Sidewall Propeller Fans

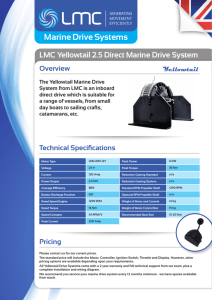

advertisement