Plasma surface treatment of artificial orthopedic and cardiovascular

advertisement

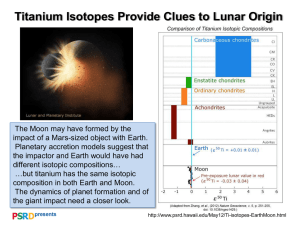

Surface & Coatings Technology 201 (2007) 5601 – 5606 www.elsevier.com/locate/surfcoat Plasma surface treatment of artificial orthopedic and cardiovascular biomaterials Paul K. Chu ⁎ Department of Physics and Materials Science, City University of Hong Kong, Tat Chee Avenue, Kowloon, Hong Kong Available online 8 August 2006 Abstract Plasma surface modification has become a popular method to modify the surface structure and biological properties of biomaterials. By modifying selective surface mechanical and biological properties, conventional materials can be redesigned with their favorable bulk attributes retained. Plasma surface modification can enhance the multi-functionality, mechanical properties, as well as biocompatibility of artificial biomaterials and medical implants. Here, our recent research work on plasma modification of orthopedic materials including titanium and nickel– titanium shape memory alloys as well as diamond-like carbon as cardiovascular materials is described. NiTi alloys that possess shape memory and super-elastic properties are of interest in spinal deformity correction. Shape recovery inside the human body allows for less traumatic gradual correction while obviating the needs for multiple surgeries. However, leaching of harmful nickel ions from the materials causes health hazards and plasma implantation is an excellent means to create a graded barrier layer to impede Ni out-diffusion and improve the corrosion resistance. Our latest results demonstrate that the shape recovery property is not compromised with the plasma treatment. Also described are our results on titanium implanted with calcium and sodium for enhancement of the surface biological properties. With regard to cardiovascular materials, the two main requirements are good surface mechanical properties and blood compatibility. Diamond-like carbon (DLC) is a potential material in artificial heart valve and our recent studies suggest that doping DLC with biological friendly elements such as nitrogen and phosphorus can improve the blood compatibility of the materials. © 2006 Elsevier B.V. All rights reserved. PACS: 52.75.R; 52.65.R; 52.65.C; 61.72.T Keywords: Plasma implantation; Biomaterials; Titanium; Nickel–titanium shape memory alloys; Diamond-like carbon 1. Introduction Development of new biomaterials is an arduous and time consuming process comprising many steps: materials selection and modification, structural analysis and property evaluation/ optimization, in vitro tests, in vivo tests (short term and long term), clinical trials, and manufacturing of the final products after approval. A shorter route is to employ existing biomaterials and selectively alter the surface biological properties to cater to particular applications. For example, in orthopedic applications, the surface of hard materials can be made more cyto-compatible to spur more effective growth and proliferation of bone cells. With regard to cardiovascular applications, the main issue is blood compatibility and serious thrombosis on a ⁎ Tel.: +852 27887724; fax: +852 27889549, +852 27887830. E-mail address: paul.chu@cityu.edu.hk. 0257-8972/$ - see front matter © 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.surfcoat.2006.07.003 failed heart valve, for instance, results in immobilization. Therefore, the blood compatibility of such materials must be improved and surface modification provides a means to tailor selective surface characteristics without affecting the desirable properties of the bulk materials. The choice of the technique frequently depends on the reliability, reproducibility, and product yields [1,2]. Plasma surface modification, a simpler and more environmentally green than chemical treatment, has become one of the preferred techniques in biomaterials research [3,4]. Among the various plasma treatment techniques, plasma immersion ion implantation and deposition (PIII&D) that was first introduced in the 1980s to circumvent the line-of-sight restriction of conventional beam-line ion implantation [5] offers advantages such as high efficiency, non-line-of-sight capability, and small instrument footprint [6,7]. It has recently been applied to orthopedic materials [8–10], hard tissue replacements [11], amorphous carbon films [12,13], and polymers [14–16]. In this 5602 P.K. Chu / Surface & Coatings Technology 201 (2007) 5601–5606 Fig. 1. X-ray photos of the spine of the operated goat: (Left) before surgery; (Middle) one day after implantation of a NiTi rod; (Right) one week after surgery. paper, the recent developments in our laboratory pertaining to plasma surface modification of nickel–titanium shape memory alloys, titanium, and doped diamond-like carbon are described. 2. Orthopedic nickel–titanium shape memory alloys Stainless steels are the most popular materials for internal fixation due to the low cost as well as good mechanical and biological properties [17]. In addition, titanium and titanium alloys are prevalent in dental and orthopedic devices [18]. A new class of materials, nickel–titanium (NiTi) alloys, has recently attracted much attention as orthopedic materials because of their distinctive super-elastic and shape memory effects [19– 21] that most other artificial biomaterials do not possess. Studies have shown that NiTi is in general compatible with living tissues [22,23], but adverse effects have also been reported [24]. In particular, severe cell death rate stemming from the poor corrosion resistance and toxic constituents such as Ni in NiTi alloys has been observed [25,26]. It has also been shown that nickel leached from the alloys causes strong allergic reactions in patients with nickel hyper-sensitivity [27,28]. To block Ni outdiffusion, tantalum and oxygen have been introduced into NiTi using plasma techniques [29,30]. Our research group has been actively involved in the plasma treatment of orthopedic NiTi shape alloys. Our previous investigations [31–34] have shown that the corrosion and wear resistance can be enhanced by utilizing acetylene, nitrogen, and oxygen plasma immersion ion implantation (PIII). Compared to conventional coating technologies, PIII does not introduce an abrupt interface and so problems pertaining to film peeling are mitigated. Its none-line-ofsight nature also enables more effective treatment of medical implants with irregular shape. However, it should be noted that due to the limited ion energies, the treated depth is typically quite small, but in applications in which abrasive wear is not encountered, it is an excellent surface modification technique. In this section, we describe our latest results on NiTi treated by PIII. In case of severe spinal deformity, surgeries are needed to straighten the patient's spine. The degree of correction depends on how well the rods are fixed to the spine. A force which is too large can cause fracture and tissue damage. On the other hand, a force that is too small leads to under-correction. Even in optimal cases, the degree of correction seldom exceeds 70% due to the visco-elasticity of biological tissues. Nickel–titanium alloys possess distinctive shape memory and super-elastic properties. That is to say, gradual correction under a constant force can take place inside the human body by using corrective rods made of the materials in spinal surgery, thereby obviating the needs for multiple corrective surgeries. To demonstrate the feasibility of the process, we inserted into a normal goat a NiTi rod which was straight at 15 °C and would attain a curved shape at the body temperature of 37 °C. As shown in Fig. 1, the spine of the goat that was straight before surgery became progressively bent by the constant recovery force of the rod thereby verifying the feasibility of the surgical procedures. To reduce leaching of harmful Ni ions from the NiTi alloy, we perform plasma immersion ion implantation. Our objective is to form a barrier layer consisting of TiC, TiN, or TiO to impede Ni out-diffusion by taking advantage of the preferential formation of Ti–O, Ti–C, or Ti–N bonds thereby depleting Ni from the implanted surfaces [35]. Fig. 2 shows the depth Fig. 2. XPS depth profiles showing the formation of a barrier layer and depletion of Ni from the surface after C, N, or O PIII. P.K. Chu / Surface & Coatings Technology 201 (2007) 5601–5606 5603 Fig. 3. Surfaces of NiTi samples after corrosion tests: (a) Untreated NiTi: (b) C-PIII NiTi, (c) N-PIII NiTi, and (d) O-PIII NiTi. profiles obtained from the carbon, nitrogen, and oxygen PIII NiTi samples clearly showing the barrier layer as well as depletion of Ni from the surface region. To further investigate the corrosion resistance of the barrier layers, corrosion tests based on the ASTM G5-94 electrochemical test protocols were conducted. As shown in Fig. 3, the PIII treated surfaces exhibit substantially less corrosion damage. The test solutions were also analyzed by inductively-coupled plasma mass spectrometry, and as shown in Table 1, the amounts of Ni leached from the plasma-implanted NiTi samples are dramatically reduced. We have also conducted cell culture tests and observed that the PIII sample surfaces are cyto-compatible [32–34]. 3. Calcium plasma-implanted titanium Titanium and titanium alloys are common materials in orthopedic and dental applications because of their relatively low modulus, excellent fatigue strength, excellent formability, good machinability, superior biocompatibility, and reasonable corrosion resistance. However, titanium also has relatively poor wear resistance and bioactivity [36]. Ion implantation has been used to harden the surface and reduce the friction coefficient of titanium in tribological applications, but the metal surface still requires further modification in order to achieve enhanced bioactivity or bone-conductivity [37]. Hanawa et al. investigated early bone formation on calcium-ion-implanted titanium in- serted into rat tibia. Their results reveal that Ca2+ implanted titanium is superior to unimplanted titanium from the perspective of bone conduction [38]. We recently conducted Ca plasma implantation into Ti and observed enhanced bone bioactivity [39]. Fig. 4 shows the plan views of the implanted and unimplanted samples after soaking in a simulated body fluid for 14 days. Some needle-like features that are confirmed to be apatite by X-ray photoelectron spectroscopy (XPS) can be observed on the surface of the titanium sample implanted at 10 kV but no obvious change can be seen on the surface of the unimplanted titanium after immersion in the simulated body fluid. Further studies indicate that upon exposure to air, the implanted calcium is first oxidized and then reacts with water and carbon dioxide to form calcium hydroxide and calcium carbonate on the outermost surface. When the Ca implanted titanium is soaked in a simulated body fluid, calcium hydroxide dissolves Table 1 Ni concentrations in simulated body fluids after corrosion tests determined by inductively-coupled plasma mass spectrometry Sample Ni concentration (ppm) Untreated control Carbon PIII sample Nitrogen PIII sample Oxygen PIII sample 30.23 0.008a 0.012a 0.012a a Near instrumental detection limit. 5604 P.K. Chu / Surface & Coatings Technology 201 (2007) 5601–5606 Fig. 4. Surfaces of the samples soaked in a simulated body fluid for 14 days: (a) un-implanted titanium, (b) Ca plasma-implanted titanium. Fig. 5. SEM micrographs showing the morphology and quantity adherent platelets on: (a) Nitrogen PIII DLC and (b) LTIC. gradually into the solution and hydroxyapatite subsequently forms on the surface. This is believed to be the mechanism of the enhanced surface bioactivity. as they impact the electronic characteristics as well as the biological properties of DLC. In our nitrogen doping experiments, the doped DLC films were synthesized by operating a carbon filtered cathodic arc source in concert with a nitrogen/ argon plasma in an immersion configuration, and doping and 4. Nitrogen and phosphorus doped diamond-like carbon coatings PIII&D can also be used to improve the blood compatibility of artificial cardiovascular materials. Low-temperature isotropic pyrolytic carbon (LTIC) is currently the most widely accepted materials, but the materials are quite brittle and the blood compatibility is still inadequate. Consequently, patients implanted with heart valves made of LTIC take anti-coagulation medication and so there is a need to develop new artificial heart valve materials that possess better blood compatibility and mechanical durability. Materials that have received attention include TiN, TiO2, and diamond-like carbon (DLC) thin films [40–44]. In particular, diamond-like carbon (DLC) is a suitable material on account of their chemical inertness, low coefficient of friction, high wear resistance, and moderate biocompatibility [45,46]. Some of the properties of DLC can be enhanced by doping with adventitious elements [47,48]. Two impurity elements, namely nitrogen and phosphorus [49], are of particular interest Fig. 6. Quantities of adhered platelets and activated platelets on the surface of LTIC, DLC and P-doped DLC. P.K. Chu / Surface & Coatings Technology 201 (2007) 5601–5606 film fabrication were carried out in the same vacuum chamber without breaking vacuum. Our data show that an optimized ratio of nitrogen to argon is necessary to achieve superior surface properties [50]. The blood compatibility of the materials was evaluated utilizing in vitro platelet adhesion tests. Fig. 5 depicts the state of the adhered platelets on the nitrogen-doped DLC and LTIC. In addition to a smaller number, most of the adhered platelets on the N-doped DLC films are isolated and round exhibiting very little destruction. In contrast, most of the platelets on the LTIC exhibit pseudopodium indicative of some extent of activation. Our data suggest that an optimal fraction of sp2 bonding is desirable and that graphitization induced degradation of the wettability properties should be avoided. In a separate experiment, we produced phosphorus doped DLC and investigated the surface blood compatibility by monitoring platelet adhesion and activation. Fig. 6 shows the amounts of adhered platelets on LTIC, undoped DLC control, as well as Pdoped DLC films after 20 min incubation. The highest number of adhered platelet is found on the undoped DLC film. Moreover, most of the adherent platelets on the undoped DLC film are in aggregation exhibiting spreading pseudopodium [51]. Further analysis shows that the surface of P-doped DLC has excellent wettability. Hence, one of the causes for the good hemo-compatibility is that the P-doped DLC coating surface significantly minimizes the interactions with blood plasma proteins giving rise to slight changes in the conformation of adsorbed plasma proteins and preferentially adsorbed albumin. 5. Conclusion Plasma surface modification is a versatile technique biomaterials engineering. One of the advantages is that individual surface biological properties can be easily altered without changing the bulk properties of the biomaterials such as strength. In this paper, we describe the recent applications of plasma immersion ion implantation to NiTi orthopedic materials, Ti alloys, and diamond-like carbon films. The results show that PIII produces an effective surface barrier to mitigate nickel outdiffusion, enhances the surface bioactivity of Ti, and improves the surface blood compatibility of diamond-like carbon. Acknowledgements The work was jointly supported by Hong Kong Research Grant Council (RGC) Competitive Earmarked Research Grant (CERG) CityU 1120/04E, National Science Foundation of China and RGC (NSFC/RGC) Joint Research Scheme N_CityU 101/03, and RGC Central Allocation Group Research Grant CityU 1/04C. References [1] R.N.S. Sodhi, J. Electron Spectrosc. Relat. Phenom. 81 (1996) 269. [2] P. Sioshansi, Mater. Sci. Eng. 90 (1987) 373. [3] P.K. Chu, J.Y. Chen, L.P. Wang, N. Huang, Mater. Sci. Eng., R Rep. 36 (5–6) (2002) 143. [4] Y. Okabe, S. Kurihara, T. Yajima, Y. Seki, I. Nakamura, I. Takano, Surf. Coat. Technol. 196 (1–3) (2005) 303. 5605 [5] J.R. Conrad, J.L. Radtke, R.A. Dodd, F.J. Worzala, N.C. Tran, J. Appl. Phys. 62 (1987) 4591. [6] P.K. Chu, S. Qin, C. Chan, N.W. Cheung, L.A. Larson, Mater. Sci. Eng., R Rep. 17 (1996) 207. [7] A. Anders (Ed.), Handbook of Plasma Immersion Ion Implantation and Deposition, John Wiley and Sons, New York, 2000. [8] R. Wei, T. Booker, C. Rincon, J. Arps, Surf. Coat. Technol. 186 (1–2) (2004) 305. [9] B.R. Lanning, R. Wei, Surf. Coat. Technol. 186 (1–2) (2004) 314. [10] S. Mandl, J.W. Gerlach, B. Rauschenbach, Surf. Coat. Technol. 196 (1–3) (2005) 293. [11] X.Y. Liu, P.K. Chu, C.X. Ding, Mater. Sci. Eng., R Rep. 47 (2–4) (2004) 49. [12] P. Yang, J.Y. Chen, Y.X. Leng, H. Sun, N. Huang, P.K. Chu, Surf. Coat. Technol. 186 (1–2) (2004) 125. [13] S.C.H. Kwok, J. Wang, P.K. Chu, Diamond Relat. Mater. 14 (1) (2005) 78. [14] D.R. McKenzie, K. Newton-McGee, P. Ruch, M.M. Bilek, B.K. Gan, Surf. Coat. Technol. 186 (1–2) (2004) 245. [15] M. Ueda, K.G. Kostov, A.F. Beloto, N.F. Leite, K.G. Grigorov, Surf. Coat. Technol. 186 (1–2) (2004) 295. [16] W. Zhang, P.K. Chu, J.H. Ji, Y.H. Zhang, X.Y. Liu, R.K.Y. Fu, P.C.T. Ha, Q. Yan, Biomaterials 2 (1) (2006) 44. [17] J. Disegi, L. Eschbach, Injury 31 (S4) (2000) 4. [18] J. Woodman, J. Jacobs, J. Galante, J. Orthop. Res. 1 (4) (1984) 421. [19] F.X. Gil, J.A. Planell, J.M. Manero, J. Mater. Sci., Mater. Med. 7 (1996) 403. [20] S. Kujala, J. Ryhanen, A. Danilov, J. Tuukkanen, Biomaterials 24 (25) (2003) 4691. [21] M.F. Chen, X.J. Yang, R.X. Hu, Z.D. Cui, H.C. Man, Mater. Sci. Eng., C, Biomim. Mater., Sens. Syst. 24 (4) (2004) 497. [22] A. Kapanen, J. Ilvesaro, A. Danilov, J. Ryhanen, P. Lehenkari, J. Tuukkanen, Biomaterials 23 (3) (2002) 645. [23] D. Bogdanski, M. Koller, D. Muller, G. Muhr, M. Bram, H.P. Buchkremer, D. Stover, J. Choi, M. Epple, Biomaterials 23 (23) (2002) 4549. [24] W. Jia, M.W. Beatty, R.A. Reinhardt, T.M. Petro, D.M. Cohen, C.R. Maze, E.A. Strom, M. Hoffman, J. Biomed. Mater. Res. 48 (4) (1999) 488. [25] M. Es-Souni, H. Fischer-Brandies, Biomaterials 23914 (2002) 2887. [26] C.C. Shih, S.J. Lin, Y.L. Chen, Y.Y. Su, S.T. Lai, G.J. Wu, C.F. Kwok, K.H. Chung, J. Biomed. Mater. Res. 52 (2) (2000) 395. [27] L. Dalmau, H. Alberty, J. Parra, J. Prosthet. Dent. 52 (1984) 116. [28] W.E. Sanford, E. Niboer, in: E. Niboer, J.O. Nriagu (Eds.), Nickel and Human Health Current Perspectives, John Wiley & Sons, Canada, 1992, p. 123. [29] Y. Cheng, C. Wei, K.Y. Gan, L.C. Zhao, Surf. Coat. Technol. 176 (2) (2004) 261. [30] L. Tan, W.C. Crone, Acta Mater. 50 (18) (2002) 4449. [31] R.W.Y. Poon, J.P.Y. Ho, X.Y. Liu, C.Y. Chung, P.K. Chu, K.W.K. Yeung, W.W. Lu, K.M.C. Cheung, Mater. Sci. Eng., A Struct. Mater.: Prop. Microstruct. Process. 390 (1–2) (2004) 444. [32] K.W.K. Yeung, R.W.Y. Poon, X.Y. Liu, J.P.Y. Ho, C.Y. Chung, P.K. Chu, W.W. Lu, D. Chan, K.M.C. Cheung, J. Biomed. Mater. Res. A 72 (3) (2005) 238. [33] R.W.Y. Poon, X.Y. Liu, C.Y. Chung, P.K. Chu, K.W.K. Yeung, W.W. Lu, K.M.C. Cheung, J. Vac. Sci. Technol., A 23 (3) (2005) 525. [34] R.W.Y. Poon, K.W.K. Yeung, X.Y. Liu, P.K. Chu, C.Y. Chung, W.W. Lu, K.M.C. Cheung, D. Chan, Biomaterials 26 (15) (2005) 2265. [35] X.B. Tian, R.K.Y. Fu, L.W. Wang, P.K. Chu, Mater. Sci. Eng., A Struct. Mater.: Prop. Microstruct. Process. 316 (1–2) (2001) 200. [36] M. Long, H.J. Rack, Biomaterials 19 (1998) 1621. [37] P. Sioshansi, E.J. Tobin, Surf. Coat. Technol. 83 (1996) 175. [38] T. Hanawa, Y. Kamiura, S. Yamamoto, T. Kohgo, A. Amemiya, H. Ukai, K. Murakami, K. Asaoka, J. Biomed. Mater. Res. 36 (1997) 131. [39] X.Y. Liu, R.W.Y. Poon, S.C.H. Kwok, P.K. Chu, C.X. Ding, Surf. Coat. Technol. 191 (1) (2005) 43. [40] A. Bolz, M. Schaldach, Artif. Organs 144 (4) (1990) 260. [41] I. Dion, X. Roques, N. More, L. Labrousse, Biomaterials 14 (9) (1993) 712. [42] J.Y. Chen, Y.X. Leng, X.B. Tian, L.P. Wang, N. Huang, P. Yang, P.K. Chu, Biomaterials 23 (12) (2002) 2545. 5606 P.K. Chu / Surface & Coatings Technology 201 (2007) 5601–5606 [43] P.K. Chu, Nucl. Sci. Tech. 15 (3) (2004) 123. [44] A. Thromson, F.G. Law, N. Rushton, J. Franks, Biomaterials 12 (1) (1991) 37. [45] A. Grill, Diamond Relat. Mater. 12 (2) (2003) 166. [46] R. Hauert, Diamond Relat. Mater. 12 (3–7) (2003) 583. [47] J. Robertson, Mater. Sci. Eng., R Rep. 37 (4–6) (2002) 129. [48] M.I. Jones, I.R. McColl, D.M. Grant, K.G. Parker, T.L. Parker, J. Biomed. Mater. Res. 52 (2) (2000) 413. [49] V.S. Veerasamy, G.A.J. Amaratunga, C.A. Davis, A.E. Timbs, W.I. Milne, D.R. Mackenzie, J. Phys., Condens. Matter 5 (1993) 169. [50] S.C.H. Kwok, P. Yang, J. Wang, X.Y. Liu, P.K. Chu, J. Biomed. Mater. Res. A 70 (1) (2004) 107. [51] S.C.H. Kwok, J. Wang, P.K. Chu, Diamond Relat. Mater. 14 (1) (2005) 78.