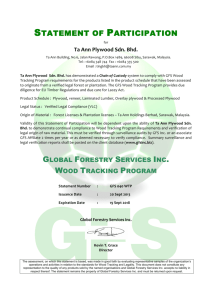

Plywood Design Specification

advertisement