CUSTOMER TRAINING

advertisement

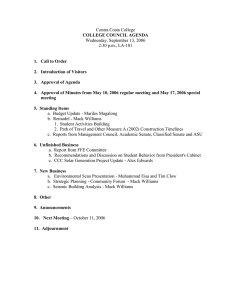

CUSTOMER TRAINING Courses for Service Technicians 1 TRAINING MACK TECHNICIANS FOR FAST, ACCURATE SERVICE THE MACK MASTER FLEET TECHNICIAN TRAINING PROGRAM Mack Trucks Academy makes training easy and effective. Our course offerings deliver a wealth of valuable OEM training that goes right to your bottom line. We offer eLearning courses designed for 24/7 convenience, plus instructor-led classes at our Academy training centers or on-site at your shop. The Mack Master Fleet Technician training program lets you build the competence of your technician talent pool. It also helps you retain valuable employees by training them to be experts in efficient and effective Mack truck repair. There are two training paths to choose from: one with Mack engines and one without. Added Value for Your Fleet. A properly trained team of technicians—prepared to tackle any repair challenge—sets you apart from the competition. Highly skilled technicians contribute to customer satisfaction by increasing uptime and improving shop efficiency. PROFESSIONAL TRAINING AT ALL OF OUR LOCATIONS Allentown, PA 2402 Lehigh Parkway South Allentown, PA 18103 Dallas, TX 1360 Post & Paddock Road Grand Prairie, TX 75050 Atlanta, GA 200 Tradeport Boulevard Suite 212 Atlanta, GA 30354 Toronto, ON 6155 Belgrave Road, Unit 2 Mississauga, ON, L5R 4E6 Chicago, IL 3900 Rock Creek Blvd Joliet, IL 60431 Quebec, QC 2775 rue de L’Etchemin Saint Romuald, QC G6W 7X5 GETTING STARTED We’ll be glad to discuss your specific training requests and goals for your technicians. Contact us by email, and we’ll be in touch to explore the curriculum, location, and timetable that work best for you. For information and enrollment, please contact academy-help@macktrucks.com. 2 ONLINE TECHNICIAN TRAINING: General Repairs and Preventative Maintenance Lubrication Training 1 – Fundamentals of Lubrication Lubrication Training 2 – Heavy-Duty Diesel Engine Lubrication Lubrication Training 3 – Heavy-Duty Truck Gear Lubrication Lubrication Training 4 – Heavy-Duty Truck Grease Lubrication Lubrication Training 5 – Heavy-Duty Coolants / Anti-Freeze Mack Preventive Maintenance Systems, Operations, Basic Diagnostics and Repair Mack Air Brake Fundamentals Introduction to Electrical Systems Introduction to Mack Electronics Mack Operating 2007 and Newer Vehicles Mack Basic Heavy-Duty Truck HVAC Principles Diesel Engine Basics Impact for Fleets Heavy-Duty Truck Transmission Basics Mack mRide™ and Twin Y™ Suspensions Overview Mack Co-Pilot Overview Program Service Diagnostic Systems and Major Repair Premium Tech Tool 2.0 for Mack Trucks Mack Trucks HD-OBD Basics Mack SCR Familiarization Mack M1 Engine Measuring Tools Bendix ABS 6 Advanced with ESP Stability System Catalyzed DPF Non-Catalyzed DPF Mack Exhaust Aftertreatment System (EATS) Overview Mack 2013 Communication Network Update Advanced Level Diagnostics Failure Analysis Mack Automated Transmission for Fleets Mack mDRIVE™ How to Remove Control and Range Housing Mack Air in the Fuel System, Check Mack Engine Injector and Sleeve, Replacement (Conical) Contact your local dealer or academy-help@macktrucks.com to enroll. 3 GENERAL REPAIRS AND PREVENTATIVE MAINTENANCE Lubrication Training I Fundamentals of Lubrication This course reviews the essentials of lubricationfor service technicians, including friction, viscosity, viscosity grades and wear. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Identify the characteristics of friction Identify the qualities of lubrication viscosity and its effects on moving parts Identify the conditions potentially leading to component failures Lubrication Training II - HeavyDuty Diesel Engine Lubrication This course reviews the fundamental components of a heavy-duty diesel engine and its lubrication needs. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Identify mechanical components of a heavyduty diesel engine and their lubrication needs Lubrication Training III - HeavyDuty Truck Gear Lubrication This program provides basic information on gearbox types and operation, gearbox lubrication, gearbox maintenance, and gear lubricants. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Identify the gearbox types and operation Recognize transmission basics Describe gearbox lubrication, gearbox maintenance and gear lubrication challenges Lubrication Training IV - HeavyDuty Truck Grease Lubrication This course defines grease, reviews different applications of great lubrication, covers grease performance specifications and details proper grease lubrication procedures. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Recognize and understand what grease is and the typical truck parts that require grease Identify the testing done to determine grease performance specifications, and the proper methods use to apply grease Lubrication Training V HeavyDuty Coolants / Anti-Freeze Introduction to Mack Electronics Describe engine cooling system parts and operation List the coolant/anti-freeze protection characteristics List the coolant/anti-freeze performance specifications Recognize the coolant/anti-freeze challenges Identify the four versions of the V-MAC system Describe the key components and the general operation of the V-MAC electronic engine control system Recognize the key V-MAC IV sensors, control modules, actuators, control switches, dash indicator lamps and their associated functions This course provides a basic understanding of engine cooling system parts and operation, including coolant properties and potential problems, coolant/anti-freeze performance specifications, and coolant/anti-freeze challenges. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Mack Preventive Maintenance This course is designed to cover the essential items necessary to properly maintain a MACK truck. 45 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe preventive maintenance and preventive maintenance schedules Identify the need and benefits of oil analysis Explain the use of V-MAC and VCADS through Premium Tech Tool (PTT) SYSTEM, OPERATIONS, BASIC DIAGNOSTICS AND REPAIR Mack Air Brake Fundamentals This course provides an overview of the components and systems related to the operation of an air-equipped chassis and air brake systems for new technicians. Piping diagrams will be used to accurately illustrate air flow through the system. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe the typical air generation system Explain the primary air system circuit Explain the secondary air system circuit Recognize the dual air circuit Identify the tractor protection manifold Identify the spring brake control Introduction to Electrical Systems The purpose of this course is to define electricity and explain electrical circuit types, components, and systems. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Explain how electricity is measured Relate Ohm’s Law and Joule’s Law to the different circuit classifications Troubleshoot the starter motor and charging system Troubleshoot a circuit for faults 4 This course is designed to introduce technicians to the operation and diagnosis of the V-MAC® electronics system. Training begins with an overview of the early V-MAC systems and then focuses on the details of the current system the V-MAC IV. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Mack Operating 2007 and Newer Vehicles This course guides the participant through the operation of US’07 and newer MACK vehicles. It is organized into 3 modules: (1) Chassis, Cab Controls and Indicators Overview, (2) Engine Operation & Fuel Economy and (3) US’07 Exhaust After Treatment System. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Locate the chassis, engine and transmission information for MACK vehicles Plan your pre-trip inspection Identify and describe the key indicators and cab controls Adjust the driver’s seat, seatbelt, and steering wheel in ’07 and newer Mack vehicles Mack Basic Heavy-Duty Truck HVAC Principles This course is structured in three learning modules: (1) Basic principles of refrigeration, (2) component identifications along with brief explanations of each function and (3) overview of refrigerant handling and the equipment needed to evacuate, recharge and test for leaks. 45 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe the heat transfer and Freon characteristics Identify the basic concepts in diagnosing heater and air conditioning complaints Diesel Engine Basics The purpose of this course is to detail the diesel engine parts and components, and explain how power is made. 45 Minutes Objectives Upon successful completion of this course, participants will be able to: Translate how the idea for a compression ignition/diesel internal combustion engine came about Describe the parts and components in a standard diesel engine Describe the four-stroke Otto cycle for a diesel engine Translate how power is made in a diesel engine Describe the advantages of a diesel engine Impact for Fleets In this course, participants learn how to use the key features of Impact—a helpful tool that allows you to search for parts, components and service information. 30 Minutes Objectives Upon successful completion of this course, participants will be able to: Identify and explain Impact’s major functions common to parts and service users Heavy-Duty Truck Transmission Basics This course explains the physics behind how a transmission works, why a transmission is needed, what it does, and how it performs. 40 Minutes Objectives Upon successful completion of this course, participants will be able to: Understand why a transmission exists and how it functions Recognize how pairs of gears work together to provide a mechanical advantage Appreciate the inverse relationship between torque and speed Understand the components that make up a transmission Understand the power flow through a transmission Discover how to properly shift a transmission Mack mRide™ and Twin Y™ Suspensions Overview Identifies and explains the features, benefits, and correct applications of the Twin Y™ and mRide™ suspension. 15 Minutes Objectives Upon successful completion of this course, participants will be able to: Identify and explain the features, benefits, and correct applications of the mRide™ suspension Identify and explain the features, benefits, and correct applications of the Twin Y™ suspensions Mack Co-Pilot Overview Program This eLearning program provides Mack dealerships with basic information on Mack Co-Pilot and how vehicle operators can use Co-Pilot to maximize productivity. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Explain what the Mack Co-Pilot is Describe how Co-Pilot helps to maximize productivity Recall basic navigation of the Co-Pilot driver information display SERVICE DIAGNOSTIC SYSTEMS AND MAJOR REPAIR Premium Tech Tool 2.0 for Mack Trucks The goal of this course is to introduce technicians to the new version of Premium Tech Tool (PTT). 30 Minutes Objectives Upon successful completion of this course, participants will be able to: Navigate the new interface Differentiate between the new and old functions within the system Use the new system to diagnose and test a product Mack Trucks HD-OBD Basics This course is designed to cover what Heavy Duty-On Board Diagnostics is, and why it is necessary for heavy-duty vehicles. 90 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe HD-OBD Describe the MIL Identify DTCs including what they are and what causes them to set Identify a complete drive cycle Identify Functional Monitors Identify Comprehensive Monitors Identify Threshold Monitors Describe PTT functionality as it relates to HD-OBD Identify standardized terminology Mack SCR Familiarization This course provides an introduction to the new exhaust aftertreatment technology, called selective catalytic reduction, or SCR, used on EPA’10 certified MACK trucks. It reviews components, system operation, driver indications, maintenance considerations, and diagnostics. 120 Minutes Objectives Upon successful completion of this course, participants will be able to: Recognize the importance of the use of only approved Diesel Exhaust Fluid (or DEF) for EPA’10 trucks Explain the operation of the Selective Catalytic Reduction (SCR) system Describe the necessity to avoid contaminating the DEF and SCR system Recognize how DPF regens have changed for EPA’10 trucks Apply basic knowledge of the control system and datalink connections used Identify new driver indications, including the MIL lamp and DEF low level indicator Recognize basic SCR system maintenance concerns, including the proper protection of electrical terminal and connections Illustrate how to read and repair fault codes on US’10 trucks Mack M1 Engine Measuring Tools This prerequisite online course will familiarize participants with the use of a micrometer and dial indicator to evaluate whether a part is worn beyond specifications or whether it is installed properly. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Take measurements correctly Manage to set up, measure and read results Identify the results to specifications Bendix ABS 6 Advanced with ESP Stability System This course will familiarize service technicians with Mack Road Stability Advantage with Adaptive Cruise Control, sometimes known as “Bendix Wingman Advanced.” This course focuses on wheel speed sensors, modulators, ECU, ESP sensors, stability overview, diagnostic tools and troubleshooting. 60 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe, troubleshoot, diagnose and service the Bendix ABS-6 Braking System accurately and efficiently 5 Catalyzed DPF This training begins with a fundamental explanation of Diesel Particulate Filters, continues on to detail the DPF system components and normal operation of the DPF, and ends with fault diagnosis and the driver interface display. 180 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe the purpose of a DPF and how it functions Identify the components, sensors and control modules that make up the Catalyzed DPF Identify the DPF regeneration process, the inspection, maintenance and component replacement criteria Demonstrate how to diagnose a Catalyzed DPF using Guided Diagnostics Recognize all DPF-to-Driver messages, warning lamps, labels, switches and controls Non-Catalyzed DPF The purpose of this course is to define the non-catalyzed DPF and its sub-components, explain the proper operation of the filter, and detail the maintenance and diagnosis of the DPF. 180 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe the purpose of a DPF and how it functions Recognize the components, sensors and controls modules that make up the noncatalyzed DPF Describe the DPF regeneration process; the inspection, maintenance and component replacement criteria Demonstrate how to diagnose a noncatalyzed DPF using guided diagnostics Recognize all DPF-to-driver messages, warning lamps, labels, switches and controls Mack Exhaust Aftertreatment System (EATS) Overview 2013 Communication Network Update for Mack Trucks Mack Air in the Fuel System, Check Navigate the new interface Identify the flow of fluid through the fuel supply system Properly perform an air in the fuel system, check according to published guidelines Interpret results of an air in the fuel system, check This course introduces the new ISO communication network, how it works, and how the vehicle has changed to accommodate this new network. The new network complies with 2013 EPA requirements regarding general diagnostic scanners for non-dealership technicians. 12 Minutes Objectives Upon successful completion of this course, participants will be able to: Differentiate between the new and old functions within the system Use the new system to diagnose and test the vehicle ADVANCED LEVEL DIAGNOSTICS Mack Engine Injector and Sleeve, Replacement (Conical) Failure Analysis This video course demonstrates the proper procedures and lists the correct information and tools required to inspect, remove and replace conical injectors and sleeves. 30 Minutes Objectives Upon successful completion of this course, participants will be able to: Diagnose the root cause of failures using the failure analysis process Identify all contributing causes of failure Perform repairs Recognize any conditions that may need correction to prevent a repeat failure Perform proper removal procedures with updated tools Identify proper cleaning procedures for conical sleeve reuse, removal, and replacement Determine reusability of the conical sleeve and injector Identify and assemble new conical injector sleeve tooling Identify proper cleaning procedures for conical injector reuse, removal, and replacement Perform proper installation procedures with updated tooling This online course provides students with the training necessary to properly diagnose the root cause of component failures with engines, transmissions and carriers. 120 Minutes Objectives Upon successful completion of this course, participants will be able to: Mack Automated Transmission for Fleets This course introduces the student to the Mack mDRIVE™ automated transmission including the gear selectors, components, lubrication system and operation. 35 Minutes Objectives Upon successful completion of this course, participants will be able to: In this course, technicians learn how to identify the different MACK® CT™ Exhaust Aftertreatment System Components, and learn how the system operates. Terminology is defined regarding each system component and operation, with training on diagnosing issues with the Exhaust Aftertreatment System. 30 Minutes Objectives Upon successful completion of this course, participants will be able to: Describe features and benefits of the Mack mDRIVE™ Identify components of the Mack mDRIVE™ Describe the lubrication system for the Mack mDRIVE™ Identify the different system components and how the system operates Recognize terminology related to each system component and operation Diagnose issues with the Exhaust Aftertreatment System This course demonstrates the proper procedures to remove the transmission range housing, transmission ECM, and transmission control housing, both manually and electronically, using VCADS. 15 Minutes Objectives Upon successful completion of this course, participants will be able to: Mack mDRIVE™ — How to Remove Control and Range Housing Identify the proper procedures, information, and tools to remove the transmission range housing, transmission ECM, and transmission control housing, both manually and electronically, using VCADS Recognize the outcome of following proper procedures 6 The purpose of the “Air in the Fuel System, Check” video is to familiarize you with the engine fuel supply system and guide you through the proper tests to determine if any aeration exists. The video will also demonstrate how to interpret the results of the fuel system tests. 15 Minutes Objectives Upon successful completion of this course, participants will be able to: INSTRUCTOR-LED TECHNICIAN TRAINING AVAILABLE INSTRUCTOR-LED COURSES Engines Design and function Maintenance Tune-up procedure Diagnostics Engine overhaul Aftertreatment systems Electronics Design and function Component location Module communications Sensor operation and location Parameter programming Troubleshooting and diagnostics Premium Tech Tool to include Guided Diagnostics and VCADS Electrical Design and function Circuit identification Wire ID and nomenclature Reading wiring schematics Starting and charging circuits You have your own training needs and timetables. That’s why we offer instructor-led training that’s custom-designed to fit your requirements. These best-in-industry courses can be scheduled in one of our five training facilities or onsite at your location. Diagnostics All courses are facilitated by Mack Trucks Academy trained instructors who have real-world experience repairing Mack trucks in dealerships and/or service operations. They understand the demands and challenges of working in a fast-paced, bottom-line-driven service department. Air system generation Mack technician training at one of our classroom locations assures a learning experience that’s comprehensive, comfortable and free of distractions. If you would rather host an exclusive training event at your location or a site of your choosing, we offer on-site training as well. You’ll work directly with the training instructor to customize the course material, class schedules and equipment needed for proper hands-on training. Brakes Design and function Foundation brakes Brake electronics and diagnostics System and electronic diagnostics HVAC Heating, Ventilating & Air Conditioning Performance testing Refrigerant recovery and charging Preventive Maintenance For a listing of available scheduled fleet courses, visit macktrucks.vg-emedia.com PM schedule Contact academy-help@macktrucks.com for more information on training costs and availability. Lube point locations Chassis requirements and adjustments 7 Mack Trucks Academy 7900 National Service Road Greensboro, NC 27235 www.macktrucks.com ©2016 Mack Trucks 8