................................ 2: 1 Primary and 1 Secondary

Material..................................................................................................... Pleated Paper

Restriction Indicator ...................................................................................Warning Light

Exhaust System

Type ................................................................................ Vertical, at Right, Front Cab Post

Muffler Location .............................................Integral w/External Elbow and Vertical Stack

Fuel Injection System

Type of Injection......................................................................................................... Direct

Injection Pump ...........................................................................................................Bosch

Type........................................................................................................... Rotary VP 40

Drive ............................................................................................................Timing Gear

Injectors ......................................................................................... Bosch DSLA Multi-Hole

Governor

Type.................................................................................................................Electronic

Governed Speed Range rpm .........................................................................800 – 2350

Rated Engine rpm ........................................................................................................2200

Lubrication System

Type ................................................................ Full Pressure, Full Flow w/Bypass & Cooler

Filter .......................................................................................................... Spin-on Canister

Number of Filters ...............................................................................................................2

Pump Type...................................................................................................................Gear

Pump Drive ........................................................................................................ Crankshaft

28

SPECIFICATIONS

CHALLENGER MT545B AUTOPOWER IV ®

ENGINE SYSTEMS (Cont.)

Crankcase, Cylinder Block, & Cylinder Head

Cylinder Block .................................................... Cast Iron, Six-Cylinder Parent Bore Block

Cylinder Head .............................................................. One-Piece, Cast, Overhead Valves

Pistons ...........................................................Cast Aluminum Alloy, Controlled Expansion,

Top Ring Insert, Re-Entrant Bowl

Crankshaft............................................................................................... Cold Drop Forged

Number of Main Bearings ..................................................................................................7

POWER TRAIN

Clutch

AutoPower IV ® Transmission Tractors

Type.........................................................................................................Wet, Multi-Disc

Number of Discs ............................................................................................................5

Main Disc Diameter in (mm) ................................................................................ 9 (230)

Control ................................................. Foot Pedal and PowerControl Modulating Valve

Actuation...........................................................................................................Hydraulic

Free-Play Adjustment ................................................................................Self-Adjusting

Type.......................................................Inching Pedal, Electronic Transmission Control

Transmission

AutoPower IV ®

Type....................................................Mechanical, Transmission w/4-Speed Powershift

PowerShuttle............................................................................ Left Side of Steering Wheel

Speeds ..................................................................................... 32 Forward, 32 Reverse

Gears................................................................................ 4 Synchronized, 4 Powershift

Ranges ................................................................ 2 Synchromesh and Dual Wet Clutch,

Electronic Controlled Hydraulic Shuttle

Creeper...................................................................................... Optional, 4:1 Reduction

Differential and Final Drive

Type ........................................................ Primary Reduction - Spiral Hypoid Ring & Pinion

Secondary Reduction – Planetary Gear Set

Differential Lock

Type.......................................................................... Sliding Collar, Engage On-The-Go

Engagement ........................................................................................ Electro-Hydraulic

Final Drive............................................................................................... Inboard Planetary

29

SPECIFICATIONS

CHALLENGER MT545B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Differential and Final Drive (Cont.)

Brakes

Rear..................................................................................................... Inboard Wet Disc

Actuation...........................................................................................................Hydraulic

Parking Brake .....................................Hand Operated Lever, Multi-Disc, Acts on Pinion

AutoPower IV® Transmission

Travel Speeds @ Rated Engine rpm (20.8R38 REAR TIRES)

1 2 3 4 mph (kph) mph (kph) mph (kph) mph (kph)

Trans.

Speed

A

Forward B

Turtle C

D

A

Forward B

Rabbit C

D

1.37 (2.21)

1.60 (2.59)

1.90 (3.06)

2.22 (3.58)

5.15 (8.29)

6.02 (9.70)

7.11 (11.45)

8.32 (13.40)

2.07 (3.34)

2.42 (3.91)

2.80 (4.62)

3.35 (5.40)

7.77 (12.52)

9.10 (14.65)

10.74 (17.30)

12.58 (20.25)

3.07 (4.95)

3.59 (5.79)

4.24 (6.83)

4.97 (8.00)

11.52 (18.54)

13.48 (21.70)

15.91 (25.61)

18.62 (29.98)

4.76 (7.67)

5.57 (8.98)

6.58 (10.60)

7.71 (12.41)

17.87 (28.76)

20.91 (33.66)

24.68 (39.73)

A

Reverse B

Turtle C

D

A

Reverse B

Rabbit C

D

1.37 (2.21)

1.60 (2.59)

1.90 (3.06)

2.22 (3.58)

5.15 (8.29)

6.02 (9.70)

7.11 (11.45)

8.32 (13.40)

2.07 (3.34)

2.42 (3.91)

2.80 (4.62)

3.35 (5.40)

7.77 (12.52)

9.10 (14.65)

10.74 (17.30)

12.58 (20.25)

3.07 (4.95)

3.59 (5.79)

4.24 (6.83)

4.97 (8.00)

11.52 (18.54)

13.48 (21.70)

15.91 (25.61)

18.62 (29.98)

Standard Speed x .25 = Creeper Speed (Turtle Range Only)

4.76 (7.67)

5.57 (8.98)

6.58 (10.60)

7.71 (12.41)

17.87 (28.76)

20.91 (33.66)

24.68 (39.73)

30

SPECIFICATIONS

CHALLENGER MT545B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Rear Axle

Type ....................................................................................................................... Bar Axle

Axle Length

Standard in (mm) ............................................................................................. 82 (2235)

Optional in (mm) ............................................................................................ 113 (2870)

Diameter in (mm) .................................................................................................... 3.2 (82)

Tread Settings

Short Axle – Steel Min/Max, in (mm) ..................................... 62.6 (1590) to 87.0 (2215)

Short Axle – Cast Semi Dish Min/Max, in (mm) ..................... 55.5 (1409) to 80.0 (2032)

Short Axle – Cast Flat Min/Max, in (mm) ............................... 66.6 (1691) to 91.0 (2311)

Long Axle – Steel Min/Max, in (mm) .................................... 62.6 (1590) to 112.1 (2848)

Long Axle – Cast Semi Dish Min/Max, in (mm).................... 55.5 (1409) to 105.1 (2670)

Long Axle – Cast Flat Min/Max, in (mm).............................. 66.6 (1691) to 116.3 (2953)

Optional.....................................................................................................................Flange

Tread Settings in (mm)

Welded Steel ...................................................................... 69.7 (1771) – 76.9 (1952)

Manual Adjust Steel............................................................ 58.9 (1495) – 86.6 (2199)

Cast PAVT ......................................................................... 56.9 (1445) – 90.6 (2301)

Maximum Permissible Rear Tire Diameter in (mm).............................................. 72 (1834)

Maximum Permissible Axle Static Load Limit lb(kg)...................................... 12,897 (5850)

2WD Adjustable Front Axle

Type ....................................................................................Telescopic, Box-In-Box Design

Steering Angle degrees....................................................................................................55

Tread Setting

Adjustment Increments in (mm) ...................................................................... 3.94 (100)

Tread Adjustment Range (10:00 X 16 Tire)

Wheel Turned In in (mm).................................................... 64.1 (1629) – 79.9 (2029)

Wheel Turned Out in (mm) ................................................. 67.2 (1707) – 83.0 (2107)

Wheel Turned In Wide Row Crop in (mm).......................... 73.2 (1861) – 92.9 (2361)

Wheel Turned Out Wide Row Crop in (mm) ....................... 76.4 (1939) – 96.0 (2439)

Maximum Permissible Axle Static Load Limit lb (kg)....................................... 4,652 (2110)

4WD Front Axle

Type ............................................................Center Pivot, Mechanical Drive, Carraro 20.29

Standard ....................................................................................................Fixed Front Axle

Optional............................................................................ Hydraulic Suspended Front Axle

Steering Angle degrees....................................................................................................55

Drive.............................................................................................. Centerline Splined Shaft

Drive Ratio ..................................................................................................................1.335

Method of Engagement....................................... Electro-Hydraulic, Wet, Multi-Disc Clutch

Differential Lock

Type............................................................................................................Sliding Collar

Method of Engagement ............................Electro-Hydraulic, Simultaneous w/Rear Axle

Tread Settings in (mm)................................................................ 61.2 (1554) – 89.2 (2265)

Maximum Permissible Axle Static Load Limit lb (kg)....................................... 7,496 (3400)

31

SPECIFICATIONS

CHALLENGER MT545B AUTOPOWER IV ®

POWER TRAIN (Cont.)

Power Take-Off

Type .................................................................................................................Independent

Speeds rpm...........................................................................................................540/1000

Optional.................................................................................................................Economy