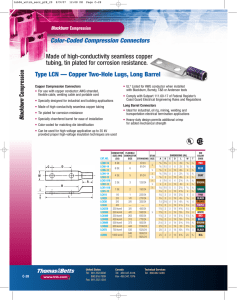

Blackburn Mechanical Connectors Catalogue Blackburn Mechanical

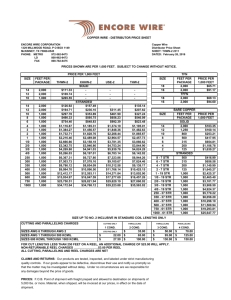

advertisement