Chiksan Swivel Joints Catalog: Drilling & Production

advertisement

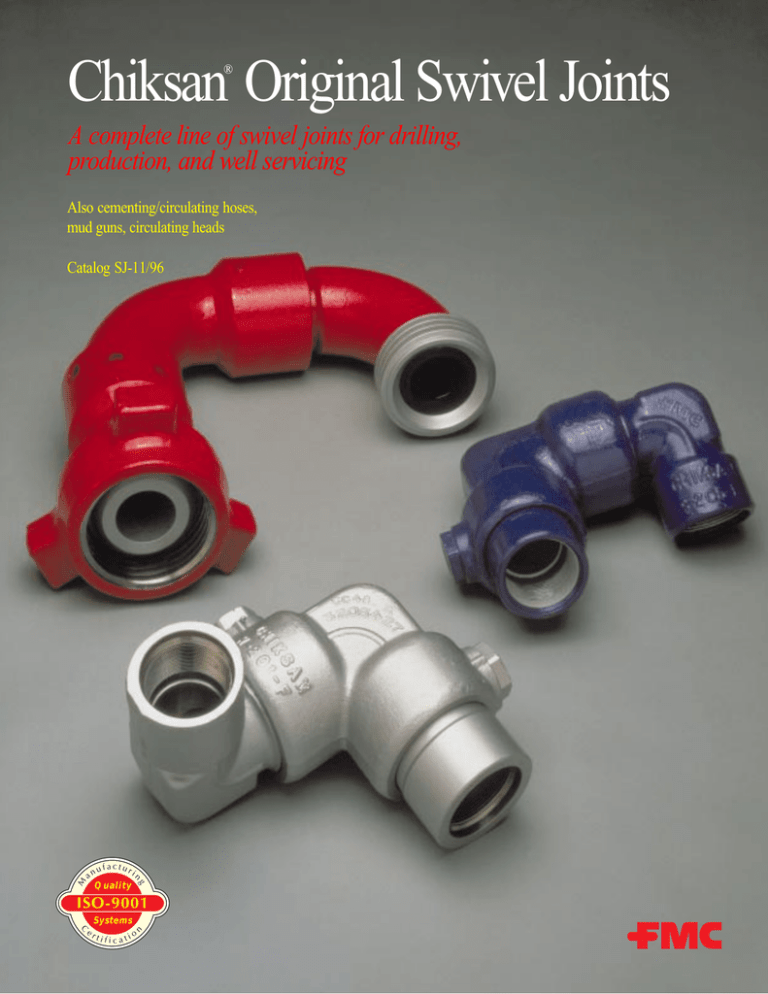

Chiksan Original Swivel Joints ® A complete line of swivel joints for drilling, production, and well servicing Also cementing/circulating hoses, mud guns, circulating heads Catalog SJ-11/96 ufacturi Quality n g M an ISO-9001 C n Systems er tificatio Red Alloy Steel Flanged ends faced and drilled to 150 lb flange specifications unless otherwise noted. Not available in Styles 80 or 10. 3/8- to 4-inch sizes furnished with nitrile packing and brass or stainless steel anti-extrusion ring. 6- to 12-inch sizes furnished with nitrile packing and stainless steel anti-extrusion ring. 2- and 3-inch sizes available in Styles 30 and 40. 6- to 12-inch sizes available in all Styles except Style 20. Furnished with fluoroelastomer packing and stainless steel anti-extrusion ring. FMC does not warrant the performance of any elastomer seal for sour gas service. 7. Power make up must be used for line pipe threaded connections to achieve rated cold working pressure. 8. 5-inch size available with threaded or beveled ends; limited to 3,000 psi cold working pressure. 1. 2. 3. 4. 5. 6. Weco figure 1502 union Alloy Steel 20,000 15,000 Weco figure 2002 union ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ CF CF 6 CF CF 8 CF CF 10 CF CF 12 7 6 6 6 3,7 3,8 6 3,4,5 3 2,3 1,3,4 1,2,3 Notes Sour gas service FMC manufactures Chiksan sour gas swivel joints in accordance with the National Association of Corrosion Engineers (NACE) Standard MR-01-75 and the American Petroleum Institute’s (API) Standard RP-14-E. These swivel joints are specially heat-treated and inspected for controlled hardness. Because the specially heat-treated steel required for sour gas service does not provide a strong enough bearing surface, Chiksan sour gas swivel joints use patented snap-in ball races to assure extra strength and high load-bearing capacity. Elastomeric packing is used to isolate the races and bearings from line fluid. ✓ ✓ ✓ Weco figure 1502 union Alloy Steel 15,000 ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ Weco figure 1502 union ✓ ✓ ✓ ✓ ✓ ✓ ✓ 4 3 ✓ ✓ ✓ ✓ 21⁄2 Weco figure 1002 union Female line pipe threads ✓ Light Blue ✓ ✓ ✓ ✓ CF 2 Sizes, in. ✓ ✓ ✓ 11⁄2 Female line pipe threads ✓ ✓ 11⁄4 ✓ ✓ ✓ 1 Female line pipe threads Red ⁄4 ✓ 3 Alloy Steel 10,000 Black ⁄2 ✓ 1 ✓ 15,000 Olive Green (Sour Gas) Alloy Steel ⁄8 ✓ 3 Weco figure 602 union Beveled for welding NPT NPT Flanged Flanged End Connections Weco figure 2202 union 10,000 Olive Green (Sour Gas) Alloy Steel Carbon Steel Carbon Steel Carbon Steel Carbon Steel Ductile Iron Carbon Steel Ductile Iron Material Alloy Steel 7,500 Olive Green (Sour Gas) 6,000 Silver 10,000 6,000 Olive Green (Sour Gas) Black 1,000 Blue 275 Blue 600 175 Dark Green Dark Green Cold Working Pressure, psi Color Code Notes • All body materials meet ASTM or AISI standards. • Consult factory for special sizes, styles, end connections, or packing units. Longsweep TripleStep Swivel Joints Longsweep® Swivel Joints Extra High-Pressure Swivel Joints High-Pressure Swivel Joints Low-Pressure Swivel Joints Chiksan Models Quick Reference Chart Chiksan Original Swivel Joints Why you should standardize with Chiksan Original Swivel Joints Widest selection in the oilfield Chiksan swivel joints come in 3/8- to 12inch sizes and can handle pressures to 20,000 psi. Sour gas models (see page 6) are limited to 15,000 psi. Eight Chiksan styles or assembly configurations are available from stock. These styles (see page 4) can be combined in an unlimited variety of ways to suit practically any installation. End connections are threaded, integral Weco® wing union, beveled for welding or flanged. Sour gas swivel joints have Weco wing union end connections. Pressure-tight seals protect bearings from line fluid Chiksan swivel joints come standard equipped with nitrile packing and bonded, brass anti-extrusion ring. 6- to 12-inch sizes have stainless steel anti-extrusion ring. The anti-extrusion ring serves as a retainer and bearing to reduce friction between the resilient packing material and the packing chamber as the joint is turned. These dynamic-seal packing units protect ball races and bearings from line fluid through the stated pressure range, including vacuum or suction service, to 225˚F. Longsweep® TripleStep models have a secondary O-ring seal which prevents minor leakage past the primary seal from contacting the bearings. These swivel joints also have a leak detection port between the packing and O-ring seal. If leakage past the packing should occur, it is forced through the leakdetection port, signalling the need for packing replacement. Bearings key to rotation, strength To assure long, dependable operation, Chiksan ball bearings are matched to loading and service conditions. Although the size, type, and number of bearings vary, Chiksan low-pressure, high-pressure, and extra highpressure swivel joints all have two rows of bearings in each swivel and flame-hardened ball races. Longsweep and Longsweep TripleStep swivel joints have three rows of bearings in each swivel for improved load capacities. All Longsweep and Longsweep TripleStep swivel joints for standard service have carburized and hardened ball races. Smooth, round bore minimizes flow restrictions Chiksan swivel joints have smooth, round bores to minimize turbulence and keep pressure drop low. Longsweep and Longsweep TripleStep swivel joints have extra-long radius elbows for even better flow characteristics and reduced chance of washout when handling abrasives at extremely high pressures. Simple maintenance Only occasional light greasing with a small, hand-held grease gun is required to keep Chiksan swivel joints on the job. If packing, bearings, or ball plugs should need replacing because of leakage, field repair kits are available. Easy-to-follow instructions come with each repair kit. Table of Contents Chiksan Swivel Joints Low-Pressure Swivel Joints ...................................... High-Pressure Swivel Joints ..................................... Extra High-Pressure Swivel Joints ........................... Longsweep Swivel Joints .......................................... Longsweep TripleStep Swivel Joints ........................ Chiksan Styles and Component Parts Low- and High-Pressure Swivel Joints ..................... Extra High-Pressure and Longsweep Swivel Joints . Sour Gas Service .............................................................. Lubricants ......................................................................... Chiksan Swivel Joint Specificaions Low-Pressure Swivel Joints ...................................... High-Pressure Swivel Joints ..................................... Extra High-Pressure Swivel Joints ........................... Longsweep Swivel Joints .......................................... Longsweep TripleStep Swivel Joints ........................ Chiksan Cementing and Circulating Hoses ..................... Chiksan Mud Mixing Guns .............................................. Chiksan Circulating Heads ............................................... How to Order .................................................................... Warnings and Safety Instructions .................................... 2 2 2 3 3 4 5 6 6 1 7 8 8 9 9 10 11 12 12 13 Chiksan Original Swivel Joints Low-Pressure Swivel Joints 175 psi (12 bar) to 1,000 psi (70 bar) cold working pressure; 3/4- to 12-inch sizes Recommended service Transfer lines, temporary flow lines, discharge lines, auxiliary flow lines, water lines, and other general-service oilfield applications High-Pressure and Extra High-Pressure Swivel Joints Low-Pressure Swivel Joint, Style 50 6,000 psi (414 bar) cold working pressure; 3/8- to 4-inch sizes 10,000 psi (690 bar) cold working pressure; 2-inch size Recommended service Hydraulic control lines, mud lines, rotary line connections, BOP lines, test lines, water lines, offshore wellhead connections, cementing and circulating hoses, and chokeand-kill lines NOTE: Available for sour gas service at 6,000 psi (414 bar) cold working pressure; integral Weco wing union end connections; consult factory for other end connections, dimensions, and weights. High-Pressure Swivel Joint, Style 50 Longsweep Swivel Joints 7,500 psi (517 bar), 10,000 psi (690 bar), 15,000 psi (1034 bar), and 20,000 psi (1380 bar) cold working pressure; 1- to 4-inch sizes Recommended service Long-radius elbows designed especially for high-pressure sour gas abrasive applications such as fracturing, choke-and-kill lines, cementing and circulating hoses, acidizing, and test lines Longsweep Swivel Joint, Style 50 NOTE: Available for sour gas service at 7,500 psi (517 bar), 10,000 psi (690 bar), and 15,000 psi (1034 bar) cold working pressure; 1, 2, 3, and 4-inch sizes; integral Weco wing union end connections only. See Specifications Table (pages 7, 8, and 9) for styles, sizes, end connections, dimensions, and weights. 2 Chiksan Original Swivel Joints Longsweep TripleStep Swivel Joints 15,000 psi (1034 bar) cold working pressure; 3-inch size Patented seal meets all applications from vacuum to 20,000 psi, -50°F to 300°F Added erosion allowance under ball races with no increase in size or weight Teflon seal lasts up to five times longer than elastomer seals Recommended service Long-radius elbows designed especially for highpressure abrasive applications such as fracturing, choke-and-kill lines, cementing and circulating hoses, acidizing, and test lines Features & Benefits “Stepped” ball race design: A patent pending “stepped” ball race design significantly increases bending and axial load capacities for greater strength, safety, and life. Additionally, the stepped design adds considerable wall thickness under the male ball races to increase erosion allowance. Patented Teflon seal: FMC’s world proven Straight-Bore Teflon* Seal (SBTS) provides unsurpassed sealability and lasts up to five times longer than elastomer seals. The SBTS is compatible with all known oilfield fluids from vacuum to 20,000 psi, -50°F to 300°F (-46°C to 149°C) and is impervious to chemical attack and explosive gas decompression. New alloy steel provides superior hardness Positive back-up seal protects ball races against operating environments Environmental seal and high-performance grease eliminate routine greasing Advanced material selection: The TripleStep swivel joint is manufactured from forged alloy steel with a closely controlled, proprietary chemical composition and heat treatment to assure superior toughness, ductility, case depth, case hardness, and core strength with no increase in size or weight. Longsweeep TripleStep Swivel Joint Eliminates routine maintenance: An improved environmental seal reduces the potential for corrosion in the ball race area. The integrity of the seal and the use of a high-performance grease during initial assembly eliminates the need for periodic greasing. See Specifications Table (page 9) for styles, sizes, end connections, dimensions, and weights. 3 Chiksan Styles and Component Parts C hiksan swivel joints are available from stock in eight basic styles or configurations. These styles permit 360-degree rotation and movement in one, two, or three planes. They can be combined in an unlimited variety of ways to suit practically any installation. All Chiksan swivel joints are assembled using two or more standard pieces. Component piece numbers are shown here with the various Chiksan swivel joint styles. NOTE: Although Chiksan swivel joints can be rotated while under fluid pressure, they are not recommended for services requiring continuous rotary motion. Low-Pressure and High-Pressure Swivel Joints No. 3 pc. No. 6 pc. No. 4 pc. No. 3 pc. No. 4 pc. Style 20 Single swivel coupling No. 1 pc. No. 5 pc. Style 40 Single swivel with two elbows Style 30 Single swivel with one elbow No. 1 pc. No. 1 pc. No. 3 pc. No. 5 pc. No. 5 pc. No. 3 pc. Style 50 Two swivels with two elbows No. 1 pc. No. 3 pc. Style 60 Two swivels with one elbow No. 2 pc. No. 1 pc. No. 5 pc. Style 70 Two swivels with three elbows No. 2 pc. No. 3 pc. No. 3 pc. No. 5 pc. No. 3 pc. Style 80 Three swivels with three elbows Style 10 Three swivels with two elbows 4 Chiksan Styles and Component Parts Extra High-Pressure Swivel Joints No. 4 pc. No. 4 pc. No. 5 pc. No. 2 pc. No. 3 pc. No. 6 pc. No. 3 pc. Style 20 Single swivel coupling No. 3 pc. No. 4 pc. Style 30 Single swivel with one elbow Style 40 Single swivel with two elbows Style 50 Two swivels with two elbows No. 6 pc. No. 3 pc. No. 2 pc. No. 4 pc. No. 2 pc. No. 2 pc. No. 2 pc. No. 3 pc. No. 3 pc. No. 4 pc. No. 6 pc. No. 2 pc. No. 5 pc. Style 60 Two swivels with one elbow Style 70 Two swivels with three elbows No. 2 pc. Style 80 Three swivels with three elbows Style 10 Three swivels with two elbows Longsweep and TripleStep Swivel Joints No. 4 pc. No. 5 pc. No. 4 pc. No. 4 pc. No. 2 pc. No. 2 pc. No. 6 pc. No. 3 pc. No. 3 pc. No. 3 pc. Style 30 Single swivel with one elbow No. 4 pc. Style 40 Single swivel with two elbows No. 2 pc. Style 50 Two swivels with two elbows No. 2 pc. No. 2 pc. No. 5 pc. No. 2 pc. No. 2 pc. No. 5 pc. No. 6 pc. No. 6 pc. Style 70 Two swivels with three elbows Style 60 Two swivels with one elbow Style 80 Three swivels with three elbows 5 No. 3 pc. Style 10 Three swivels with two elbows Sour Gas Service FMC manufactures Chiksan sour gas swivel joints in accordance with the National Association of Corrosion Engineers (NACE) Standard MR-01-75 and the American Petroleum Institute’s (API) Standard RP-14-E. These swivel joints are specially heat-treated and inspected for controlled hardness. Because the specially heat-treated steel required for sour gas does not provide a hard enough bearing surface, Chiksan sour gas swivel joints use snap-in ball races (shown at right) for extra strength and high load-bearing capacity. Elastomeric packing with stainless steel anti-extrusion ring and secondary O-ring seal are used to isolate the races and bearings from line fluid. Sour gas swivel joints also have a leakdetection port between the packing and the O-ring seal. If leakage past the packing should occur, it is forced through the port, signalling the need for packing replacement. For positive identification, all Chiksan sour gas swivel joints are stamped “Sour Gas” using low-stress dot stamping and painted with an olive green, zinc-chromate primer that’s unique to sour gas equipment. Female snap-in races Fluoroelastomer packing Male snap-in races Secondary O-ring seal Chiksan Longsweep sour-gas swivel joint Lubricants for Chiksan Swivel Joints L ubricants for Chiksan swivel joints are formulated for year-round use in harsh, often severe oilfield applications. Only occasional light greasing with a small, hand-held grease gun is required to keep Chiksan swivel joints on the job. NOTE: Excessive lubrication can cause swivel to bind, distort the anti-extrusion ring, displace the packing, and expose the bearing cavities to line pressure. Use only enough lubricant to obtain smooth rotation. High-temperature lubricant • Noncorrosive grease for high-temperature services • Maintains stability at temperatures ranging from 0˚F to 400˚F • Available in 2-, 5-, 7 1/2 -, 25-, and 50-pound cans Standard lubricant • Petroleum-base grease without synthetic or mineral fillers • Assures continual lubrication of bearings at temperatures of -50˚F to 212˚F • Available in 14 1/2-ounce cartridge for use with grease gun; also comes in 2-, 5-, 7 1/2-, 25-, and 50-pound cans 6 Leak-detection port 7 33⁄4 1013⁄16 20 95 275 9.1 23⁄16 56 B 3 76 21⁄2 64 23⁄8 60 4 102 41⁄4 108 91⁄4 27 45⁄8 235 12.1 117 53⁄4 146 41⁄2 114 16 7.3 71⁄2 3.4 43⁄4 2.2 A 31⁄2 89 3 76 21⁄2 64 91⁄4 235 18 8.2 53⁄4 146 16 7.3 31⁄2 89 20 9.1 91⁄2 4.3 A 31⁄2 89 3 76 21⁄2 64 95⁄8 244 20 9.1 31⁄2 89 A 3 7⁄ 8 98 93⁄8 121⁄2 41⁄4 211 6.7 108 7 1⁄ 4 3.3 95⁄8 117⁄8 25 61⁄8 244 302 11.4 156 71⁄4 184 F 77⁄8 200 95⁄8 117⁄8 25 61⁄8 244 302 11.4 156 B C 41⁄8 105 91⁄2 241 8 203 D 11 5.0 7 3.2 1 7 15 1 7 7 15 15 5 7 15 15 8 8 203 203 16 75 406 34.1 75⁄8 75⁄8 151⁄4 53 194 194 387 24.1 Beveled – – 19 193⁄4 330 483 502 150 – – Flanged 157⁄8 103⁄4 170 123⁄4 12 223⁄4 238 123⁄2 343⁄4 24 382 12 343⁄4 223⁄4 343⁄4 500 223⁄4 223⁄4 420 12 343⁄4 463⁄4 580 12 343⁄4 343⁄4 223⁄4 463⁄4 571⁄2 750 343⁄4 223⁄4 223⁄4 451⁄2 670 403 273 77.3 324 305 578 108.2 324 883 610 173.6 305 883 578 883 227.3 578 578 190.9 305 883 1187 263.6 305 883 883 578 1187 1461 340.9 883 578 578 1156 304.6 19 161⁄2 271⁄4 410 19 343⁄4 33 474 161⁄2 343⁄4 271⁄4 433⁄4 665 271⁄4 271⁄4 590 161⁄2 343⁄4 511⁄4 740 161⁄2 343⁄4 343⁄4 271⁄4 511⁄4 62 910 343⁄4 271⁄4 271⁄4 541⁄2 840 483 419 692 186.4 483 883 838 215.5 419 883 692 1111 302.3 692 692 268.2 419 883 1302 336.4 419 883 883 692 1302 1575 413.6 883 692 692 1384 381.8 135⁄16 93⁄4 120 103⁄4 10 193⁄4 157 103⁄4 293⁄4 20 213 10 293⁄4 193⁄4 293⁄4 346 193⁄4 193⁄4 293 10 293⁄4 393⁄4 402 10 293⁄4 293⁄4 193⁄4 393⁄4 491⁄2 519 293⁄4 193⁄4 193⁄4 391⁄2 466 338 248 54.6 273 254 502 71.4 273 756 508 96.8 254 756 502 756 157.3 502 502 133.2 254 756 1010 182.7 254 756 756 502 1010 1257 235.9 756 502 502 1003 211.8 – – Beveled 14 293⁄4 293⁄4 233⁄4 433⁄4 531⁄2 631 293⁄4 233⁄4 233⁄4 471⁄2 578 356 756 756 603 1111 1059 286.8 756 603 603 1207 262.7 14 233⁄4 269 16 293⁄4 28 317 14 293⁄4 233⁄4 373⁄4 458 233⁄4 233⁄4 405 14 293⁄4 433⁄4 506 356 603 122.3 406 756 711 144.1 356 756 603 959 208.2 603 603 184.1 356 756 1111 230 15 8 151⁄4 171⁄8 85 91⁄8 203 387 435 38.6 232 75⁄8 141⁄8 163⁄4 58 91⁄8 194 359 425 26.4 232 16 173⁄4 224 16 406 451 101.8 406 15 91⁄8 232 91⁄8 232 – – 7 91⁄8 232 91⁄8 232 Flanged 15 91⁄8 151⁄4 74 61⁄8 232 387 33.6 156 91⁄8 141⁄8 45 5 232 359 20.5 127 8 151⁄4 94 85⁄8 231⁄4 16 123 8 231⁄4 151⁄4 231⁄4 186 151⁄4 151⁄4 156 8 231⁄4 311⁄4 216 8 231⁄4 231⁄4 151⁄4 311⁄4 381⁄2 279 231⁄4 151⁄4 151⁄4 301⁄2 249 203 387 42.7 219 591 406 55.9 203 591 387 591 84.6 387 387 70.9 203 591 794 98.2 203 591 591 387 794 978 126.8 591 387 387 775 113.2 7 8 56 61⁄8 203 25.5 156 75⁄8 35 5 194 15.9 127 111⁄2 71⁄4 63 85⁄8 292 184 28.6 219 1 8 141⁄8 65 8 203 359 29.6 203 75⁄8 125⁄8 40 75⁄8 194 321 18.2 194 – – 7 91⁄8 232 91⁄8 232 Beveled 15 91⁄4 121⁄4 57 61⁄8 235 311 25.9 156 10 5 29 254 13.2 127 131⁄2 151⁄4 141 131⁄2 12 191⁄4 174 131⁄2 231⁄4 24 199 12 231⁄4 191⁄4 311⁄4 273 193⁄4 193⁄4 234 12 231⁄4 351⁄4 303 12 231⁄4 231⁄4 191⁄4 351⁄4 421⁄2 360 231⁄4 191⁄4 191⁄4 381⁄2 336 343 387 64.1 343 305 489 79.9 343 591 610 90.5 305 591 489 794 124.1 502 502 106.4 305 591 895 137.7 305 591 591 498 895 1050 163.6 591 489 489 978 152.7 1 81⁄8 47 9 206 21.4 229 73⁄4 24 51⁄32 91⁄4 197 10.9 128 235 – – 7 61⁄8 156 51⁄32 5 128 127 Flanged 17 7.7 71⁄2 39 9 191 17.7 229 71⁄4 184 6 127⁄16 58 65⁄8 187⁄16 12 6 187⁄16 127⁄16 187⁄16 123 127⁄16 127⁄16 108 73 6 187⁄16 247⁄16 137 6 187⁄16 187⁄16 127⁄16 247⁄16 307⁄8 185 187⁄16 127⁄16 127⁄16 247⁄8 170 152 316 26.4 168 468 305 33.2 152 468 316 468 55.9 316 316 49.1 152 468 621 62.3 152 468 468 316 621 784 84.1 468 316 316 632 77.3 67⁄8 67⁄8 133⁄4 35 175 175 349 15.9 67⁄8 67⁄8 133⁄4 491⁄2 175 175 349 22.5 67⁄8 67⁄8 133⁄4 35 175 175 349 15.9 67⁄8 67⁄8 133⁄4 461⁄2 175 175 349 21.1 67⁄8 67⁄8 133⁄4 39 175 175 349 17.7 53⁄4 53⁄4 111⁄2 23 146 146 292 10.5 65⁄16 65⁄16 125⁄8 41 160 160 321 18.6 53⁄4 53⁄4 111⁄2 23 146 146 292 10.5 41⁄2 5 114 127 37⁄8 98 97⁄16 67⁄16 46 65⁄8 240 164 20.9 168 67⁄8 121⁄4 141⁄2 40 75⁄8 175 311 368 18.2 194 67⁄8 131⁄8 141⁄2 56 75⁄8 175 333 368 25.5 194 67⁄8 121⁄4 141⁄2 40 75⁄8 175 311 368 18.2 194 67⁄8 131⁄8 141⁄2 54 75⁄8 175 333 368 24.6 194 67⁄8 121⁄4 141⁄2 42 75⁄8 175 311 368 19.1 194 53⁄4 146 61⁄4 103⁄8 127⁄16 41 61⁄8 159 264 316 18.6 156 53⁄4 146 41⁄2 114 E 63⁄8 162 – – 75⁄8 194 75⁄8 194 75⁄8 194 75⁄8 194 75⁄8 194 61⁄8 156 61⁄8 156 61⁄8 156 47⁄8 124 D 37⁄8 98 Beveled 75⁄8 194 75⁄8 194 75⁄8 194 75⁄8 194 75⁄8 194 61⁄8 156 61⁄8 156 61⁄8 156 41⁄4 108 4 102 C Wt. (lb) (kg) 9 ⁄2 15 ⁄16 107 11 18 ⁄16 19 119 9 ⁄2 18 ⁄16 15 ⁄16 25 ⁄16 177 15 ⁄16 15 ⁄16 162 9 ⁄2 18 ⁄16 27 ⁄16 185 9 ⁄2 18 ⁄16 18 ⁄16 15 ⁄16 27 ⁄16 34 ⁄8 239 18 ⁄16 15 ⁄16 15 ⁄16 317⁄8 224 241 405 48.6 279 468 483 54.1 241 468 405 646 80.5 405 405 73.6 241 468 710 84.1 241 468 468 405 710 873 108.6 468 405 405 810 101.8 75⁄8 121⁄4 32 45⁄8 194 311 14.5 117 75⁄8 131⁄8 51 51⁄2 194 333 23.2 140 75⁄8 121⁄4 32 45⁄8 194 311 14.5 117 75⁄8 131⁄8 48 51⁄2 194 333 21.8 140 75⁄8 121⁄4 35 45⁄8 194 311 15.9 117 61⁄8 156 B 37⁄8 98 B Style 10 D 11 13 ⁄16 94 11 279 341 42.7 279 67⁄8 24 45⁄8 175 10.9 117 67⁄8 38 51⁄2 175 17.3 140 67⁄8 24 45⁄8 175 10.9 117 67⁄8 36 51⁄2 175 16.4 140 67⁄8 27 45⁄8 175 12.3 117 53⁄4 146 95⁄8 244 71⁄4 184 51⁄4 2.4 61⁄8 103⁄8 38 41⁄4 156 264 17.3 108 61⁄8 156 41⁄4 108 C 61⁄8 156 Wt. (lb) (kg) C – – 67⁄8 111⁄2 28 67⁄8 175 292 12.7 175 67⁄8 123⁄8 45 67⁄8 175 314 20.5 175 67⁄8 111⁄2 28 67⁄8 175 292 12.7 175 67⁄8 123⁄8 42 67⁄8 175 314 19.1 175 67⁄8 111⁄2 31 67⁄8 175 292 14.1 175 53⁄4 146 B 35⁄8 92 Wt. (lb) (kg) D F Style 80 C A Flanged 75⁄8 194 75⁄8 194 75⁄8 194 53⁄4 146 41⁄2 114 B 37⁄8 98 B Style 70 C E 9 229 91⁄4 24 45⁄8 235 10.9 117 11 40 51⁄2 279 18.2 140 91⁄4 24 45⁄8 235 10.9 117 18 8.2 81⁄2 3.9 A 37⁄8 98 Wt. (lb) (kg) 55⁄16 99⁄16 36 65⁄16 65⁄16 26 41⁄4 160 268 16.4 160 160 11.8 108 91⁄4 235 71⁄2 191 5 2.3 Style 60 A B 35⁄8 92 75⁄8 194 75⁄8 194 75⁄8 194 75⁄8 194 75⁄8 194 61⁄8 156 61⁄8 156 53⁄4 146 41⁄2 114 D 63⁄8 162 Wt. (lb) (kg) B A Flanged 4 102 21 9.6 7 121⁄2 31⁄2 178 5.7 89 81⁄2 216 61⁄8 156 41⁄4 108 37⁄8 98 C Style 50 B A A 61⁄8 156 20 9.1 3 76 B 35⁄8 92 C C 35⁄8 92 67⁄8 175 67⁄8 33 71⁄2 175 15.0 191 20 9.1 A 21⁄2 64 75⁄8 107⁄8 35 51⁄2 194 276 15.9 140 75⁄8 194 61⁄8 156 61⁄8 156 61⁄2 3.0 31⁄2 1.6 7 121⁄2 31⁄2 178 5.7 89 6 152 5 127 C Wt. (lb) (kg) D B Threaded 45⁄8 117 51⁄2 140 10 4.6 6 152 67⁄8 29 7 175 13.2 178 67⁄8 175 B 35⁄8 92 23⁄16 41⁄4 56 108 67⁄8 23 4 175 10.5 102 53⁄4 146 21 9.6 B Style 40 10 215⁄16 61⁄8 4.6 75 156 61⁄2 3.0 15⁄8 41 A C A 33⁄32 415⁄16 65⁄8 121⁄2 4 78 125 168 5.7 102 65⁄8 27 71⁄2 168 12.8 191 53⁄4 146 41⁄2 114 31⁄2 1.6 Wt. (lb) (kg) C A Beveled 33⁄32 71⁄2 78 191 45⁄8 117 45⁄8 117 31⁄2 89 3 15 5 1 Threaded 3 ⁄32 4 ⁄16 6 ⁄8 12 ⁄4 4 78 125 168 5.6 102 Flanged C 37⁄8 98 41⁄4 65⁄16 108 160 51⁄2 140 4 102 23⁄8 60 6 152 65⁄8 25 7 168 11.4 178 Flanged 33⁄32 7 78 178 16 7.3 3 15 5 Threaded 3 ⁄32 4 ⁄16 6 ⁄8 78 125 168 33⁄4 95 A 15⁄8 41 Style 30 A 71⁄2 215⁄16 31⁄2 3.4 75 89 41⁄2 2.1 71⁄2 3.4 25⁄8 67 25⁄8 67 53⁄4 146 5 127 21⁄2 1.1 Wt. (lb) (kg) 53⁄4 146 Beveled Flanged C 41⁄2 114 C B • All weights for steel swivel joints; malleable iron joints weigh approximately 10% less; consult factory for exact weights, joints. • Standard threads for low-pressure swivel joints are NPT. • Outside diameter of ANSI 150 flange; faced and drilled to ANSI 150 specifications. Notes 305 12 254 10 203 8 152 6 102 4 76 3 64 21⁄2 51 2 33⁄4 95 25⁄8 67 Threaded 27⁄8 73 B 21⁄4 57 1 Threaded 2 ⁄16 52 A 13⁄4 44 11⁄4 – 11⁄2 32 – 38 3 Threaded End Connections Style 20 ⁄4 – 1 19 – 25 Sizes (inches) (mm) A B Low-pressure swivel joints Chiksan Swivel Joint Specifications 15 1 1 Threaded 2 ⁄16 4 ⁄2 8 ⁄4 75 114 210 21⁄2 65 33⁄16 423⁄32 5 81 120 2.2 33⁄4 1.7 37⁄8 98 C A B D 8 B C Wt. (lb) (kg) A B C C D D Style 80 F E F E Wt. (lb) (kg) 45⁄8 45⁄8 117 117 C 47⁄32 45⁄8 107 117 45⁄8 91⁄4 117 235 51⁄16 150 D 9 4.0 4 1.8 Wt. (lb) (kg) 41⁄32 57⁄8 929⁄32 31 41⁄32 6 61⁄2 527⁄32 101⁄32 1211⁄32 38 6 527⁄32 615⁄32 125⁄16 33 102 149 252 14.0 102 152 165 148 255 314 17.1 152 148 164 313 15.0 33⁄16 49⁄32 715⁄32 93⁄8 33⁄16 49⁄32 427⁄32 423⁄32 715⁄32 99⁄16 111⁄2 49⁄32 423⁄32 55⁄16 101⁄32 10 81 109 190 4.2 81 109 123 120 190 243 5.2 109 120 135 255 4.5 53⁄4 223⁄32 47⁄32 615⁄16 8 223⁄32 47⁄32 47⁄32 45⁄8 615⁄16 821⁄32 10 2.6 69 107 176 3.6 69 107 107 117 176 225 4.5 B B Style 10 D 27⁄8 213⁄16 31⁄8 73 71 79 A C A C 41⁄8 67⁄16 105 164 B Style 30 A B 21 9.5 Wt. (lb) (kg) C 31⁄4 83 A C C Wt. (lb) (kg) A B C Style 50 B D C A Wt. (lb) (kg) D A A B Style 60 B Wt. (lb) (kg) A 65⁄16 81⁄4 28 41⁄8 67⁄16 71⁄2 115⁄8 36 71⁄2 631⁄32 29 41⁄8 160 210 12.7 105 164 190 295 16.3 190 177 13.1 105 B Style 40 B A • Where dimensions are critical, consult factory. • Standard joints have female line pipe threads. Male threads available on special order; beveled for weld, consult factory C A B 31⁄4 83 A 211⁄16 43⁄8 631⁄32 14 Threaded 68 111 177 6.3 C Wt. (lb) (kg) Style 20 A B Extra high-pressure swivel joints A B C Wt. (lb) (kg) C A 73⁄8 111⁄2 44 41⁄8 187 292 20.0 105 B Style 70 C A B C D D Style 80 F E F E Wt. (lb) (kg) A 71⁄2 67⁄16 71⁄2 115⁄8 1331⁄32 54 71⁄2 190 164 190 295 355 24.4 190 B C B A B C Style 10 D D Wt. (lb) (kg) 71⁄2 631⁄32 141⁄2 47 190 177 368 21.3 B C A 97⁄8 157⁄16 86 97⁄8 97⁄8 73 59⁄16 95⁄8 153⁄16 101 59⁄16 103⁄16 109⁄16 97⁄8 153⁄4 207⁄16 123 103⁄16 97⁄8 1013⁄16 2011⁄16 110 251 392 39.0 251 251 33.0 141 244 386 45.4 141 259 268 251 400 519 55.3 259 251 275 525 50.0 • Where dimensions are critical, consult factory. • Consult factory for sour gas swivel joint dimensions. • Standard joints have female line pipe threads. Male threads available on special order; beveled for weld, consult factory Notes B Style 70 C B 45⁄8 97⁄16 32 45⁄16 83⁄4 91⁄4 38 45⁄8 715⁄16 85⁄8 131⁄4 53 85⁄8 85⁄8 48 45⁄8 715⁄16 129⁄16 59 45⁄8 715⁄16 83⁄4 85⁄8 129⁄16 173⁄8 77 715⁄16 85⁄8 97⁄16 181⁄16 71 117 240 14.4 110 222 235 17.1 117 202 219 337 24.0 219 219 21.6 117 202 319 26.6 117 202 222 219 319 441 35.0 202 219 240 459 32.0 13 ⁄`16 71⁄16 95⁄8 38 51⁄4 59⁄16 1013⁄16 51 51⁄2 109⁄16 111⁄8 64 59⁄16 95⁄8 Threaded 4122 179 244 17.1 133 141 275 23.0 140 268 283 29.0 141 244 2 50 A A C A 31⁄8 513⁄16 91⁄8 25 41⁄2 86 148 232 11.3 114 4 100 End Connections B Wt. (lb) (kg) 61⁄4 33⁄16 49⁄32 423⁄32 729⁄32 8 423⁄32 423⁄32 7 2.8 81 109 120 201 3.6 120 120 3.1 Threaded Sizes (inches) (mm) A Style 60 B A B 31⁄4 213⁄16 213⁄16 23⁄4 115⁄16 27⁄8 413⁄16 33⁄4 115⁄16 27⁄8 35⁄32 213⁄16 413⁄16 531⁄32 43⁄4 1.5 71 71 1.2 49 73 122 1.7 49 73 80 71 122 152 2.1 Wt. (lb) (kg) A 57⁄8 81⁄16 191⁄2 41⁄32 57⁄8 527⁄32 97⁄8 27 527⁄32 527⁄32 20 149 205 8.8 102 149 148 251 12.8 148 148 9.0 49⁄32 63⁄8 109 162 3 80 Notes C Style 50 B 21⁄2 115⁄16 27⁄8 213⁄16 43⁄4 1.1 49 73 71 120 Wt. (lb) (kg) C 47⁄32 57⁄16 41⁄2 223⁄32 47⁄32 45⁄8 711⁄32 63⁄4 107 138 2.0 69 107 117 187 3.0 21⁄8 73 B Style 40 B D A 47⁄8 71⁄8 22 4 711⁄16 93⁄4 29 47⁄8 711⁄16 71⁄8 12 37 71⁄8 71⁄8 33 47⁄8 711⁄16 129⁄16 45 47⁄8 711⁄16 711⁄16 71⁄8 129⁄16 1413⁄16 53 711⁄16 71⁄8 813⁄16 1515⁄16 48 124 181 10.0 102 195 248 13.0 124 195 181 305 16.7 181 181 15.0 124 195 319 20.2 124 195 195 181 319 376 24.0 195 181 224 405 21.6 31⁄8 79 21⁄2 64 13⁄4 44 11⁄4 32 A C A 33⁄4 95 18 8.1 41⁄8 621⁄32 101⁄2 33⁄16 41⁄32 527⁄32 15 105 169 4.7 81 102 148 6.8 23⁄8 60 13⁄4 223⁄32 45⁄8 44 69 117 21⁄4 57 Threaded C 27⁄8 515⁄32 4 73 139 1.8 2 50 B Wt. (lb) (kg) C 11⁄4 115⁄16 213⁄16 13⁄4 32 49 71 .8 A Style 30 A B 21⁄8 54 Threaded 27⁄16 53⁄16 23⁄4 62 132 1.2 11⁄4 – 11⁄2 32 – 40 17⁄8 48 Threaded 3 ⁄4 – 1 20 – 25 C 3 27 5 1 Threaded 1 ⁄16 1 ⁄32 3 ⁄16 1 ⁄2 30 47 84 .7 B 3 ⁄8 – 1⁄2 10 – 15 A Wt. (lb) (kg) End Connections C Sizes (inches) (mm) Style 20 A B High-pressure swivel joints Chiksan Swivel Joint Specifications 9 9 229 7 ⁄8 200 Weco Wing Union (MxM) Weco Wing Union (MxF) Weco Wing Union (MxM) 9 ⁄8 238 3 73⁄8 187 NA NA 5 ⁄8 143 5 NA NA 43⁄8 111 C NA 63⁄8 1011⁄16 63⁄8 162 271 162 5 ⁄8 143 5 43⁄8 111 B NA NA 71⁄4 184 70 31.5 NA NA NA NA 51⁄4 49 93⁄8 163⁄8 93⁄8 133 22.0 238 416 238 33 14.9 21 9.5 12 5.4 8 3.6 A Style 40 93⁄8 127⁄8 41⁄8 238 327 105 41⁄8 105 3 76 23⁄8 41 D A NA 3 76 NA NA 2 ⁄8 60 3 NA NA 13⁄4 44 C Wt. (lb) (kg) CD B NA 51⁄2 107⁄8 140 276 63⁄8 162 5 ⁄8 143 7 71⁄8 181 43⁄8 111 5 B A B Style 30 Weco Wing Union 715⁄16 141⁄2 (MxF) 202 368 Threaded Weco Wing Union (MxM) Weco Wing Union (MxF) Threaded Weco Wing Union (MxM) Weco Wing Union (MxF) Threaded Weco Wing Union (MxM) Weco Wing Union (MxF) Threaded End Connections D 3 NA 22 10 NA 3 76 2 ⁄8 60 3 13⁄4 44 A B NA C 9 229 107⁄8 107⁄8 276 276 16 7.2 11 4.9 Wt. (lb) (kg) B B B 3 5 ⁄8 9 ⁄8 143 238 5 43⁄8 73⁄8 111 187 A A E 5 NA NA 5 ⁄8 143 NA 9 ⁄8 238 3 D E D Wt. (lb) (kg) C 71⁄8 181 A A 27 15 8 381 12.2 203 43⁄8 113⁄4 16 111 298 7.2 NA 73⁄8 187 C Style 70 B A 9 ⁄8 238 3 73⁄8 187 B E E 5 NA NA 5 ⁄8 143 NA 9 ⁄8 238 3 D E D D 19 8.6 Wt. (lb) (kg) C C B B 3 17 7.7 Wt. (lb) (kg) C C C 83⁄8 23 213 10.4 101⁄8 93⁄8 101⁄8 45 257 238 257 20.3 101⁄8 93⁄8 101⁄8 39 257 238 257 17.6 26 8 203 11.7 NA 83⁄8 77⁄8 213 187 71⁄8 181 C Style 10 B B 71⁄8 77⁄8 181 187 A A A A 31 8 15 9 ⁄8 381 13.9 203 238 43⁄8 113⁄4 111 298 NA 73⁄8 187 C Style 80 B B 53 23.8 44 19.8 NA NA NA 107⁄8 1011⁄16 107⁄8 70 276 271 276 31.5 107⁄8 101⁄4 101⁄4 51⁄2 161⁄8 66 107⁄8 1011⁄16 107⁄8 61 276 256 256 140 409 29.7 276 271 276 27.4 9 9 1011⁄16 1011⁄16 63⁄8 171⁄16 52 45 9 1011⁄16 9 29 63⁄8 1011⁄16 1011⁄16 63⁄8 171⁄16 44 229 13.0 162 271 271 162 433 20.0 229 271 271 162 433 23.4 229 271 229 20.4 NA NA 8 203 NA 8 203 C 71⁄8 181 NA 71⁄8 181 B Style 60 A 51⁄2 1011⁄16 107⁄8 49 107⁄8 107⁄8 140 271 276 22.0 276 276 37 16.7 5 93⁄8 101⁄8 34 127 238 257 15.3 5 ⁄8 9 ⁄8 8 143 238 203 5 19 8.6 73⁄8 83⁄8 187 213 37⁄8 98 C 14 6.4 B Wt. (lb) (kg) C 43⁄8 73⁄8 71⁄8 111 187 181 A Style 50 28 63⁄8 1011⁄16 9 12.6 162 271 229 17 7.7 10 4.5 Wt. (lb) (kg) A B C A A NA 911⁄16 213⁄16 203⁄8 271 246 538 518 122 NA NA NA 141⁄2 141⁄2 368 368 715⁄16 163⁄8 141⁄2 101 141⁄2 141⁄2 202 416 368 45.5 368 368 103 46.6 90 40.5 NA NA NA NA NA NA NA 203⁄8 213⁄16 203⁄8 370 518 538 518 166.5 203⁄8 213⁄16 203⁄8 335 518 538 518 150.8 141⁄2 163⁄8 141⁄2 137 368 416 368 61.7 141⁄2 163⁄8 163⁄8 715⁄16 245⁄16 145 141⁄2 163⁄8 141⁄2 125 368 416 416 202 617 65.3 368 416 368 56.3 41⁄8 67 93⁄8 163⁄8 127⁄8 81 41⁄8 127⁄8 127⁄8 63 93⁄8 163⁄8 163⁄8 93⁄8 253⁄4 103 127⁄8 163⁄8 163⁄8 93⁄8 253⁄4 119 127⁄8 163⁄8 127⁄8 101 105 30.2 238 416 327 36.5 105 327 327 28.4 238 416 416 238 654 46.3 327 416 416 238 654 53.6 327 416 327 45.3 3 76 2 ⁄8 60 3 13⁄4 44 D D C A B • NA - not available • Consult factory for dimensions of 15,000 psi sour gas swivel joints and 20,000 psi standard service swivel joints. 1. Three inch size only with Weco wing union end connections. Notes 102 (89) 4 (31⁄2) 76 (70) 3 3 (2 ⁄4) 51 (48) 2 (17⁄8) 38 (33) 11⁄2 (1.3) 25 (22) 1 (7⁄8) Sizes (inches) (mm) A A B Longsweep and TripleStep1 swivel joints Chiksan Swivel Joint Specifications Chiksan Cementing and Circulating Hoses C hiksan cementing and circulating hoses can handle a complete range of fluids at cold working pressures up to 20,000 psi. These rugged, all-steel hoses are available in sizes and configurations to meet virtually any need. All materials meet ASTM or AISI standards. High-pressure hose One Weco union and two Style 50 or Style 10 Chiksan swivel joints with threaded ends Recommended Service High-pressure discharge lines, water lines, temporary flow lines, well testing lines, and cementing and circulating lines, and other highpressure applications. TS-15 Longsweep hose Features & Benefits Four Weco unions and two Style 50 or Style 10 TripleStep swivel joints with integral Weco union ends Chiksan swivel joints: FMC all steel hoses feature Chiksan swivel joints which provide flexibility, absorb shock and vibration, and maximize flow characteristics. Weco wing union connections: Weco wing union end connections insure fast, pressure-tight make-up and break-out without threading, welding, or special connections. LS-15 Longsweep hose One Weco union and one each Style 50 and Style 10 Longsweep swivel joints with integral Weco union ends Simplifies transportation and layout: Chiksan hoses fold up easliy and quickly for transportation and storage. Available for sour gas service: Chiksan cementing and circulating hoses are available for sour gas services at cold working pressures up to 15,000 psi. LSG-10 Longsweep hose Four Weco unions and two Style 50 or Style 10 Longsweep swivel joints Quick Reference Chart Chiksan Models High-Pressure Swivel Joints Extra High-Pressure Swivel Joints Longsweep Swivel Joints Longsweep TripleStep Swivel Joints Color Code Method of Construction Threaded NPS Integral Welded Cold Working Pressure, psi Sizes, in. 1 11⁄2 2 3 4 Weco fig. no. Olive Green (Sour Gas) 6,000 602 Silver 6,000 602 Black 10,000 1502 Olive Green (Sour Gas) 7,500 1002 Olive Green (Sour Gas) 10,000 1502 Olive Green (Sour Gas) 15,000 2202 Black 10,000 1502 Black 10,000 1002 Red 15,000 1502 Light Blue 20,000 2002 Red 15,000 1502 10 Chiksan Mud Mixing Guns C hiksan mud mixing guns are used to blend and agitate drilling mud in either tanks or pits. All models feature Chiksan swivel joints for smooth rotation and durability. Chiksan mud guns are also equipped with replaceable tungsten-carbide nozzles. Materials meet ASTM and AISI standards. Chiksan Nonspin Mud Mixing Guns 2,000 psi (138 bar) cold working pressure; 2-inch size Recommended service Chiksan Spinner Mud Mixing Guns Chiksan Bottom-Type Mud Mixing Guns 2,000 psi (138 bar) cold working pressure; 2-inch size 2,000 psi (138 bar) cold working pressure; 2-inch size Recommended service Recommended service Bottom of tank use where constant agitation is required Bottom of tank where large volumes of mud must be mixed Features Features • Self-rotating design • Available for any depth tank • Mounts in center of tank • Maintains uniform mixture, prevents heavy material from settling • Available with extra-large 3-inch bore at 300 psi (21 bar) cold working pressure • Adaptable to any tank depth • Mounts at side of tank; can be directed by hand Top of tank or pit use where large volumes of mud must be mixed; jetting mud from one tank to another Features • Suitable for stationary or hand-guided operation; may be left unattended • Moves freely in horizontal and vertical directions; locks securely in position with pin locks Nonspin-type Spinner-type Bottom-type, 2-in. 11 Bottom-type, 3-in. Chiksan Circulating Heads T he Chiksan all-steel circulating head makes it possible to circulate fluid and rotate drill pipe with the rotary table while drilling is interrupted for wireline operations. Circulation and rotation minimize the risk of stuck drill pipe. The ability to circulate mud also provides additional pressure control in case of a well kick. Adapters are available for connecting this 6,000 psi, field-proven tool to tubing, drill pipe, casing, or tool joint. Wireline stuffing box can be mounted on top of the circulating head. All body materials meet ASTM or AISI standards. Recommended service Wireline coring operations, fishing jobs, and directional surveys How To Order C hiksan products for drilling and production applications are available through recognized oilfield supply stores. To order Chiksan products for other applications or services, consult FMC Fluid Control Division. Because Chiksan products vary to meet particular service conditions, it is necessary to include the following information when placing an order. Chiksan swivel joints 1. Swivel joint type (low pressure, Longsweep, etc.) 2. Pipe size 3. Style number of swivel joint (see page 4) 4. Material of construction 5. End connections 6. Product being handled (if acid, give concentration) 7. Cold working pressure and maximum pressure 8. Operating temperature and maximum temperature Chiksan cementing and circulating hoses 1. Size (diameter and length) 2. Product being handled (if acid, give concentration) 3. Cold working pressure and maximum pressure 4. Operating temperature and maximum temperature 5. Swivel joint configuration (50/50, 10/10, 50/10) 6. End connections Chiksan mud mixing guns 1. Mud gun type (nonspin, spinner, bottom-type) 2. Pipe size 3. Length 12 Chiksan circulating heads 1. Pipe size 2. Adapter type (standard, female line pipe threads, male line pipe threads) Chiksan lubricants 1. Type of lubricant 2. Size of container Replacement packing 1. Pipe size and type of joint 2. Code number on casting or forging 3. Type of product being handled (if acid, give concentration) 4. Maximum operating pressure 5. Operating temperature Warnings and Safety Instructions F MC can not anticipate all of the situations a user may encounter while installing and using FMC products. Therefore, the user of FMC products MUST know and follow all applicable industry specifications on the safe installation and use of these products. Refer to FMC product catalogs, product brochures and installation, operating and maintenance manuals for additional product safety information or contact FMC at 800/772-8582. WARNINGS FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH! 1. Do not mix or assemble components, parts or end connections with different pressure ratings. Mismatched parts may fail under pressure. 2. Do not use or substitute non FMC components or parts in FMC products and assemblies. 3. Do not strike, tighten or loosen pressurized components or connections. 4. Do not exceed the rated working pressure of the product. 5. Complete and proper make-up of components and connections is required to attain rated working pressure. 6. Do not use severely worn, eroded or corroded products. Contact FMC for more information on how to identify the limits of erosion and corrosion. 7. Follow safe practices when using products in overhead applications. Products not properly secured could fall. 8. Select only appropriate product and materials for the intended service: • Do not expose standard service products to sour gas fluids. (Refer to NACE MR-0175.) Do not interchange sour gas components with standard service components. • Use appropriate safety precautions when working with ferrous products in below freezing temperatures. Freezing temperatures lower the impact strength of ferrous materials. 9. Follow manufacturers instructions and Material Safety Data Sheet directions when using solvents. 10. Make certain that personnel and facilities are protected from residual hazardous fluids before disassembly of any product. 11. If any leakage is detected from FMC products, take them from service immediately to prevent potential damage and personal injury. SAFETY INSTRUCTIONS The applications of FMC products are in working environments where general personnel safety procedures and policies MUST be followed. Always use appropriate protective equipment in high pressure, extreme temperature or severe service applications. FMC Corporation Fluid Control Division Fluid Control Headquarters 6677 North Gessner Road Houston, Texas 77040 Phone: 713/510-6800 Fax: 713/510-6803 E-mail: fluid_control@fmc.com http://www.fmc.com/Eteg/ (Direct orders to sales offices at the following locations:) FMC Fluid Control Division 2825 West Washington P.O. Box 1377 Stephenville, Texas 76401 Phone: 1-800-772-8582 Fax: 2547/968-5709 FMC Corporation (U.K.) Ltd. Fluid Control Division Wellington Road Industrial Park Wellington Circle Aberdeen AB12 3JG Scotland Phone: (44) 1224/898-555 Fax: (44) 1224/249-460 FMC Southeast Asia Pte. Ltd. Fluid Control Division 149 Gul Circle Singapore 629605 Phone: (65) 862-3659 Fax: (65) 861-8251 FMC International S.A. Fluid Control Division Al Moosa Tower, 17th Floor Box 3228 Dubai, United Arab Emirates Phone: (971) 4/310-948 Fax: (971) 4/310-950 ©Copyright 1997, FMC Corporation Printed in U.S.A., HP 5.0M 3-97