This is an interactive PDF. Page numbers are linked

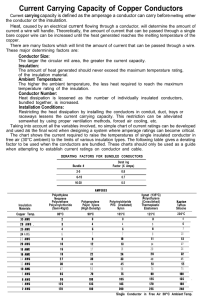

advertisement