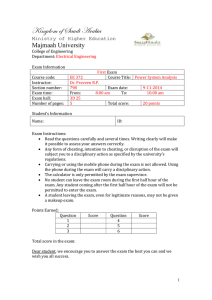

study

advertisement